A kind of Schiffer base copper complex modified carbon nanotube and its preparation method and application

A carbon nanotube, copper complex technology, applied in the direction of carbon nanotubes, multi-walled carbon nanotubes, nanocarbons, etc., can solve the problems of complex operation, harsh reaction conditions, few types of chemical functional groups, etc., to reduce environmental pollution, The synthesis method is simple and feasible, and the effect of easy to gather into bundles is improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

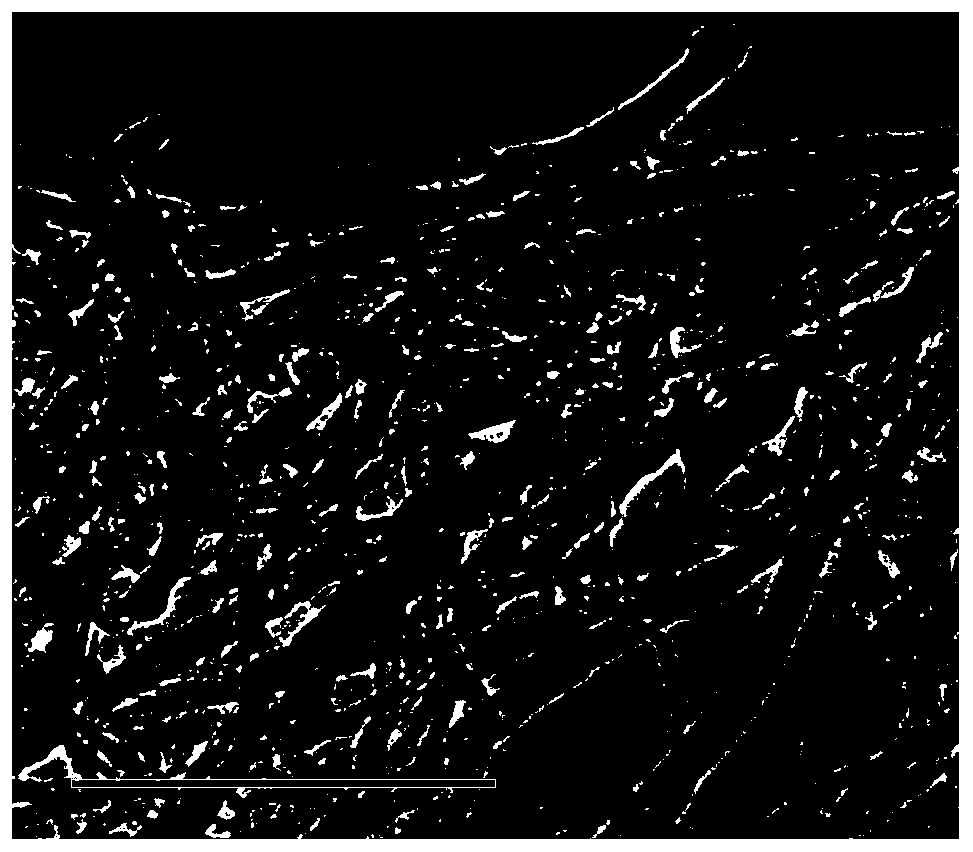

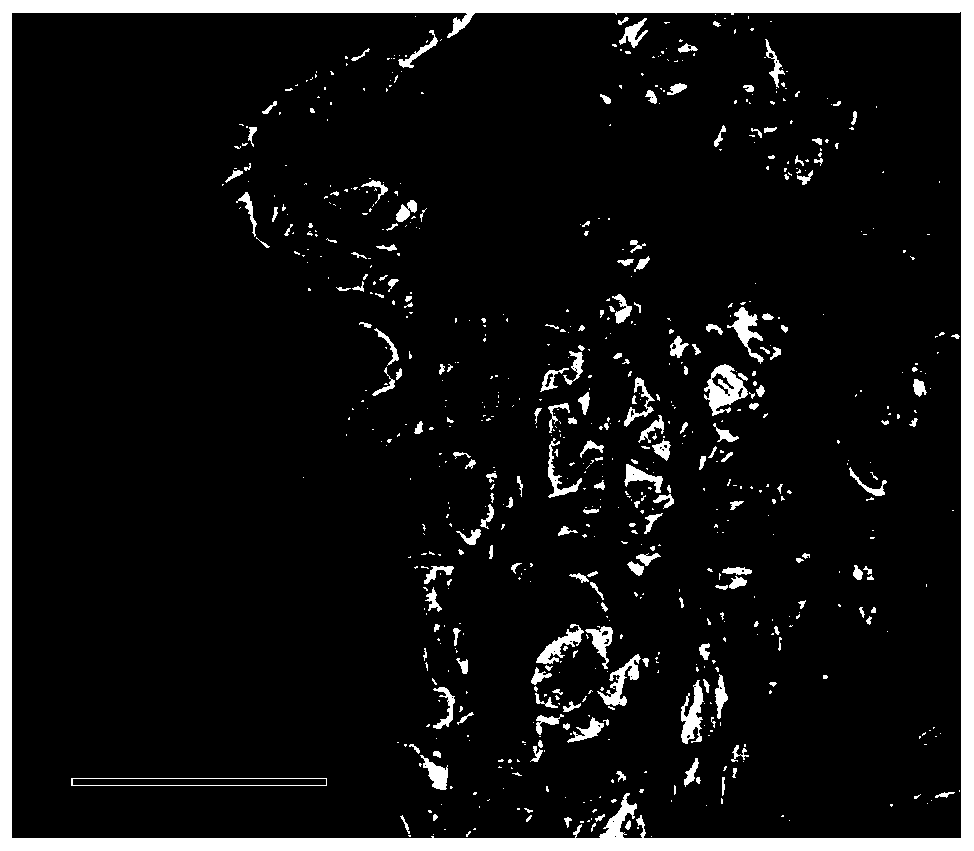

Image

Examples

Embodiment 1

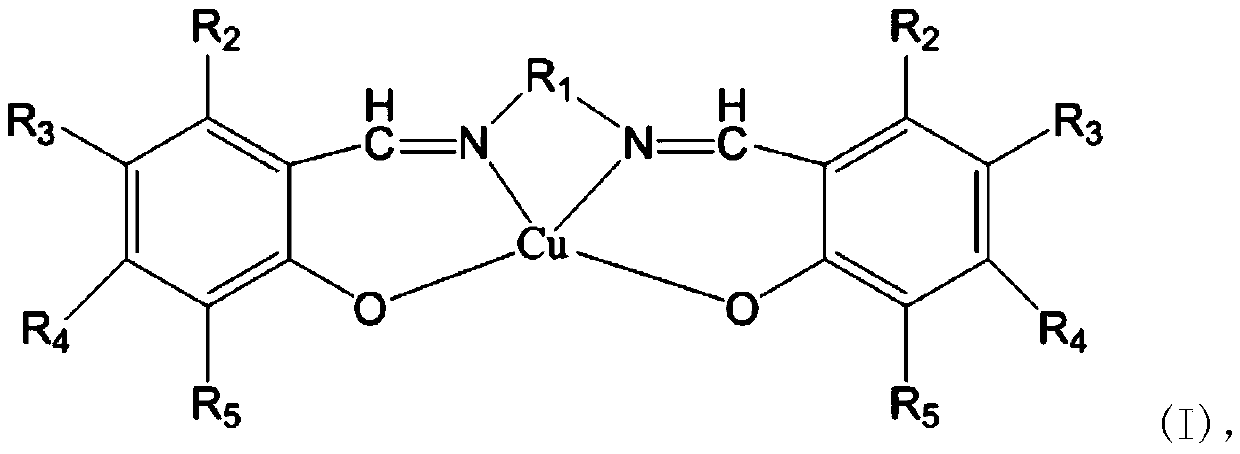

[0038] A Schiffer base copper complex modified multi-walled carbon nanotubes, the preparation method comprising the steps of:

[0039]1) Synthesis of Schiffer's base copper complex; mix 0.21mol salicylaldehyde and 60ml absolute ethanol, heat to reflux, slowly add the absolute ethanol solution of o-phenylenediamine dropwise, and control the dropwise addition within 1h, then Insulate and react at 80°C for 2 hours, cool, filter, recrystallize with ethanol, and dry in vacuum to obtain the Schiffer base compound;

[0040] Mix 30ml of absolute ethanol with 15.8g of the obtained Schiffer's base compound, heat to reflux, slowly add a saturated solution of copper acetate in absolute ethanol (containing 9.98g of copper acetate monohydrate), and control the dropwise addition within 2h, then Insulate and react at 85°C for 1 h, then cool and filter, wash with ethanol, and dry in vacuum to obtain the Schiffer's base Cu(II) complex;

