Automatic turning and airing system for brewing grains

A technology of automatic turning and grain grain processing, applied in the preparation of alcoholic beverages, etc., can solve the problems of large drying area of grain grain grains, large workload of personnel, low drying efficiency, etc. effects of the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in conjunction with accompanying drawing and specific embodiment:

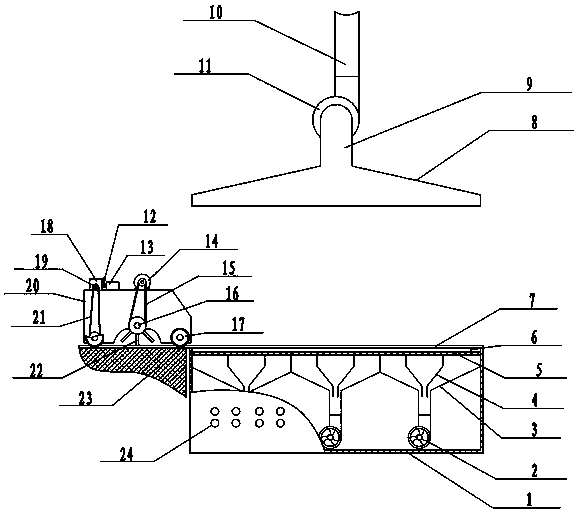

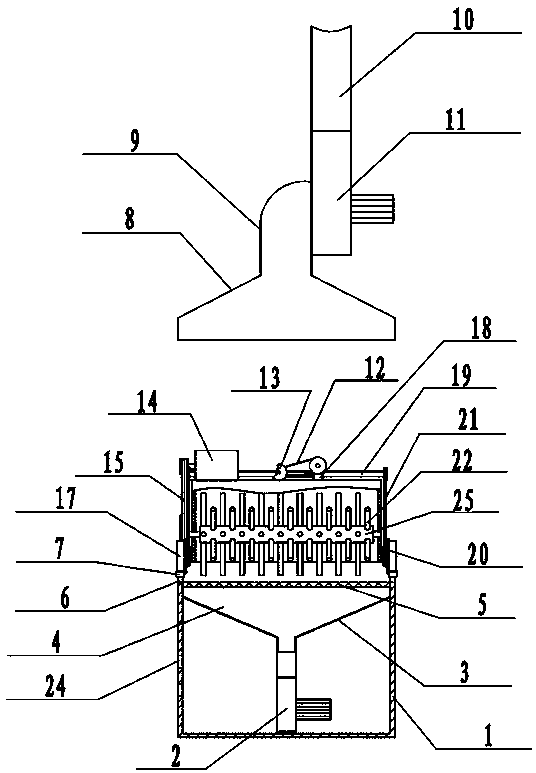

[0016] as attached figure 1 , figure 2 An automatic turning and airing system for brewing grain grains is shown, which includes a box body, a layer turning mechanism, a drying mechanism and a ventilation mechanism. The box body 1 is a rectangular box body, the upper part of the box body 1 is open, and the Evenly be provided with air inlet hole 24 on the front, box body 1 top is provided with baffle plate 6 symmetrically front and back, the top of baffle plate 6 is provided with guide rail 7, the right side of guide rail 7 is arranged on the top of baffle plate 6, the left side of guide rail 7 The side is arranged on the top of the base 23 on the left side of the casing 1, and the top of the guide rail 7 contacts with the runners 17 on both sides of the bottom of the turning mechanism; the turning mechanism is arranged on the upper left side outside the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com