Tensile fracture determining method for crack forming period of steel and iron material

A technology for steel materials and determination methods, which is applied in the analysis of materials, the use of stable tension/pressure to test the strength of materials, and the preparation of samples for testing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

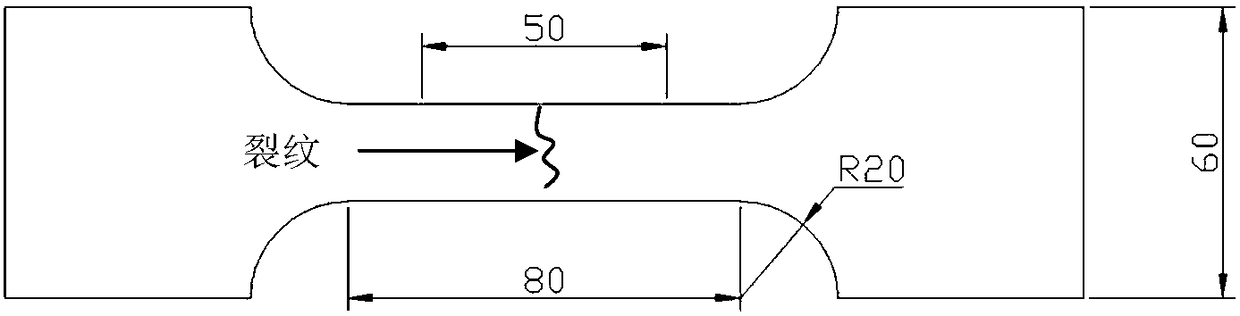

[0019] Take a crack inside a Q345D bar with a specification of Φ250mm as an example. The crack was found during low-magnification inspection. In order to protect the appearance of the crack, clean anti-rust oil was dripped on the crack to isolate air and water, and wrapped with tape Prevent the loss of anti-rust oil. A tensile sample containing cracks is processed at the crack. The thickness of the tensile sample is 5mm and the length is 150mm. It is stretched at room temperature on a computer-controlled electronic universal testing machine. In order to ensure that the sample breaks along the crack, the beam of the tensile testing machine The displacement speed was set at 0.01 mm / min until the sample fractured along the crack, and the two crack surfaces were mechanically separated without destroying the original morphology of the crack surface. In order to prevent the broken fracture from being oxidized or corroded by long-term contact with air, dust and water, the fracture sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com