Pickup truck front bumper assembly

A front bumper and bumper technology, which is applied to bumpers, vehicle safety arrangements, radiators, etc., can solve problems such as damage to the interior components of the car, insufficient driving safety, deformation of the front frame, etc., so as to improve driving safety, Simple structure and the effect of reducing wind resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical solution of the present invention clearer, the present invention will be further described below in conjunction with the accompanying drawings. Any solution obtained by equivalent replacement and conventional reasoning of the technical features of the technical solution of the present invention falls within the protection scope of the present invention.

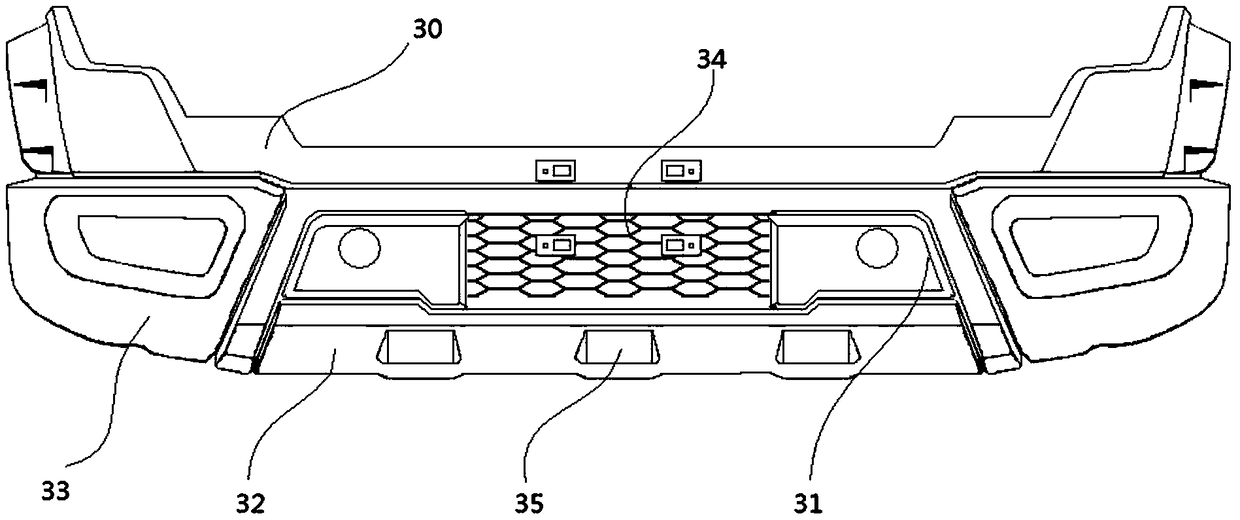

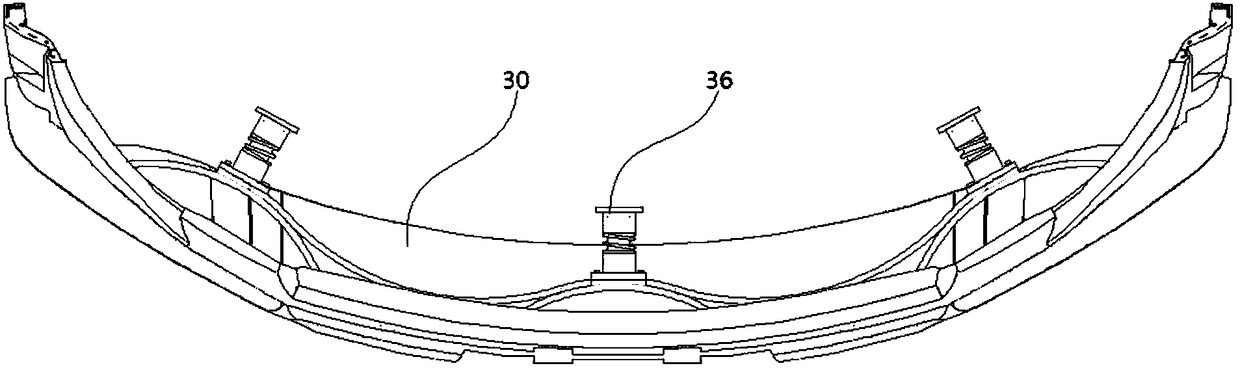

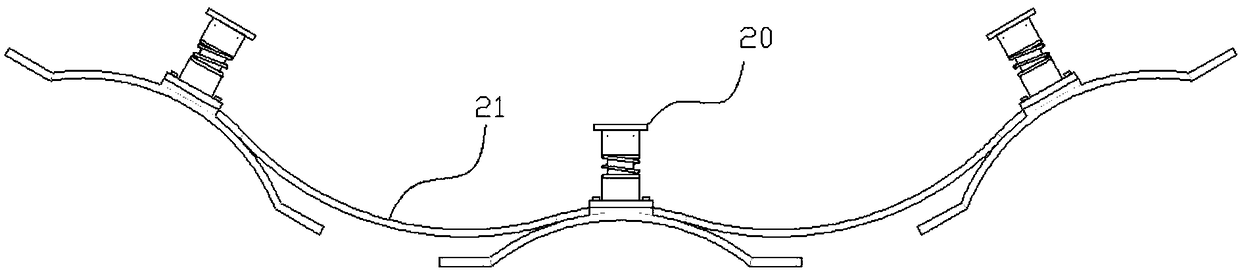

[0024] A pickup front bumper assembly as shown in the figure includes a bumper main body 30, which is characterized in that the bumper main body 30 is provided with a bumper energy-absorbing plate 31, a windproof plate 32, and a front fog lamp decorative plate 33 and the front grille 34, the bumper energy-absorbing plate 31 is covered and installed on the front surface of the bumper body 30, and is riveted and fixed with the bumper body 30, and the windproof plate 32 is fixedly arranged on the lower side of the bumper body 30. There is a windproof edge 35 protruding from the outer surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com