Compact-type thermoelectric power generation device

A thermoelectric power generation, compact technology, used in generators/motors, electrical components, etc., can solve the problems of difficult heat exchange enhancement at the hot end of thermoelectric devices, limiting the power increase of thermoelectric generators, and limited installation of thermoelectric devices. Improve overall thermoelectric performance and energy utilization, flexible configuration, and improve service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0033] The invention provides a compact thermoelectric power generation device aiming at the prior art.

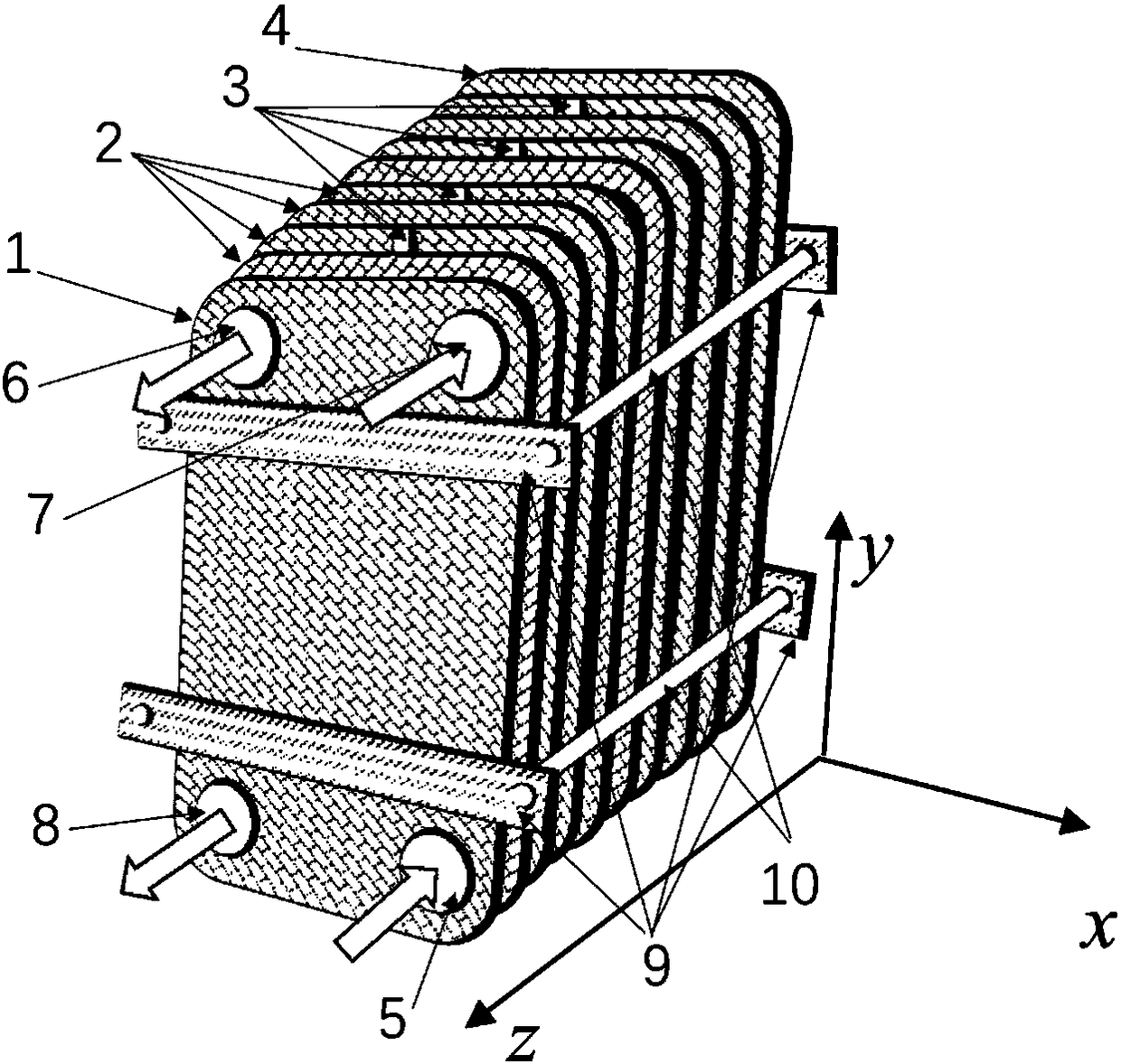

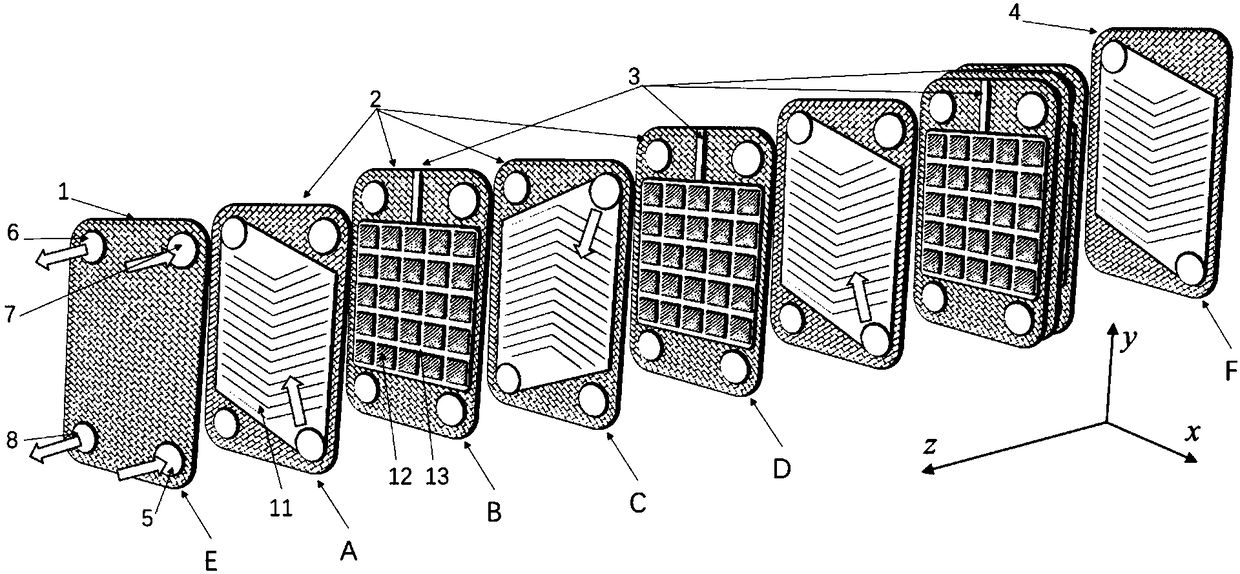

