Catheter joint injection molding device

A catheter connector and catheter technology, applied in the field of catheter connector injection molding device, can solve the problems of long production cycle and high process cost, achieve high degree of automation, simplify the connection process, and ensure the effect of precise requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

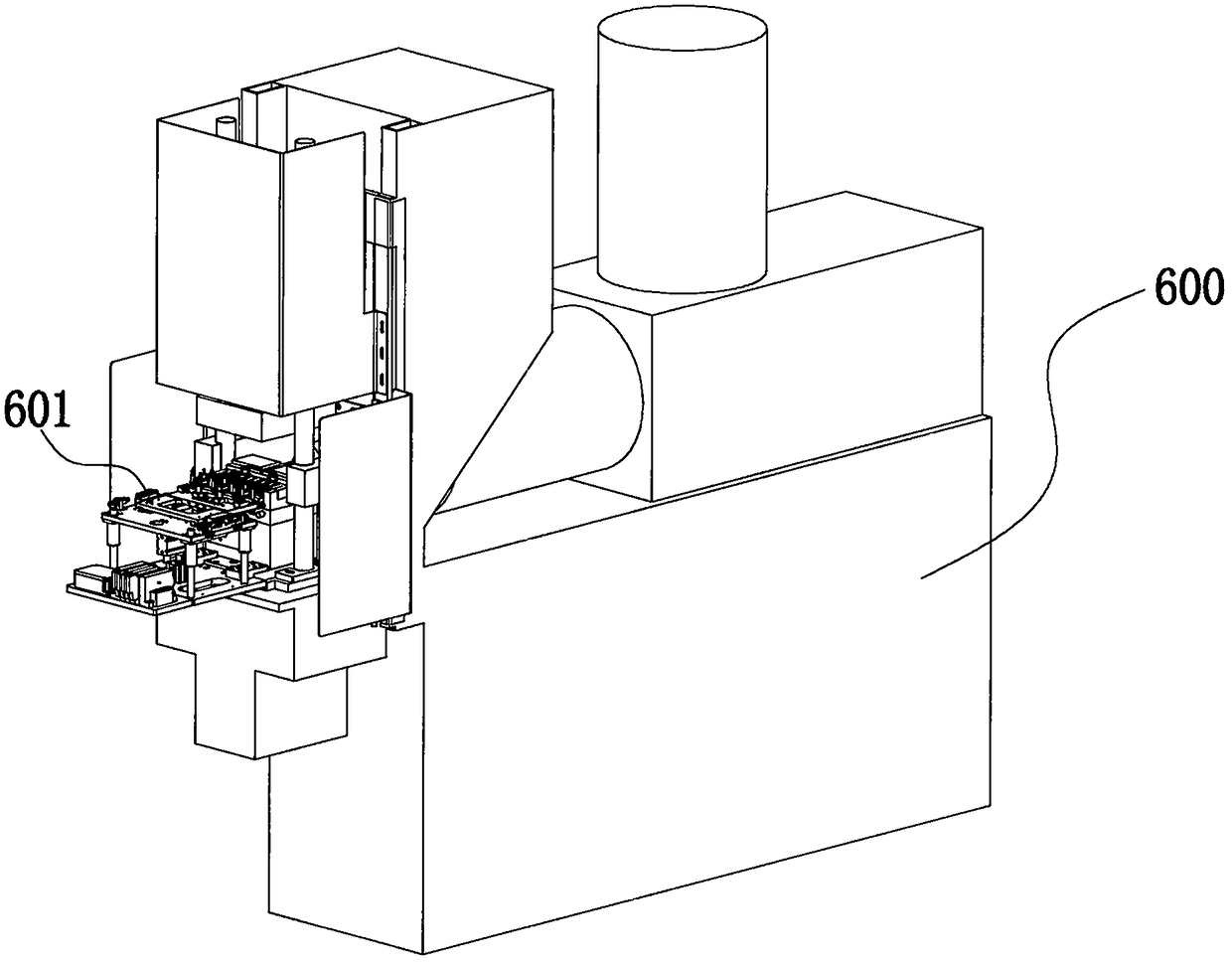

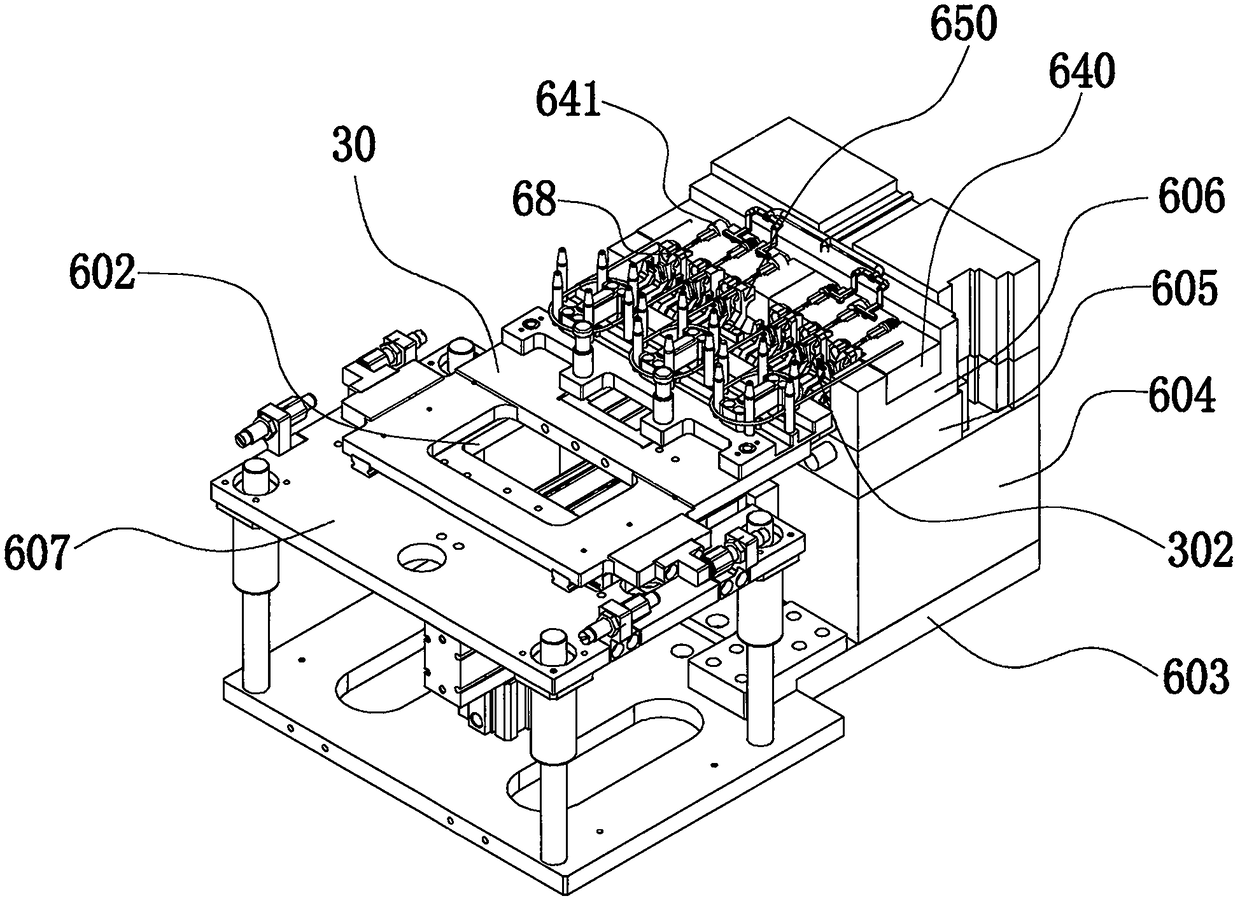

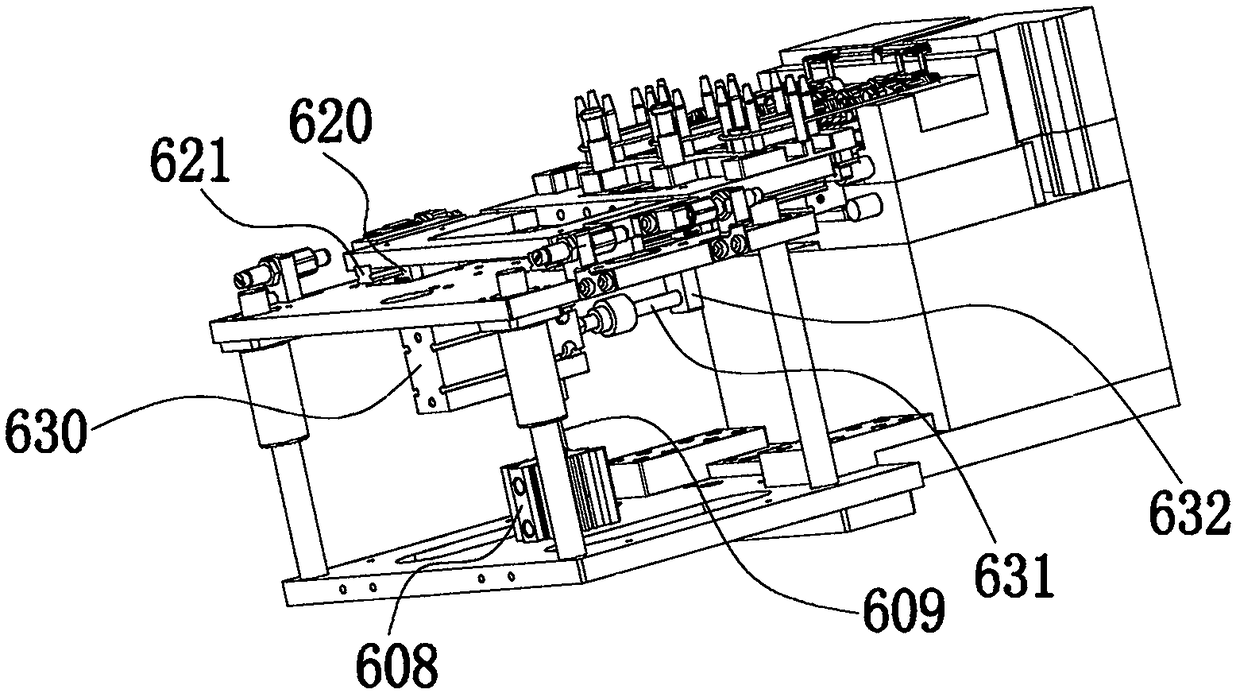

[0028] Such as Figure 1-3 As shown, a catheter joint injection molding device includes an injection molding machine 600, a mold bottom plate 603, a support block 604 fixed on the mold bottom plate 603 in turn, a first backing plate 605 and a second backing plate 606; on the second backing plate 606 An upper mold plate 640 is fixed, and a plurality of catheter joint molds 641 corresponding to the medical catheter 32 are fixed on the upper mold plate 640, and a clamping and positioning device 650 for positioning the medical catheter 32 is fixed on the first backing plate 605; The clamping and positioning device 650 corresponds to the position of the conduit joint mold 641; the middle part of the mold bottom plate 603 is provided with a driving cylinder 608, the driving cylinder 608 is connected with a driving shaft 609, and the driving shaft 609 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com