Material level detection device for ball grinding mill

A technology of material level detection and ball mill, applied in liquid level indicators for physical variable measurement, grain processing, etc., can solve the problems of limited life, large battery size, difficulty in regular maintenance and replacement, etc. The effect of discontinuous detection of ball mill material level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

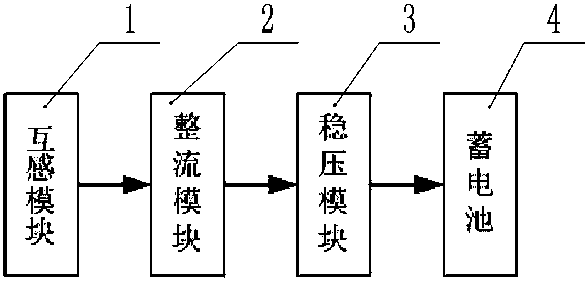

[0017] Such as figure 1 As shown, a ball mill material level detection device of the present invention includes a material level detection sensor, and also includes a mutual induction module 1, a rectification module 2, a voltage stabilizing module 3 and a battery 4, and the output terminal of the mutual induction module 1 is connected with the rectification module 2, and the rectification module The module 2 is connected to the voltage stabilizing module 3, and the voltage stabilizing module 3 is connected to the storage battery 4;

[0018] The material level detection sensor uses a vibration sensor and an acceleration sensor. The material level detection sensor is connected to the preamplifier to amplify and filter the signal to improve the signal-to-noise ratio of the signal and make the signal amplitude meet the range of analog-to-digital conversion. Finally The final digital signal is obtained through analog-to-digital conversion processing.

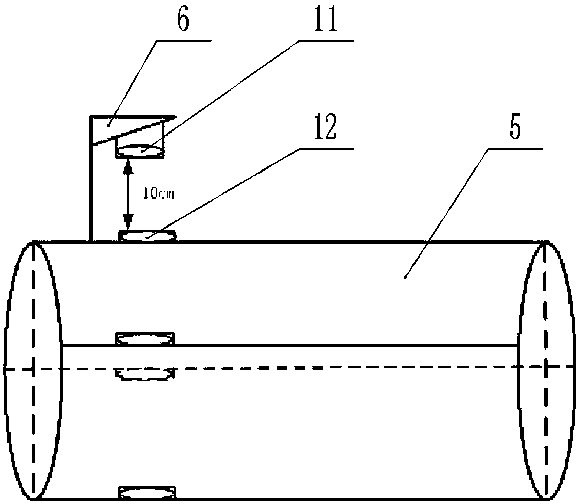

[0019] The mutual inductanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com