Unpowered water wave pump

A water wave and power technology, applied in the field of non-powered water wave pumps, can solve the problems of continuous high-pressure water supply, low water wheel efficiency, and low efficiency, and achieve the effects of small vibration, small footprint, and non-destructive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

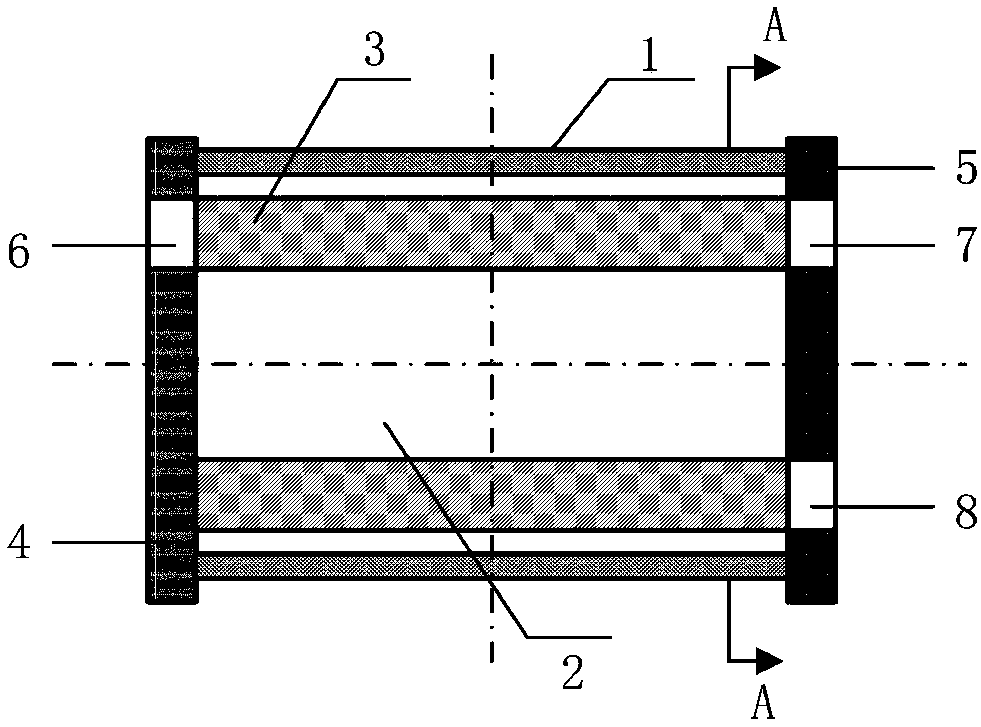

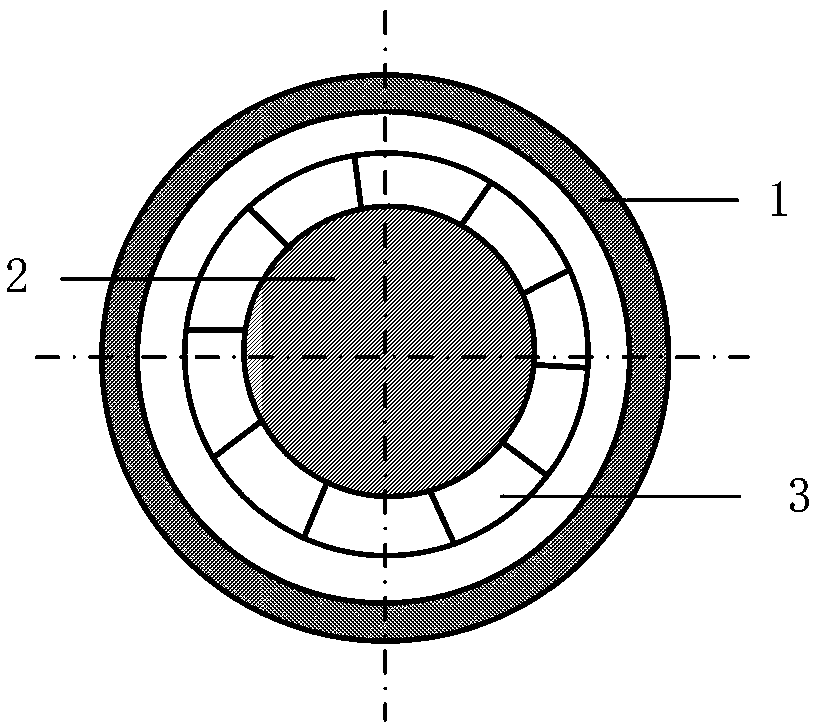

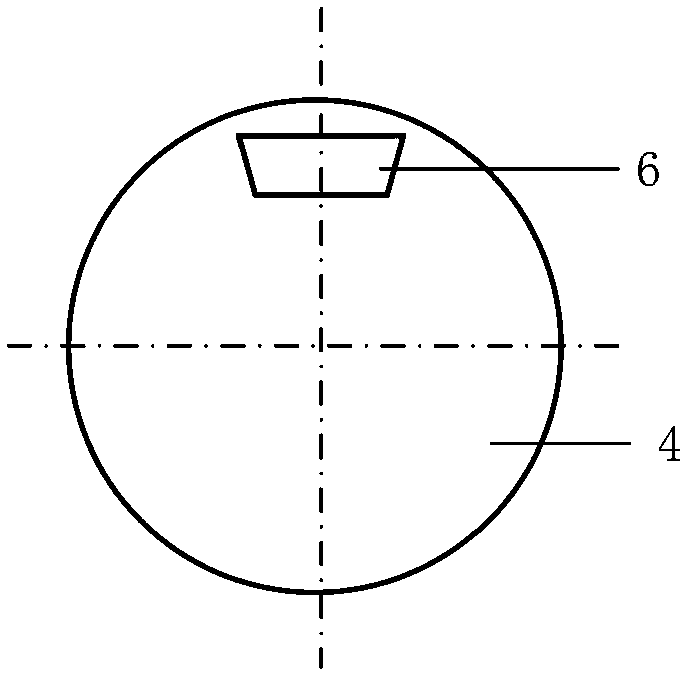

[0021] The unpowered water wave pump in the present embodiment, as figure 1 , figure 2 , image 3 and Figure 4 , including an outer cylinder 1, an inner cylinder 2 is provided inside the outer cylinder 1, the outer cylinder 1 and the inner cylinder 2 are coaxially placed, and there are multiple grooved impellers 3 between the outer cylinder 1 and the inner cylinder 2, and the grooved impellers 3 are Evenly distributed on the circumference, one end of the outer cylinder 1 and the inner cylinder 2 is connected with the front end cover 4 , and the other end is connected with the rear end cover 5 . There is a medium-pressure water inlet 6 on the front-end cover 4, and the medium-pressure water inlet 6 is on the upper edge of the front-end cover 4. The medium-pressure water inlet 6 and the front-end cover 4 have an inclination angle α, and the range of the inclination angle α is 5° to 10° There is a high-pressure water outlet 7 and a low-pressure water outlet 8 on the rear end...

Embodiment 2

[0023] The unpowered water wave pump in this embodiment includes an outer cylinder 1, an inner cylinder 2 is arranged inside the outer cylinder 1, the outer cylinder 1 and the inner cylinder 2 are placed coaxially, and there are multiple grooves between the outer cylinder 1 and the