Folding combined type temporary bridge device

A combination and bridge technology, applied to bridges, bridge parts, bridge forms, etc., can solve problems such as poor versatility and complex structure, and achieve the effects of easy transportation, good structural strength, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

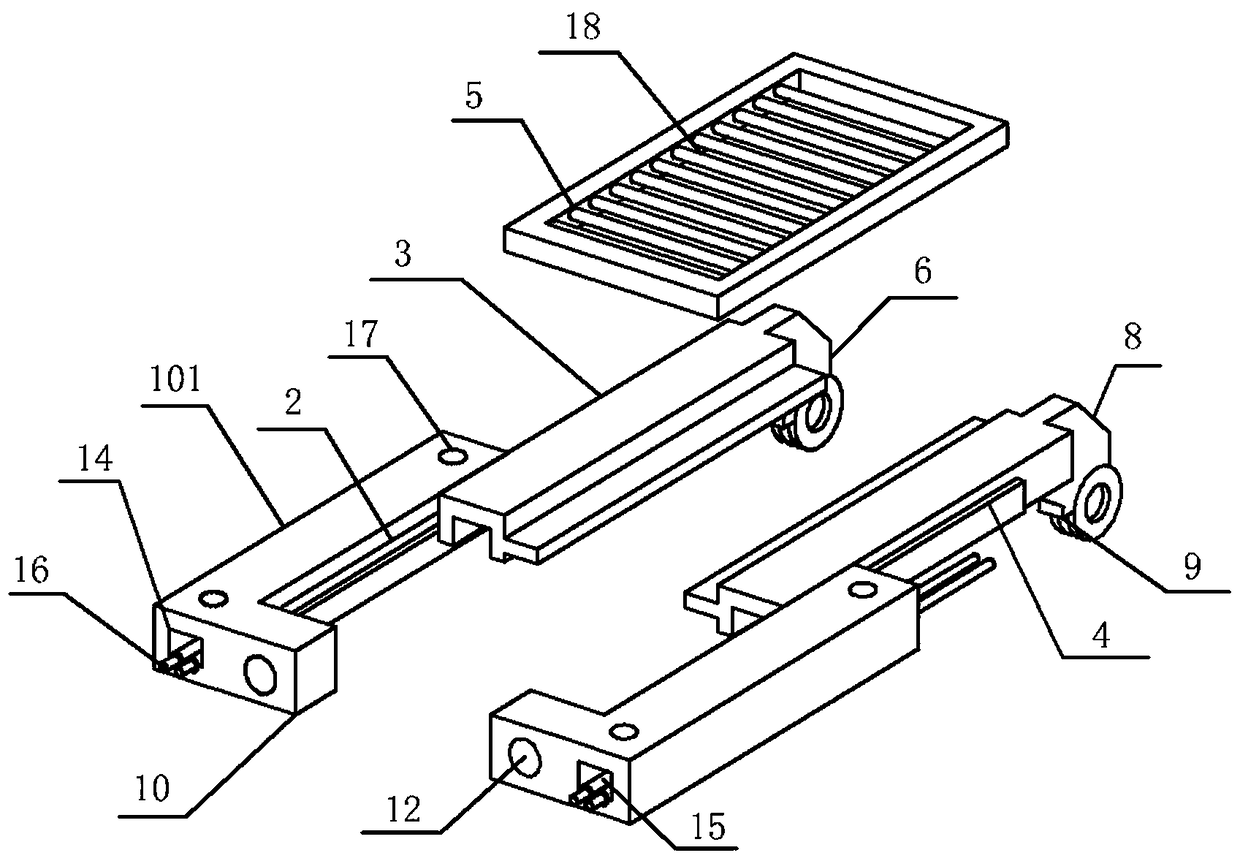

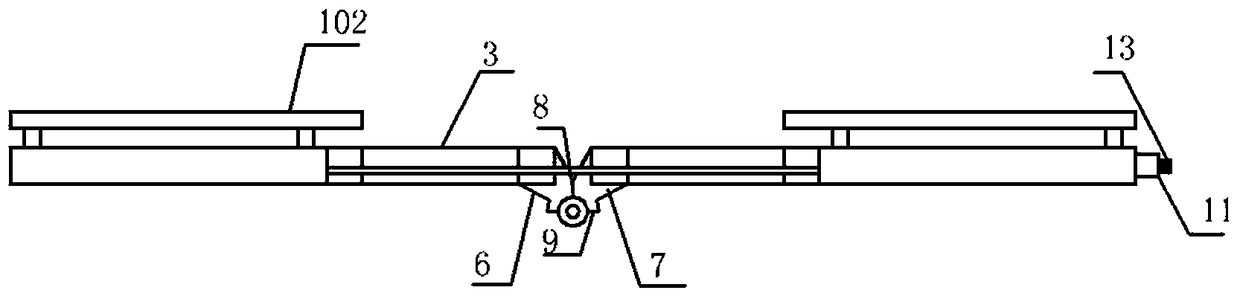

[0025] A kind of foldable and combined temporary bridge device of the present embodiment, such as figure 1 , figure 2 , image 3 with Figure 4 As shown, at least two folded bridge assemblies are included, and a whole bridge structure is formed by splicing the folded bridge assemblies with each other. Frame 101 and the fixed plate 102 structure that is arranged on the bottom frame 101; The bottom frame 101 comprises two mutually parallel square steel structures and two mutually parallel channel steels 3, and each square steel structure inside is provided with A slide rail 2 parallel to the long side of the square; the channel steel 3 is slidingly connected with the square steel through a T-shaped convex strip 4 that is arranged on one side and embedded in the slide rail 2; The fixed plate 102 is parallel to the mesh plate 5; the two groups of channel steel 3 on two adjacent folded plates 1 are hinged so that the two folded plates 1 can be rotated by 90° for folding.