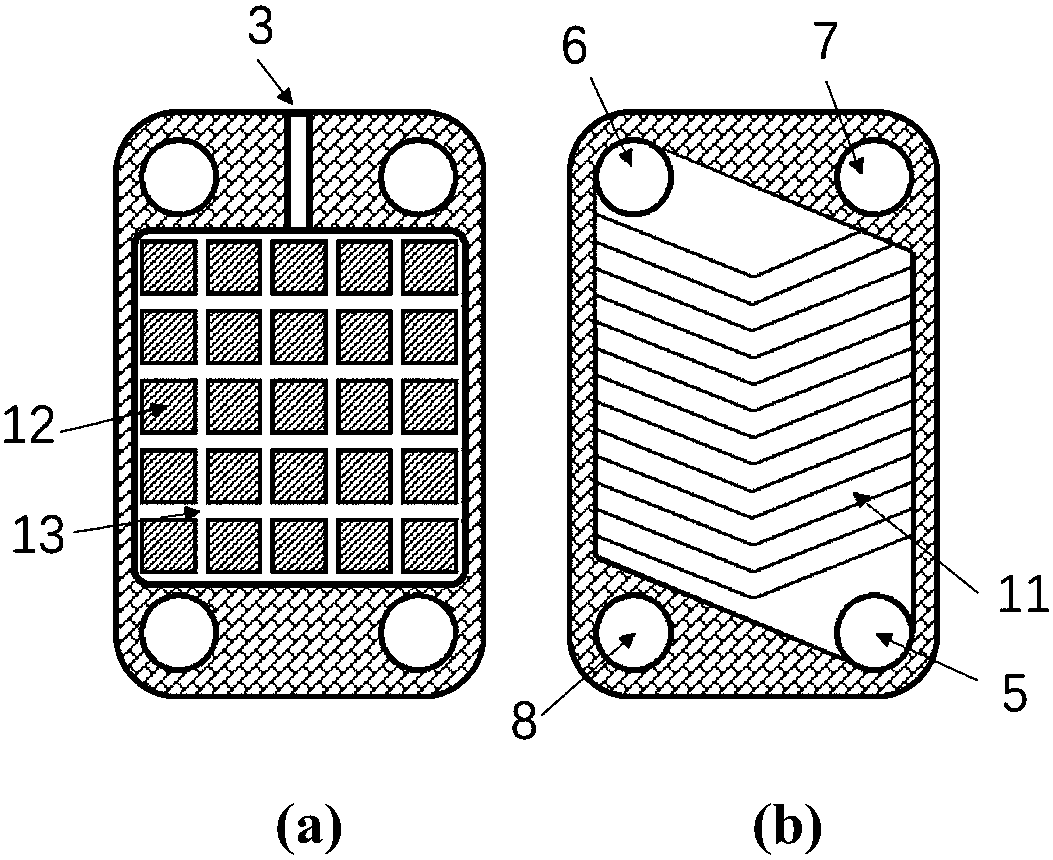

[0034] Such as figure 1As shown, the device includes a compact thermoelectric power generation module, a thermal fluid heater 16, a cold fluid cooler 17, a thermal fluid circulation pump 14, a cold fluid circulation pump 15, cold / hot fluid pipelines, etc., wherein the compact thermoelectric power generation The module is composed of front cover deflector 1, A-B-C-D series deflector combination 2, and rear end cover deflector 4. The compact thermoelectric power generation module has circulation channels for cold fluid and hot fluid, among which the cold fluid The inlet passage 5, the cold fluid outlet passage 6 and the cold fluid pipeline, the cold f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com