Vacuum drying box for drying ethyltriphenylphosphonium bromide

A technology of ethyltriphenylphosphine bromide and vacuum drying oven, which is applied in the direction of drying solid materials, drying chamber/container, drying gas arrangement, etc., can solve the problems of unfavorable long-term storage, unfavorable unified management, poor safety, etc., and achieve Realize the effect of long-term stable storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

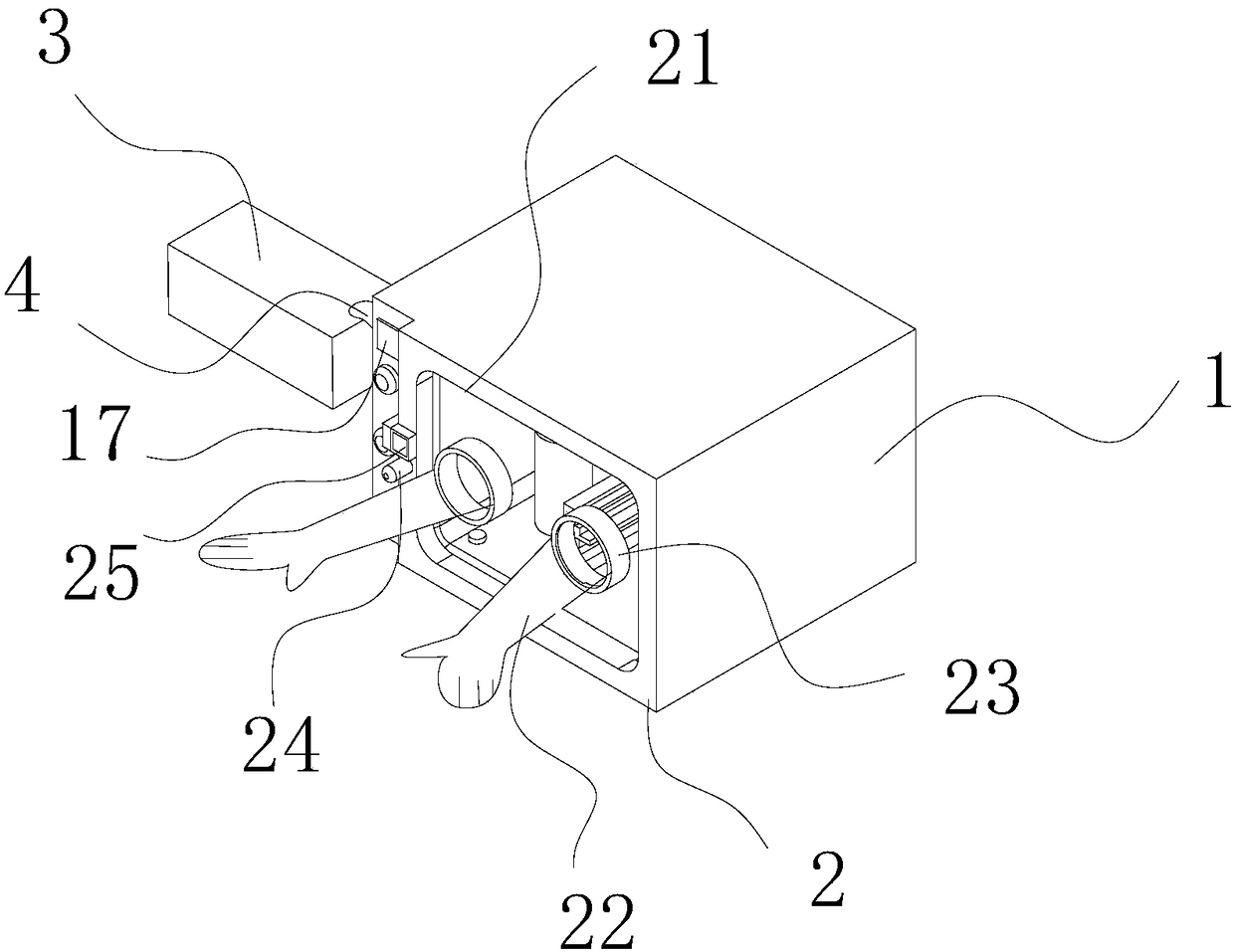

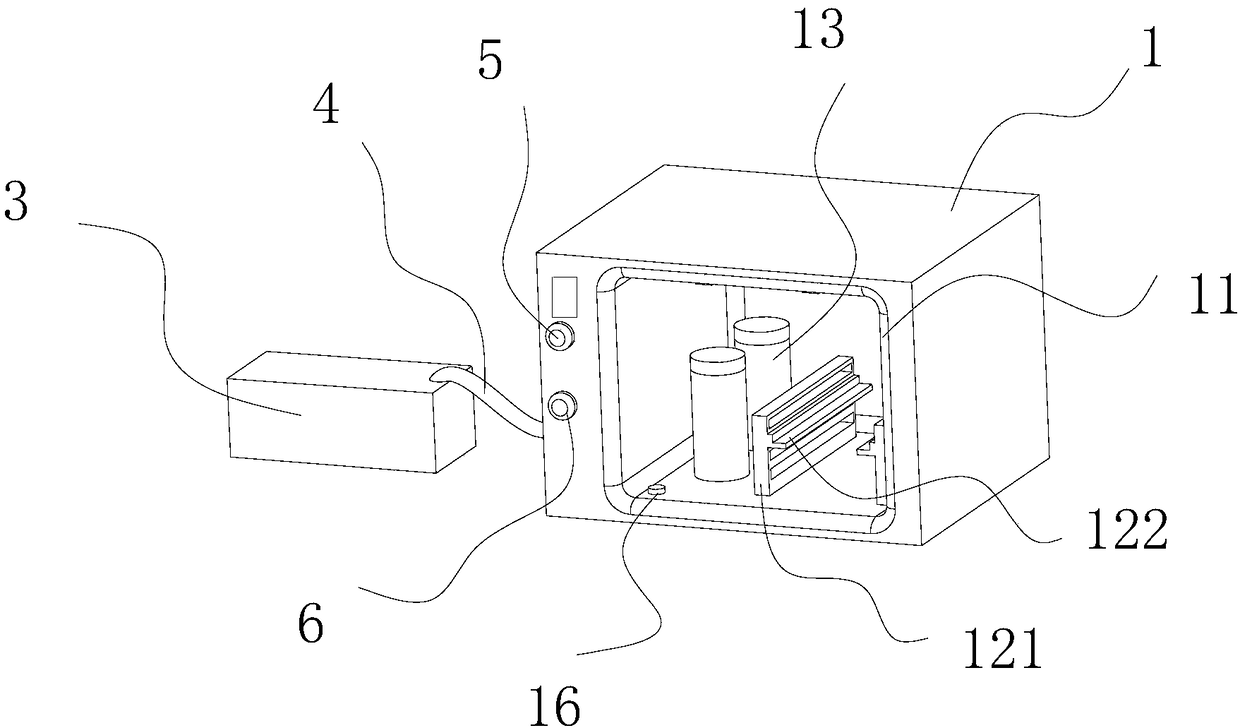

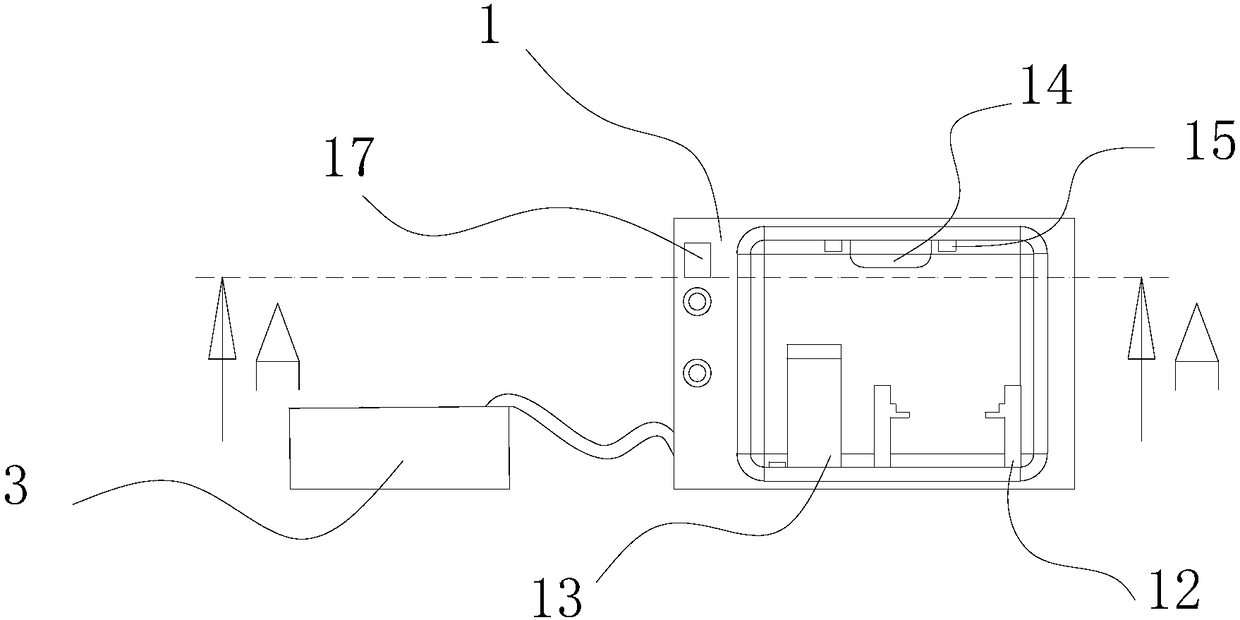

[0027] Such as Figure 1-4 As shown, a vacuum drying oven for ethyltriphenylphosphine bromide drying in this embodiment has a simple structure and is easy to use, and includes a box body 1, a box door 2 and a vacuum pump 3, wherein the box body 1 is an inner A rectangular box body of a drying chamber 11 is provided, and the outer end of the box body 1 is connected to a vacuum pump 3 through an air pipe 4 .

[0028] The top corners of the drying chamber 11 are arc angles, one side of the drying chamber 11 is provided with a pair of holders 12, and the other side is provided with two sealed tanks 13, wherein the holders 12 specifically include The frame 121 that is arranged on the bottom of the drying chamber 11 and the angle steel 122 that is fixed on the frame 121 and is used to support the tray (not shown in the figure); in addition, the bottom of the drying chamber 11 is also provided with a temperature detector 16, The temperature detector 16 is connected with the temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com