Novel horizontal drying machine

A dryer and horizontal technology, applied in the field of new horizontal dryers, can solve the problems of uneven moisture content of the catalyst, unqualified product quality, and drying of the catalyst to less than 0.3%, so as to avoid uneven heating and improve quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

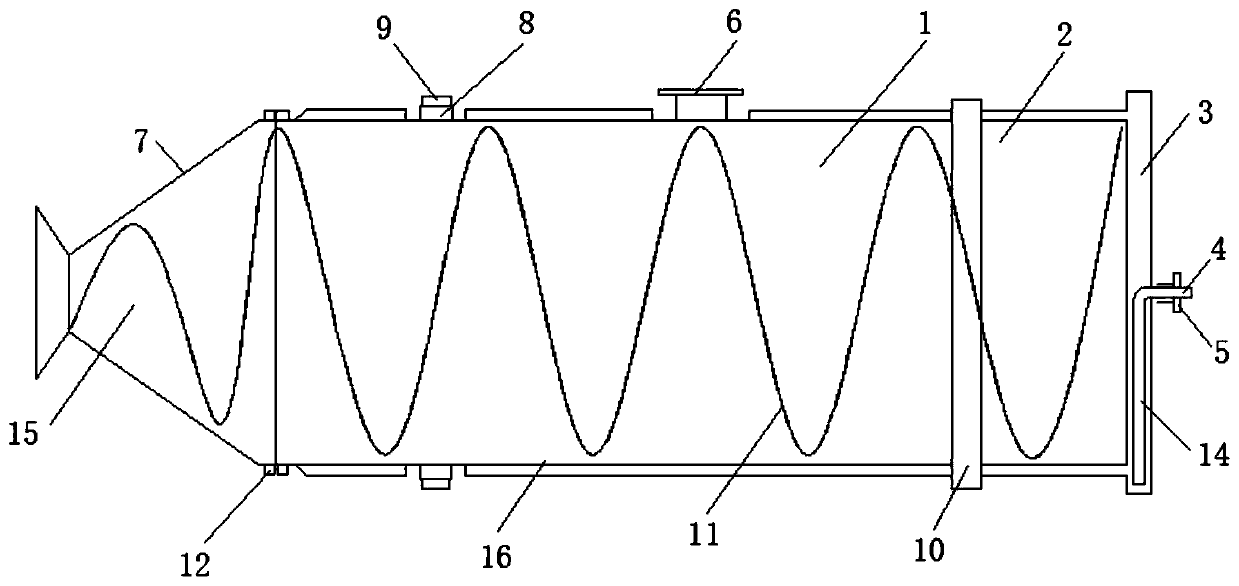

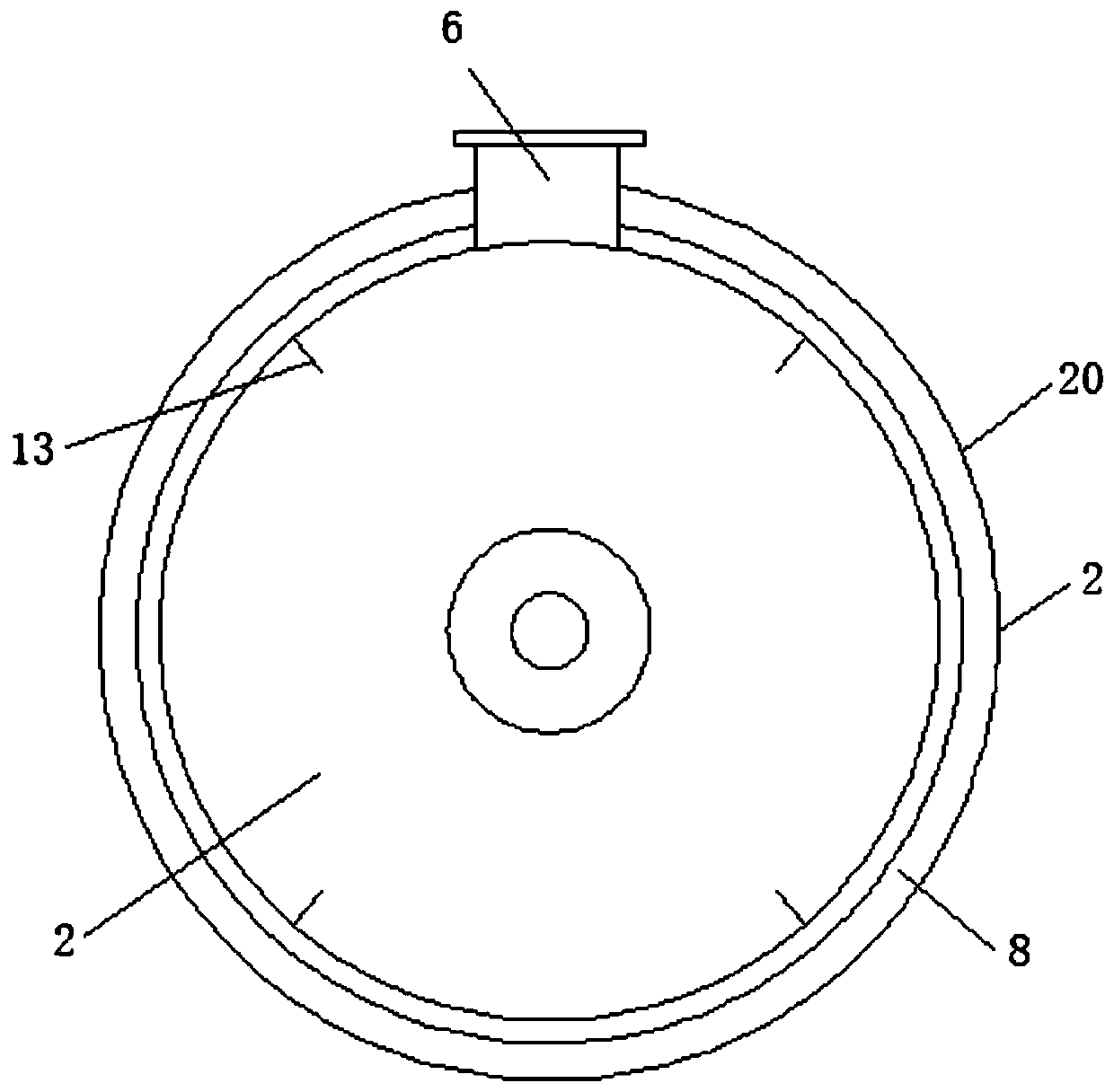

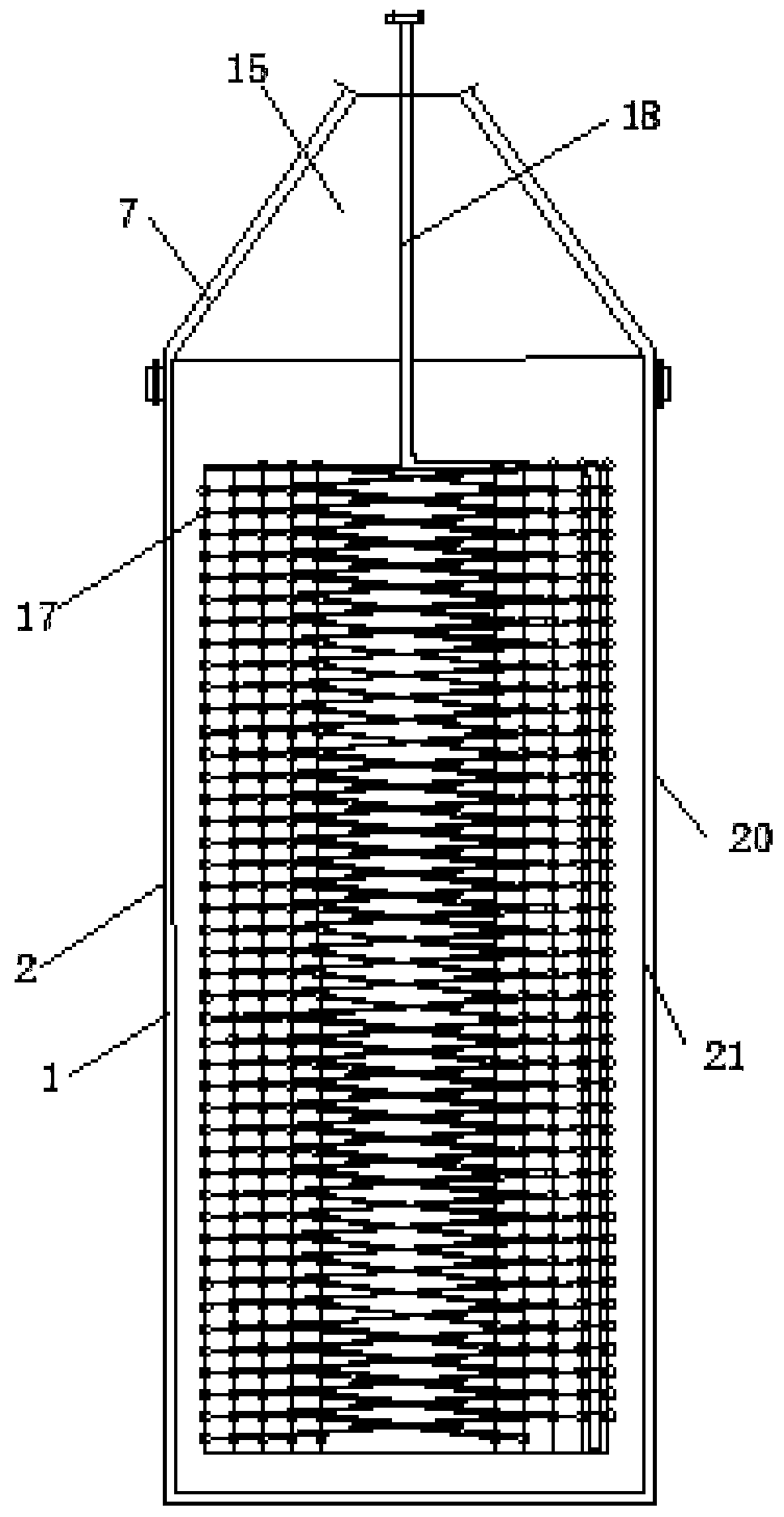

[0024] As a preferred embodiment of the present invention, the number of titanium plate spiral bands 11 is four groups, and both sides of the inner wall of the tank body 2 are evenly provided with multiple sets of spiral band fixing blocks 13, and the titanium plate spiral bands 11 are all passed through the spiral bands. The fixed block 13 is fixedly connected