A magic wand automatic production device

A technology of automatic production and magic wand, which is applied to household appliances, other household appliances, household components, etc., can solve the problems of high labor intensity and low production efficiency of employees, and achieve the effect of reducing labor intensity of employees and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

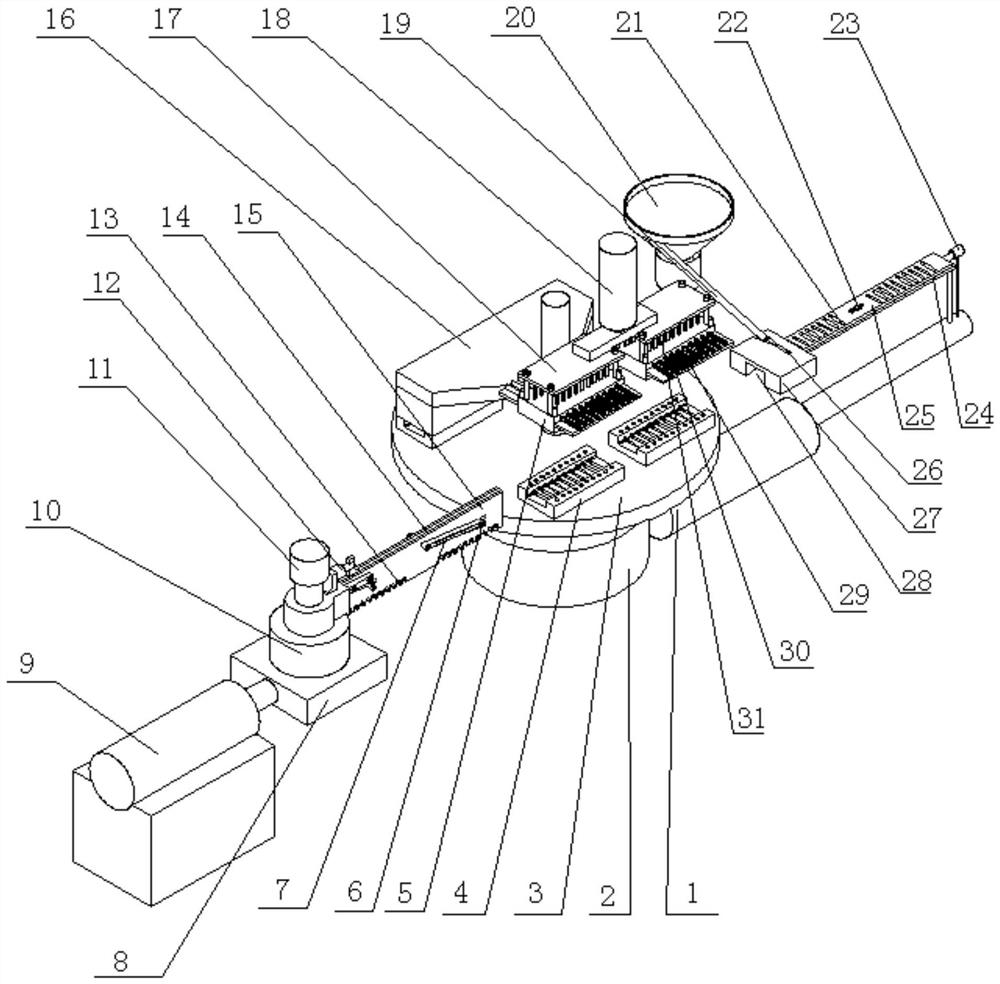

Image

Examples

Embodiment 1

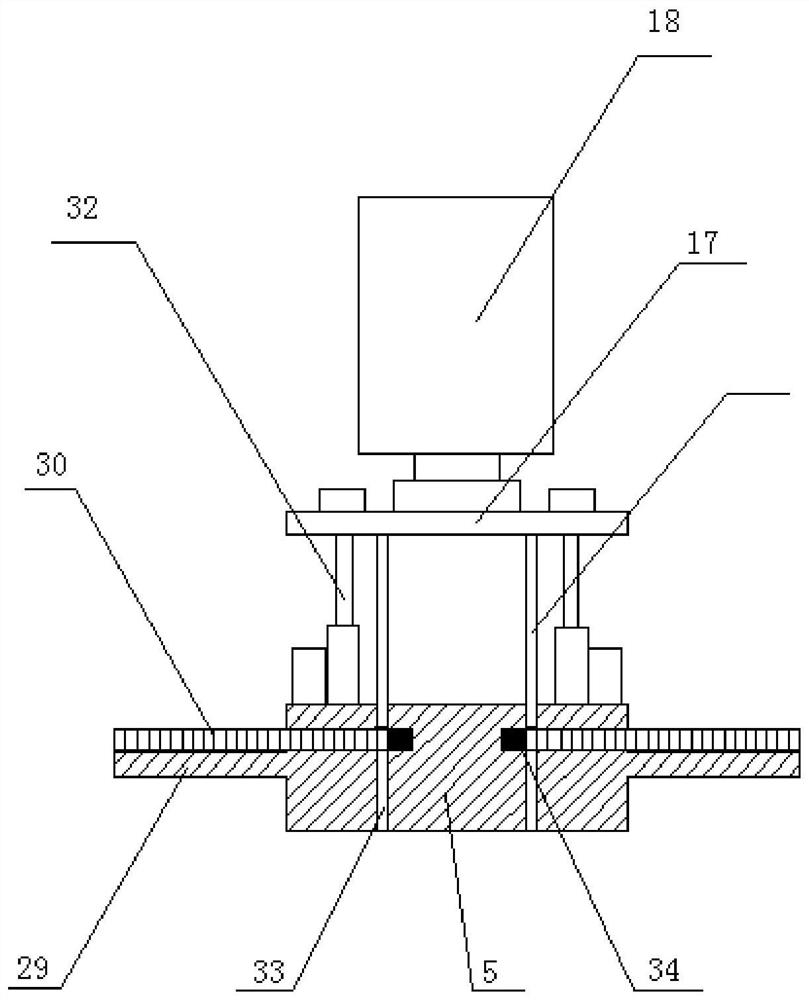

[0026] Example 1: Such as figure 2 As shown, the telescopic mechanism is a telescopic rod 32, and the relative movement between the fixed plate 17 and the lifting plate 5 is realized by the telescopic rod 32. It should be noted that the two ends of the telescopic rod 32 are connected to the fixed plate 17 and the lifting plate 5 respectively. stable.

Embodiment 2

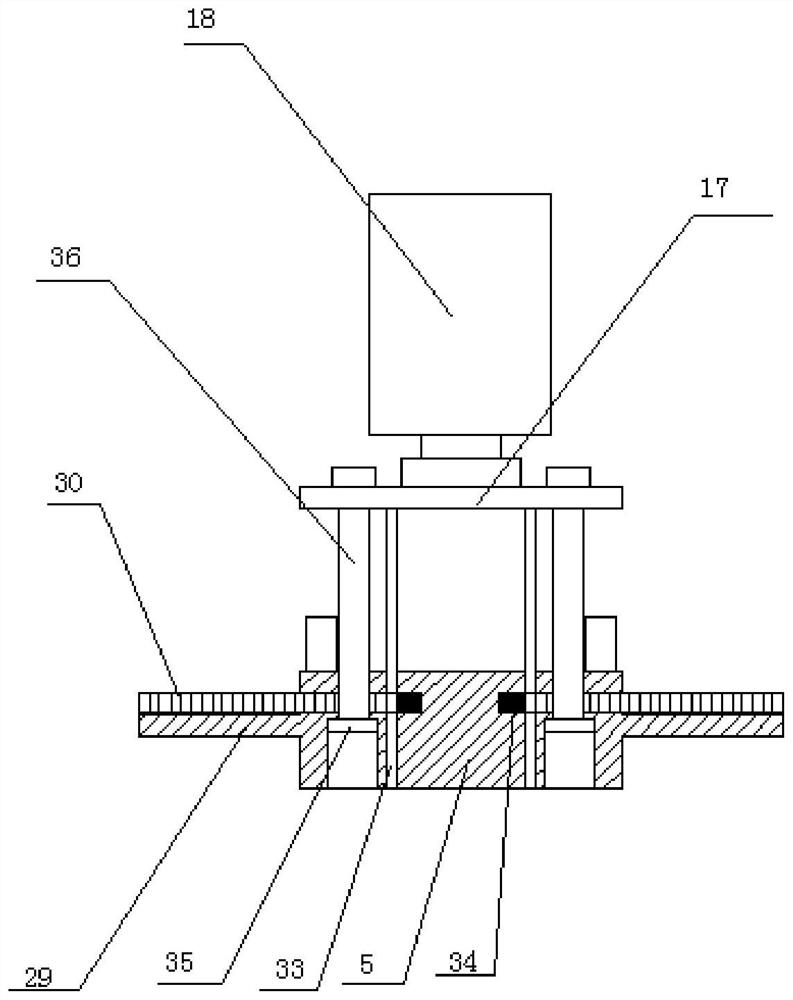

[0027] Example 2: Such as image 3 As shown, the telescopic mechanism includes a sliding rod 36 fixed at one end to the fixed plate 17, and the end of the sliding rod 36 facing away from the fixed plate 17 is provided with a limit block 35. The lifting plate 5 is provided with a sliding rod 36 and The limit block 35 is matched with the sliding groove and the receiving groove, and the limit block 35 is used to clamp the sliding rod 36.

[0028] In this embodiment, the supporting plate 29 is preferably provided on both sides of the lifting plate 5, and the supporting plate 29 can support the magnetic core 30 to prevent the magnetic core 30 from being skewed due to inertia when the magnetic core 30 moves up and down. on.

[0029] The preferred feeding device of this embodiment includes a positioning plate 27 and a screw feed hopper 20. The positioning plate 27 is provided with a conveying hole 28, and a first feeding plate 24 and a second feeding plate 24 are slidably provided in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com