High-flexibility seat used for automobile

A high flexibility, automotive technology, applied in movable seats, seat heating/ventilation devices, thigh cushions, etc., can solve the problems of low functionality, improve functionality, improve autonomy, and meet different heating requirements effect of demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

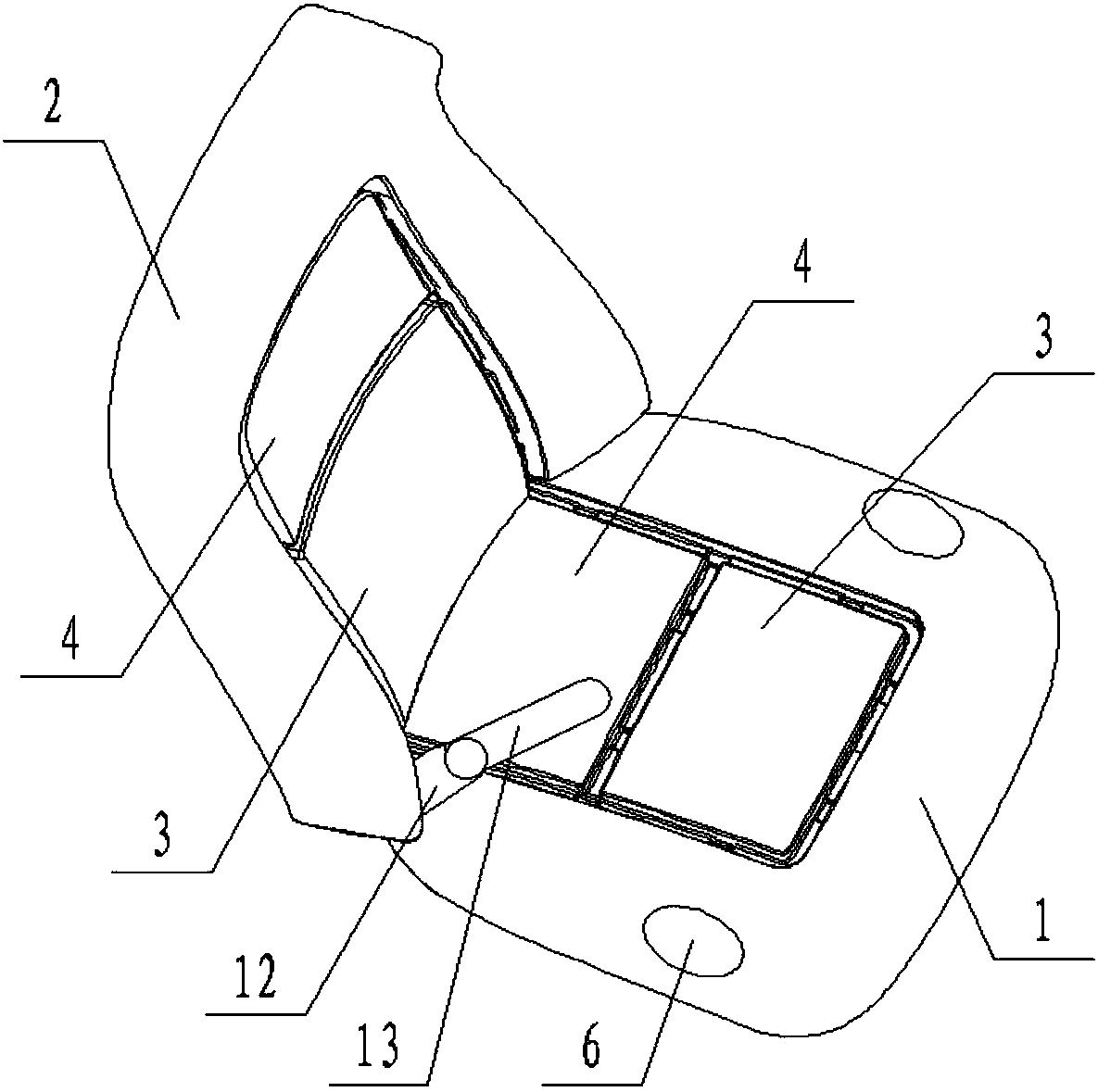

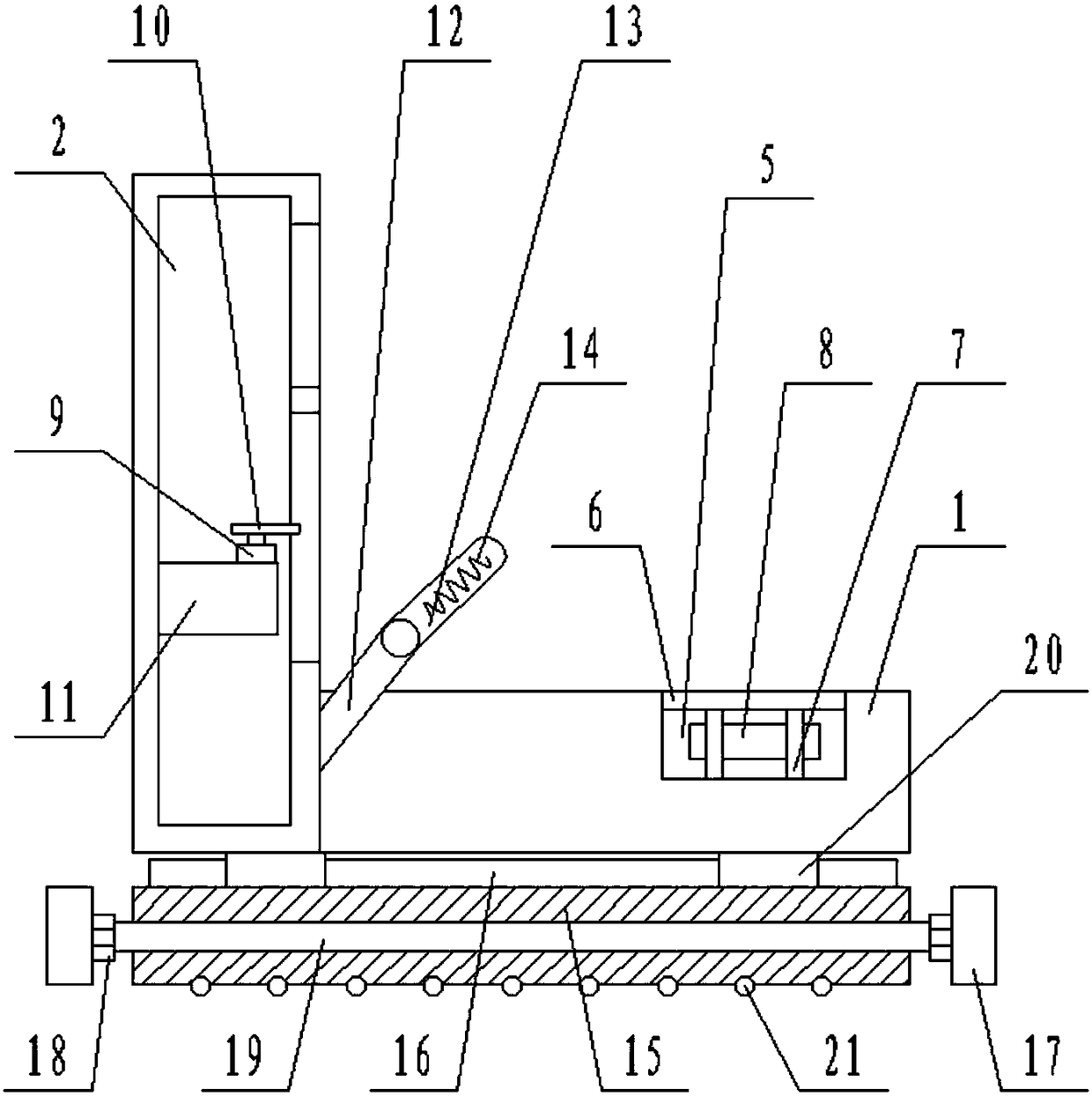

[0027] Such as figure 1 and figure 2 The shown high-flexibility chair for automobiles comprises a cushion 1 and a backrest 2 connected to each other, and the surface of the cushion 1 includes a first covering layer 3 and a second covering layer 4 arranged from front to back, and the backrest 2 The surface includes a first covering layer 3 and a second covering layer 4 arranged from top to bottom, the first covering layer 3 is leather, and the second covering layer 4 is an elastic material; the seat cushion 1 Both sides of the first covering layer 3 are provided with grooves 5, and the open end of the groove 5 is laid with a rubber layer 6, and a bracket 7 is arranged in the groove 5, and one end of the bracket 7 is connected with the bottom of the groove 5, and the other end is connected with the rubber layer. 6 connection, the vibration motor 8 is fixed on the bracket 7; the side of the backrest 2 is provided with a connecting part 12 protruding to the front of the backrest...

Embodiment 2

[0029] Such as figure 1 and figure 2In the shown high-flexibility chair for automobiles, on the basis of Embodiment 1, the bottom of the seat cushion 1 is provided with a slider 20 that matches the slide rail 16 . A plurality of rollers 21 are evenly distributed around the bottom of the base 15 . The elastic material is a sponge material. The motor 9 is a variable frequency motor. The heat conductor 13 is a hollow aluminum alloy. The electric heating device 14 is a heating resistance wire. A mounting block 11 is fixed inside the backrest 2 , and the motor 9 is arranged on the mounting block 11 . The cam 10 is an eccentric wheel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com