Embodiment 2

[0027] This embodiment is further defined on the basis of the above-mentioned embodiments, the channel steel 3 is provided with an ear seat 6 at the hinged end, and the channel steel 3 corresponding to the adjacent folded plate 1 is provided with a hinge joint with the ear seat 6. The single-ear insert 7 is inserted into the corresponding ear seat 6 and inserted into the rotating shaft to form a hinged relationship; the ear seat 6 and the single-ear insert 7 are provided with two foldable parts for limiting mutual hinge The parallel flange 8 that continues to rotate upward when the plate 1 is completely opened horizontally, and the ear seat 6 and the single ear plug 7 are also provided with a semicircle that is used to limit the two hinged folding plates 1 to continue to rotate toward each other when they are fully parallel folded flange9. Other parts of this embodiment are the same as those of the foregoing embodiment, and will not be repeated here.

Embodiment 3

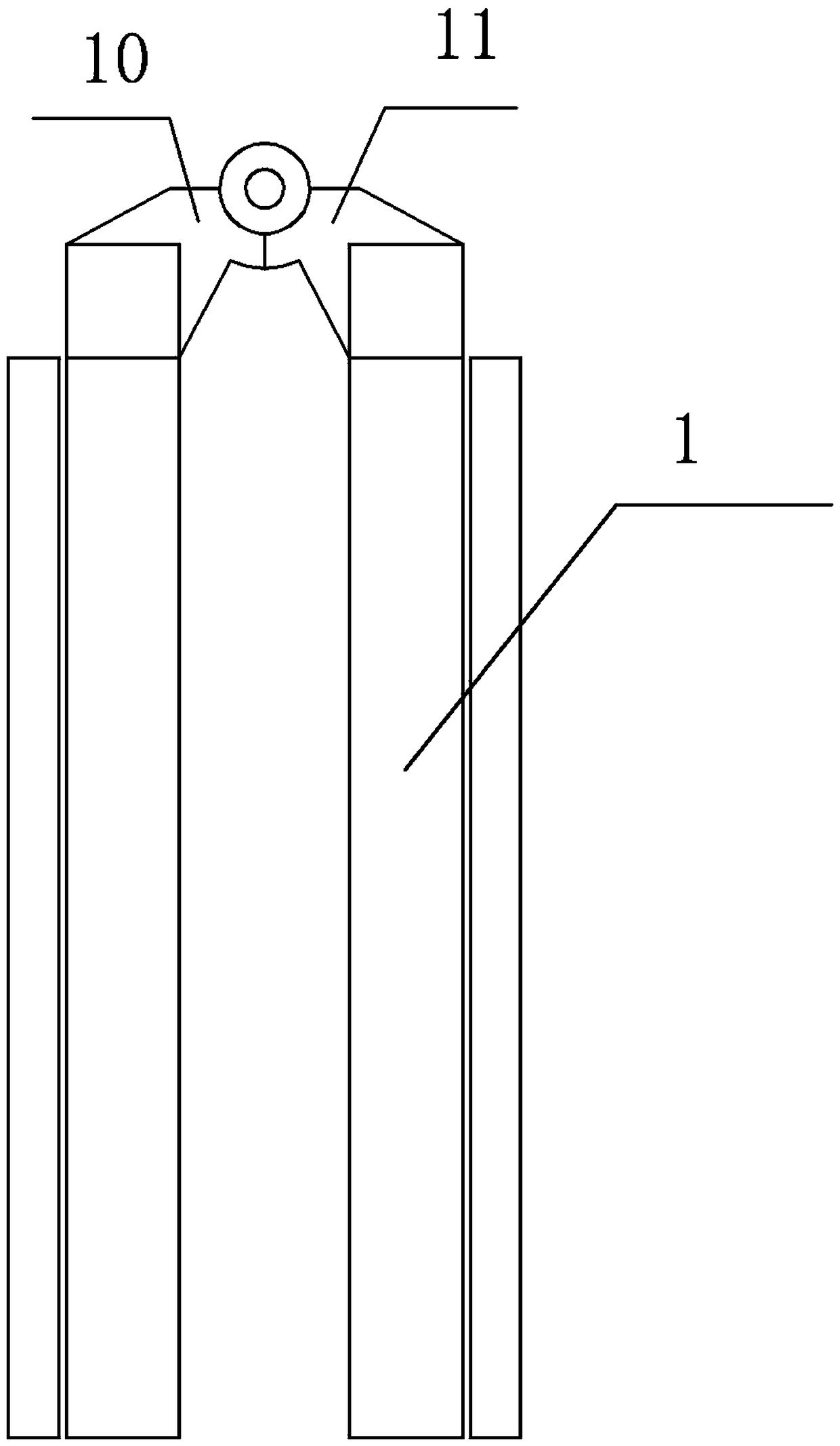

[0029] This embodiment is further defined on the basis of the above embodiments, the square steel is an L-shaped structure, the side of the square steel on the same folded bridge assembly away from the hinge is provided with an insert perpendicular to the long side of the square steel The socket 10, on the other side of the same folding bridge assembly and also away from the direction steel end of the hinged end, is provided with a socket block 11 that is mated with the socket block 10, and the end surface of the socket 10 is provided with Perpendicular to the round through hole 12 on the end surface, the plug block 11 is provided with a screw rod 13 inserted into and passed through the corresponding round through hole 12 and a nut is provided at the end to cooperate and fix it. Other parts of this embodiment are the same as those of the foregoing embodiment, and will not be repeated here.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap