Transmission system of five-gear mechanical automatic transmission

An automatic transmission, mechanical technology, applied in the direction of mechanical equipment, vehicle gearboxes, transmissions, etc., can solve problems such as power interruption, complex control technology, poor shift quality, etc., to reduce power interruption time and improve system stability , Improve the effect of shifting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

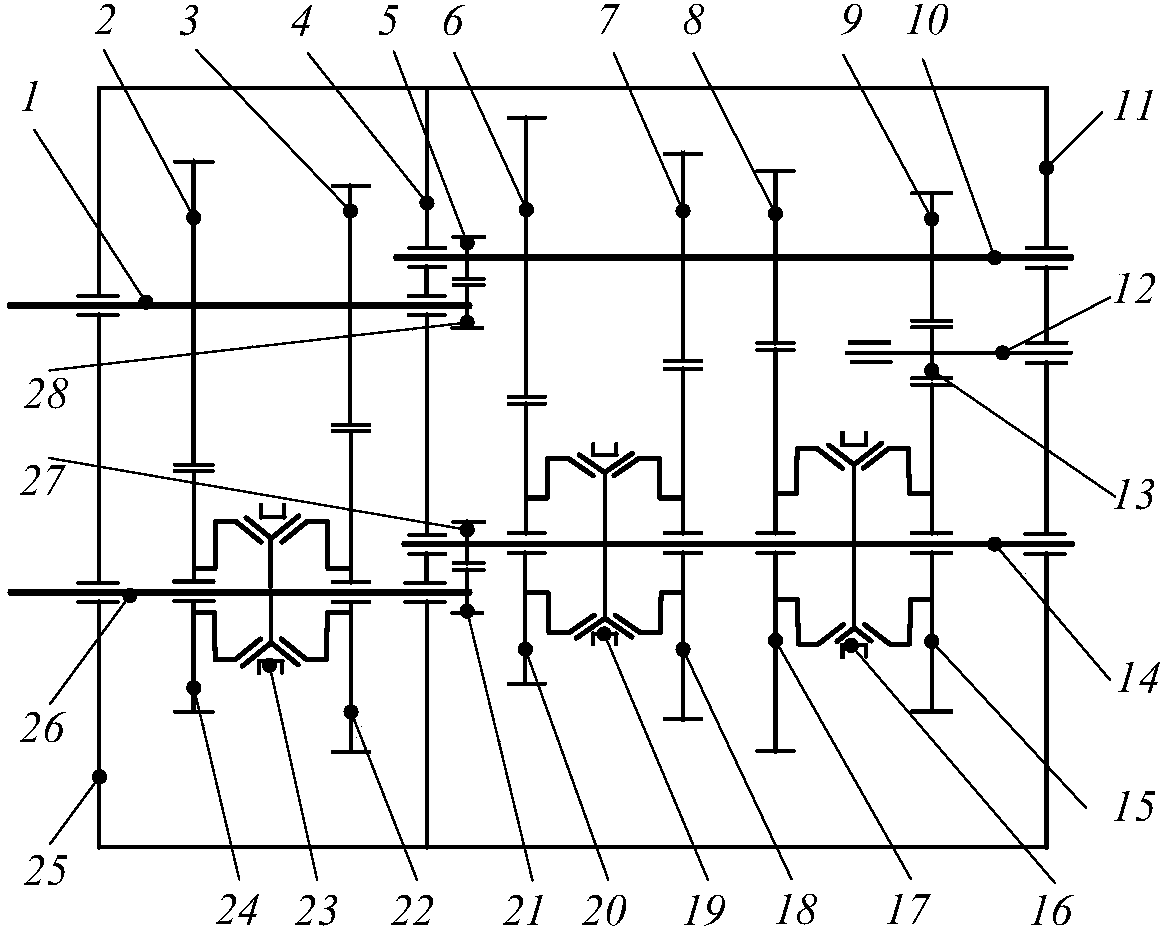

[0017] Embodiment 1 A description of the structure of a transmission system of a five-speed mechanical automatic transmission

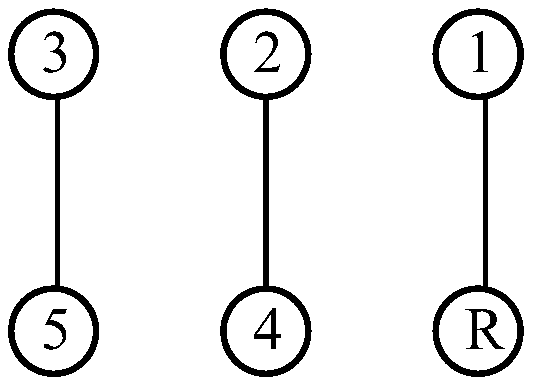

[0018] Such as figure 1 , figure 2 As shown, a five-speed mechanical automatic transmission transmission system, the transmission includes a left box body 25, a right box body 11, a support body 4, an input shaft 1, an output shaft 26, an intermediate shaft 10, an intermediate shaft 14, an inverted Gear shaft 12, first gear driving gear 8, second gear driving gear 7, third gear driving gear 3, fourth gear driving gear 6, fifth gear driving gear 2, reverse gear driving gear 9, first gear passive gear 17, second gear passive gear 18. Third gear passive gear 22, fourth gear passive gear 20, fifth gear passive gear 24, reverse gear passive gear 15, reverse gear intermediate gear 13, input shaft constant meshing gear 28, middle one shaft constant meshing gear 5, output shaft constant Engagement gear 21, intermediate two-shaft constant mesh gear 27, firs...

Embodiment 2

[0027] Embodiment 2 A five-speed mechanical automatic transmission transmission system power transmission route and working principle

[0028] Neutral. The power is transmitted to the input shaft of the transmission system, and the transmission shift actuator controls each synchronizer not to mesh with any gear driving gear, the power cannot be transmitted to the output shaft of the transmission system, and the transmission is in the neutral position.

[0029] one block. The gear shift actuator of the transmission controls a reverse gear synchronizer 16 to mesh with a first gear driven gear 17, and all the other synchronizers do not mesh with any gear gears. At this time, the power from the input shaft 1 sequentially passes through the input shaft constant meshing gear 28, the middle shaft constant meshing gear 5, the middle shaft 10, the first gear driving gear 8, the first gear driven gear 17, the first reverse gear synchronizer 16, the middle gear The two shafts 14, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com