Combined type steel plate pile enclosure structure and construction method thereof

A technology for enclosure structures and steel sheet piles, which is applied in foundation structure engineering, sheet pile walls, buildings, etc., can solve the problems of difficult piling, low bending rigidity, and low accuracy, and achieve low piling difficulty and high bending rigidity. High, strong connection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

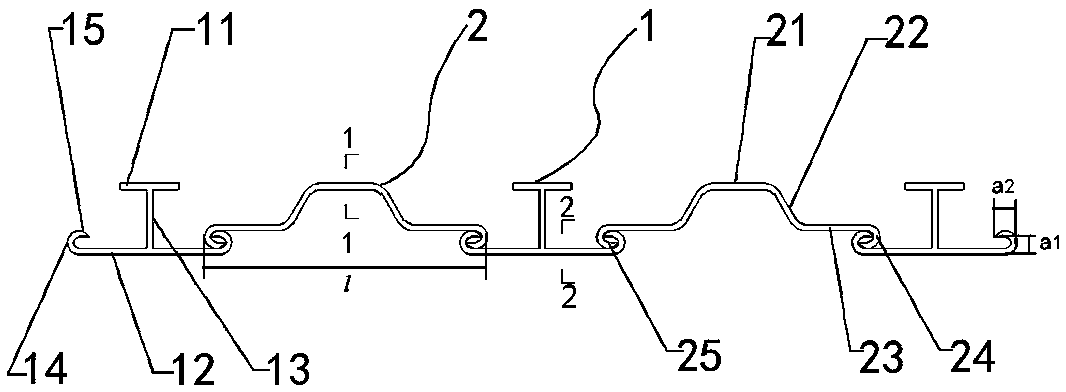

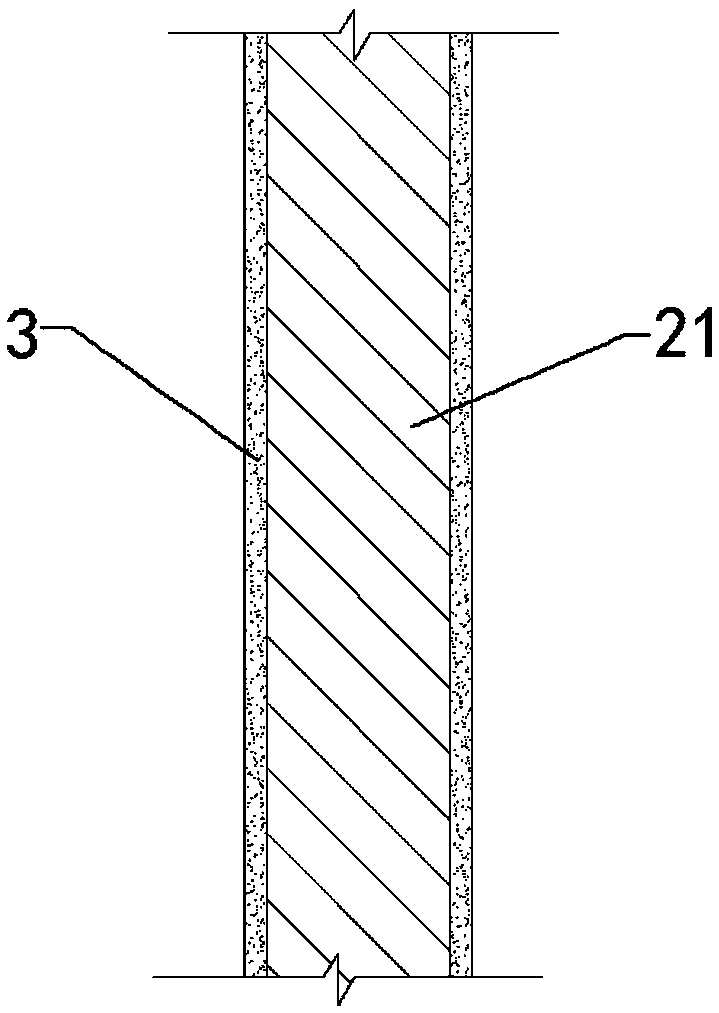

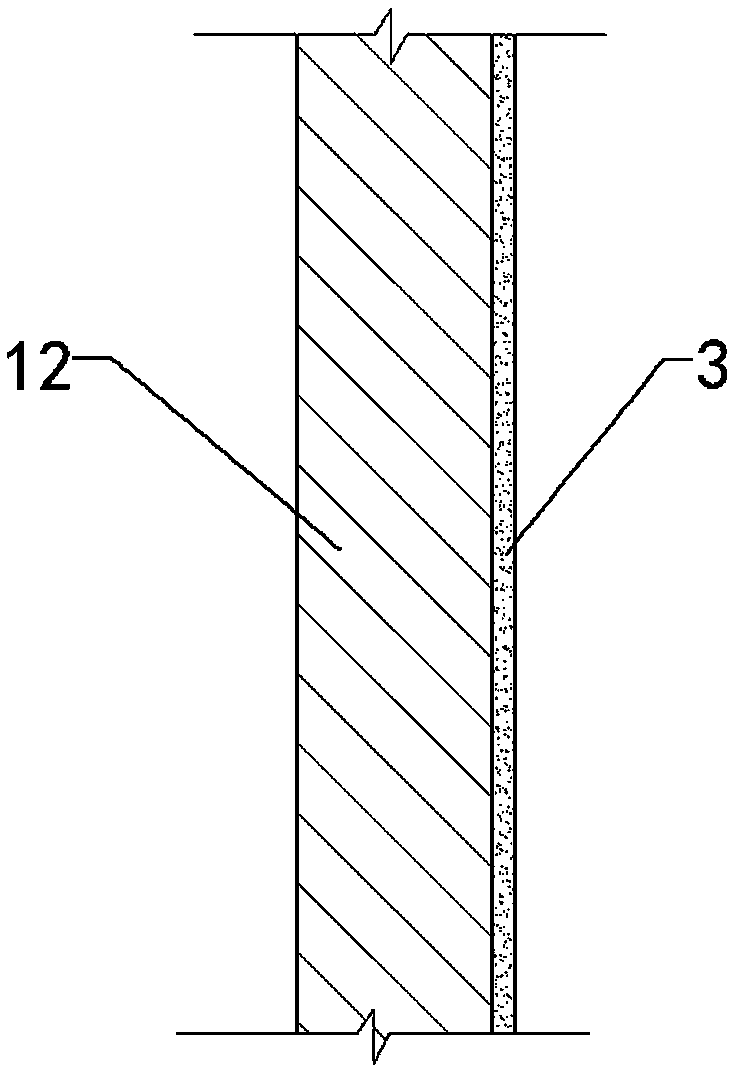

[0038] Such as figure 1 As shown, the combined steel sheet pile enclosure structure of the present invention includes H-shaped steel 1 and hat-shaped steel plate 2 arranged alternately and connected in parallel;

[0039] The H-shaped steel 1 includes a web 13, a short flange 11 and a long flange 12 perpendicular to the web 13, and the width of the short flange 11 is 1 / 3-1 / 2 of the width of the long flange 12 , the web 13 is set at the same width as the short flange plate 11, and the edges on both sides of the long flange plate 12 are vertically bent and extended to the side close to the short flange plate 11 respectively to form a first fastening portion 14, and the long flange plate 12 and the The first fastening part 14 is connected through a smooth transition through a circular arc; the edge of the first fastening part 14 extends horizontally inward to form a first locking part 15, and the first locking part 15 and the first fastening part 14 transition smoothly through a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com