to the inside of the tank body 2, the side of the conical titanium plate tank 7 close to the tank body 2 communicates with the tank body 2, and the outer sides of the tank body 2 and the conical titanium plate tank 7 are provided with flanges 12 , and the tank body 2 is detachably connected to the conical titanium plate tank 7 through the mutual cooperation of the flange plate 12 and the fastening bolts.

[0025] This new type of horizontal dryer better fixes and connects the titanium plate spiral belt 11 through the spiral belt fixing block 13, which is convenient for fixing the titanium plate spiral belt 11 inside the ...

Embodiment 2

[0027] As a preferred embodiment of the present invention, the number of backing plates 8 is eight, and the first rolling belt 9 is fixedly connected with the tank body 2 through the backing plate 8, the number of the second rolling belts 10 is two groups, and the second The rolling belts 10 are all located on the side of the tank body 2 close to the cavity 3 .

[0028] This new type of horizontal dryer makes the fixing effect of the first rolling belt 9 and the tank body 2 better through the backing plate 8, and facilitates the tank body 2 in the rolling process by using the first rolling belt 9 and the second rolling belt 10 Play the role of support (the tank body 2 rolls under the action of external force, and the specific components and structure of rolling belong to the prior art, which will not be described in detail here), thereby improving the stability.

[0029] Example 2

[0030] As a preferred embodiment of the present invention, the material of the straight sectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com