Self-adaptive glass gripping sucker

A self-adaptive, sucker technology, applied in conveyor objects, furnaces, conveyors, etc., to achieve the effect of no safety hazards, improve production efficiency, and save working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

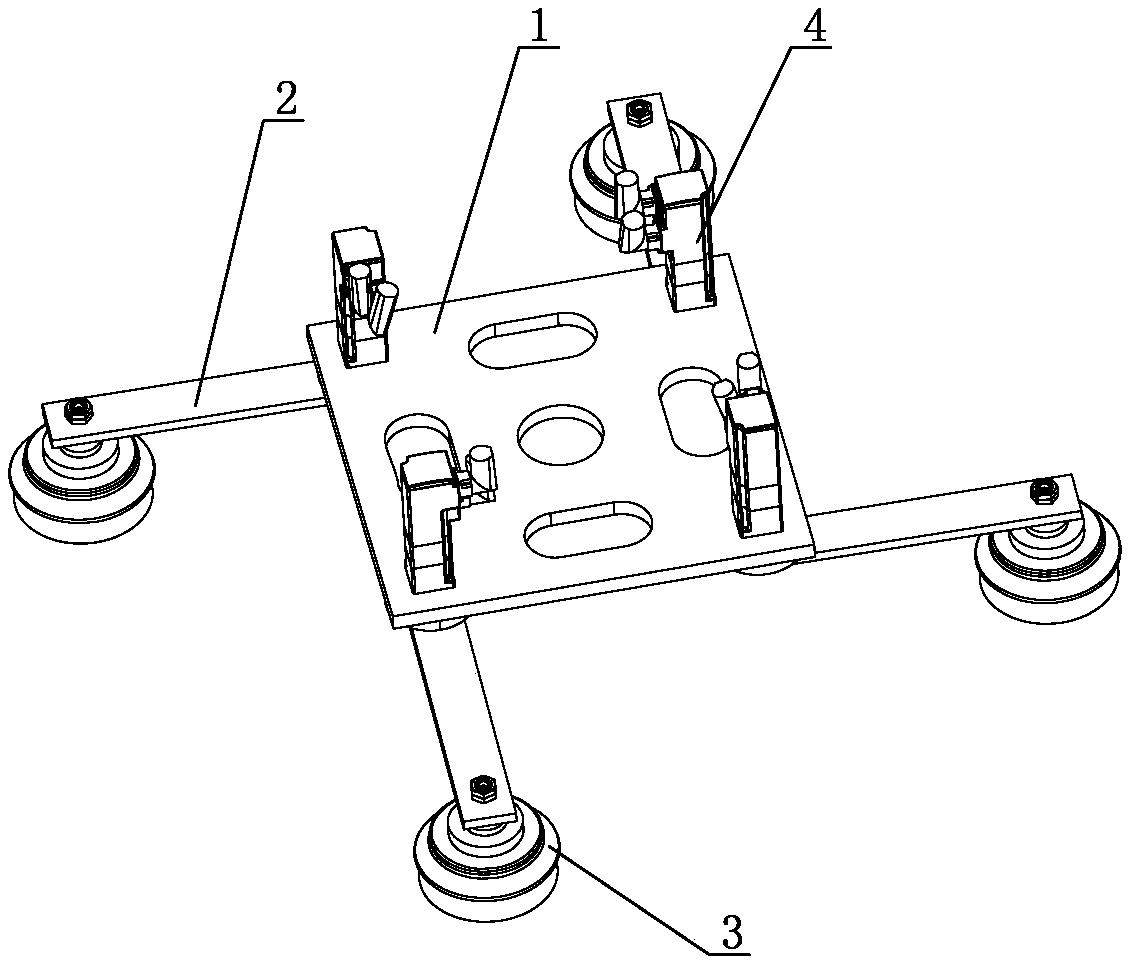

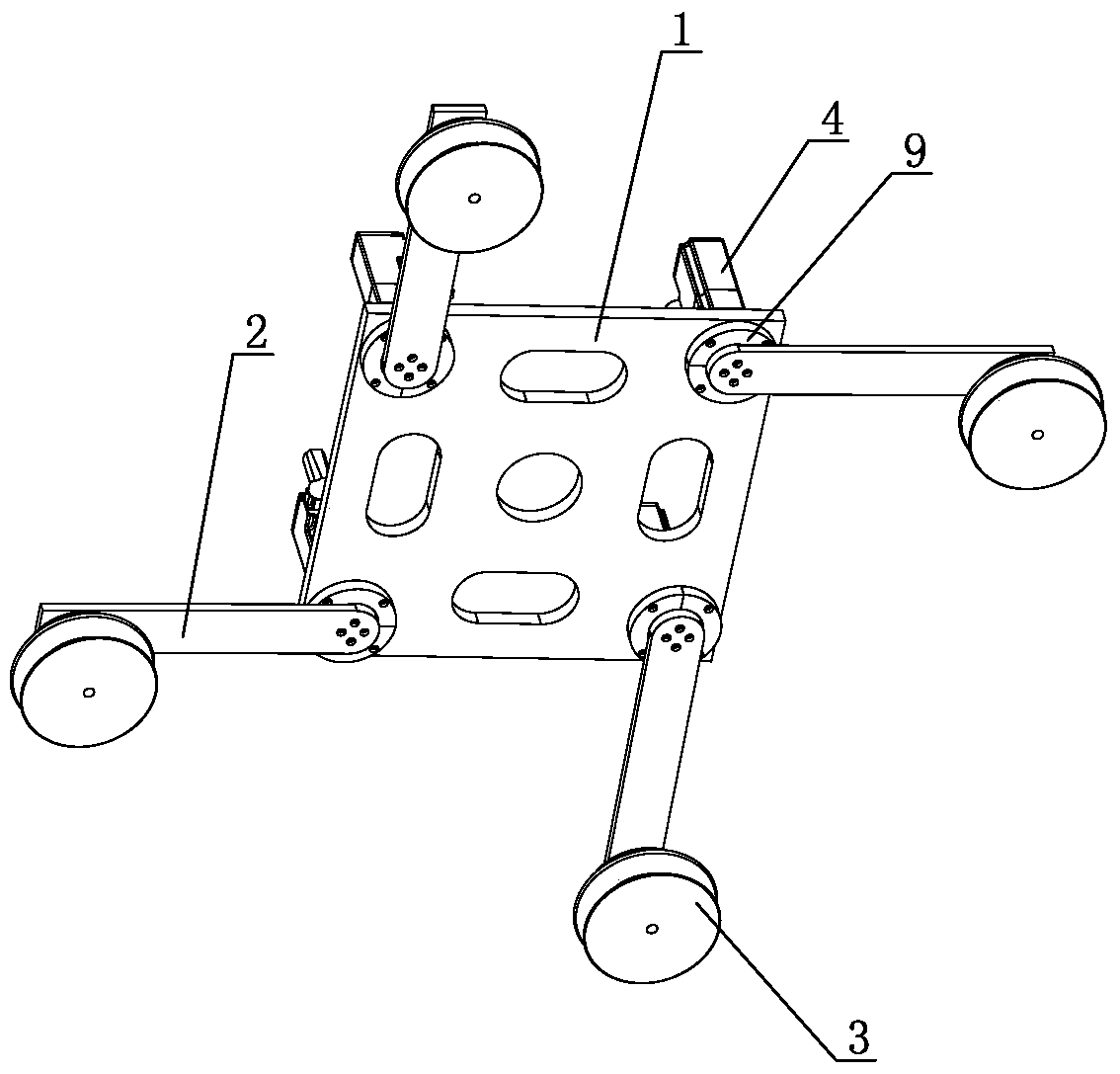

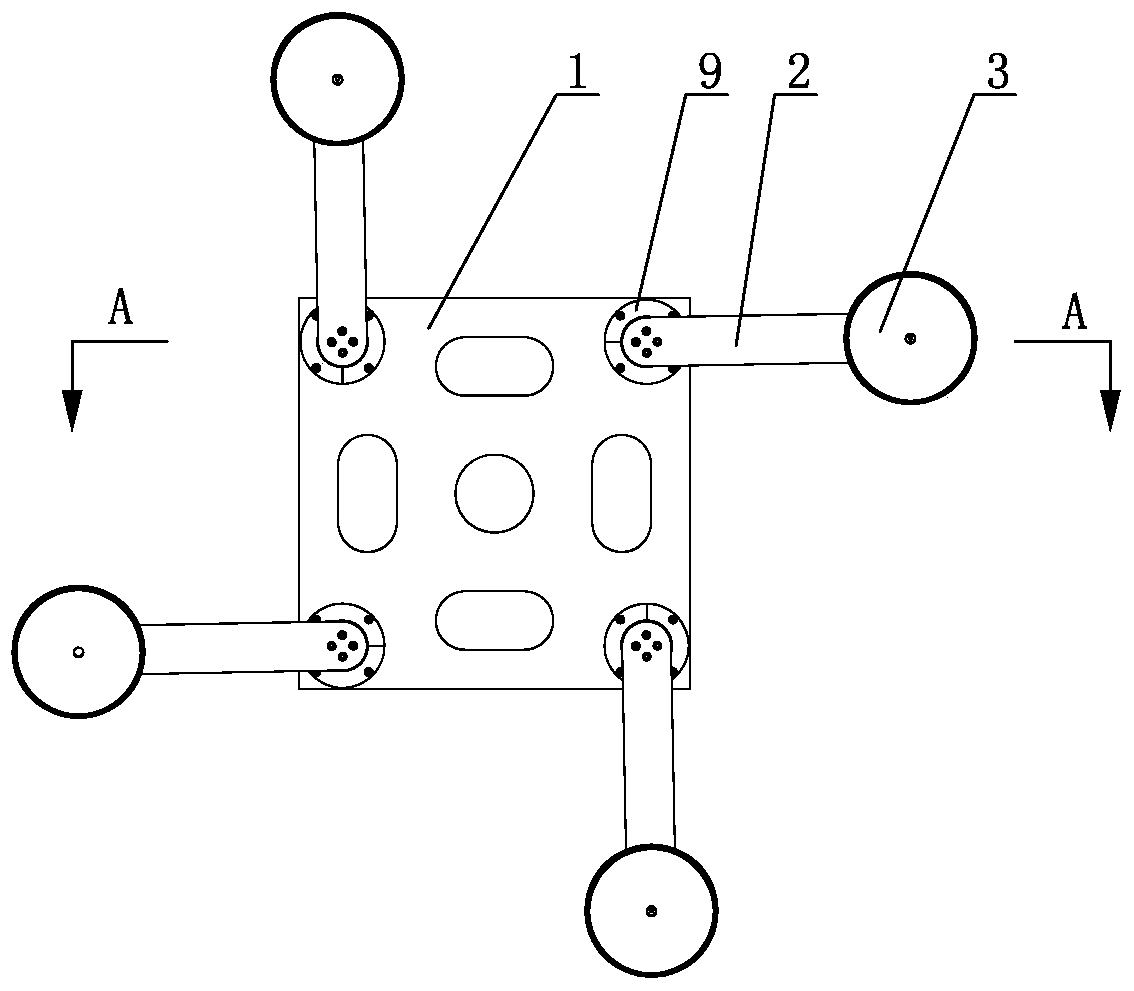

[0017] Such as Figure 1-5 As shown, it is an adaptive glass grabbing suction cup, which includes a mounting frame 1, a number of swing arms 2 are arranged on the lower side of the mounting frame 1, and each swing arm 2 is distributed around the outer circumference of the mounting frame 1 at intervals. The arm 2 is provided with several rotary drive mechanisms, one end of the swing arm 2 is in transmission connection with the corresponding rotary drive mechanism, and the other end of the swing arm 2 is provided with a suction cup 3 . The mounting frame 1 is rectangular, and there are four swing arms 2. The swing ends of each swing arm 2 are respectively arranged under the four corners of the mounting frame 1, and two adjacent swing arms 2 are perpendicular to each other. The rotary drive mechanism includes a servo motor 4, the output end of the servo motor 4 is connected to the input end of the speed reducer 5, the speed reducer 5 is vertically fixed on the mounting frame 1, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com