[0041] 2) Mix the multi-walled carbon nanotubes in a mix...

Embodiment 2

[0046] A Schiffer base copper complex modified multi-walled carbon nanotubes, the preparation method comprising the steps of:

[0047] 1) Synthesis of Schiff's base copper complex; mix 0.21mol salicylaldehyde and 60ml absolute ethanol, heat to reflux, slowly add 1,6-hexamethylenediamine absolute ethanol solution dropwise, and control the dropwise addition within 1h After completion, heat preservation reaction at 80°C for 2 hours, cooling, filtration, recrystallization with ethanol, and vacuum drying to obtain the Schiff base compound;

[0048] Mix 16.2g of Schiff's base compound obtained by 30ml of absolute ethanol, heat to reflux, slowly add a saturated solution of copper acetate in absolute ethanol (containing 9.98g of copper acetate monohydrate), and control the dropwise addition within 2h, and then Insulated reaction at 85°C for 1 hour, then cooled and filtered, washed with ethanol, and vacuum-dried to obtain the Schiffer's base Cu(II) complex;

[0049] 2) Mix the carbon ...

Embodiment 3-4

[0054] The preparation method of the multi-walled carbon nanotubes modified by Schiffer's alkali copper complexes described in Examples 3-4 is roughly the same as in Example 1, except that the diamine compounds used are ethylenediamine and 1,2- Cyclohexanediamine.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com