inner cylinder 2 The grid impeller 3 and the grooved grid impeller 3 are evenly distributed on the circumference. One end of the outer cylinder 1 and the inner cylinder 2 is connected to the front end cover 4 , and the other end is connected to the rear end cover 5 . There is a medium pressure water inlet 6 and a low pressure water outlet 8 on the front end cover 4, the medium pressure water inlet 6 is on the lower edge of the front end cover 4, the low pressure water outlet 8 is on the upper edge of the front end cover 4, the medium pressure water inlet 6 and the low pressure water outlet The water outlets 8 all have an inclination angle α with the front end cover 4, and the range of the inclination...

Embodiment 3

[0025] The unpowered water wave pump in this embodiment includes an outer cylinder 1, an inner cylinder 2 is arranged inside the outer cylinder 1, the outer cylinder 1 and the inner cylinder 2 are placed coaxially, and there are multiple grooves between the outer cylinder 1 and the inner cylinder 2 The grid impeller 3 and the grooved grid impeller 3 are evenly distributed on the circumference. One end of the outer cylinder 1 and the inner cylinder 2 is connected to the front end cover 4 , and the other end is connected to the rear end cover 5 . There is a medium-pressure water inlet 6 and a high-pressure water outlet 7 on the front end cover 4, the medium-pressure water inlet 6 is on the lower edge of the front-end cover 4, the high-pressure water outlet 7 is on the upper edge of the front-end cover 4, the medium-pressure water inlet 6 and the high-pressure The water outlet 7 has an inclination angle α with the front end cover 4, and the range of the inclination angle α is 5-10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com