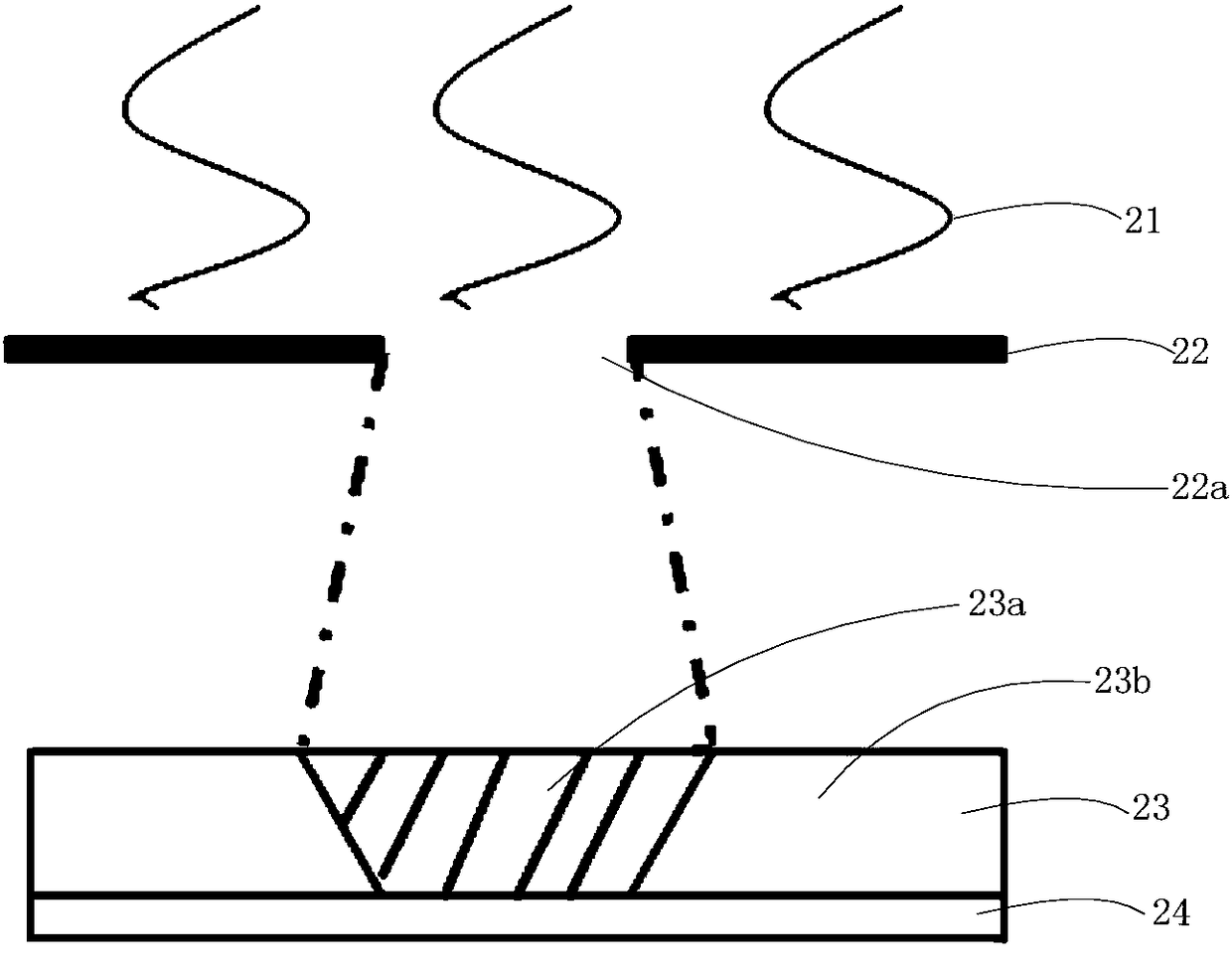

Formation method of isolation column in photoresist inverted trapezoidal structure

An inverted trapezoidal, photoresist technology, applied in the field of photolithography, can solve the problems that cannot be separated by evaporation materials, can not satisfy the isolation of evaporation materials, and the slope is small.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] The design size of the isolation column is 10 microns, or in other words, the width of the light-transmitting hole on the mask plate is 10 microns. The preparation process of the isolation column is as follows:

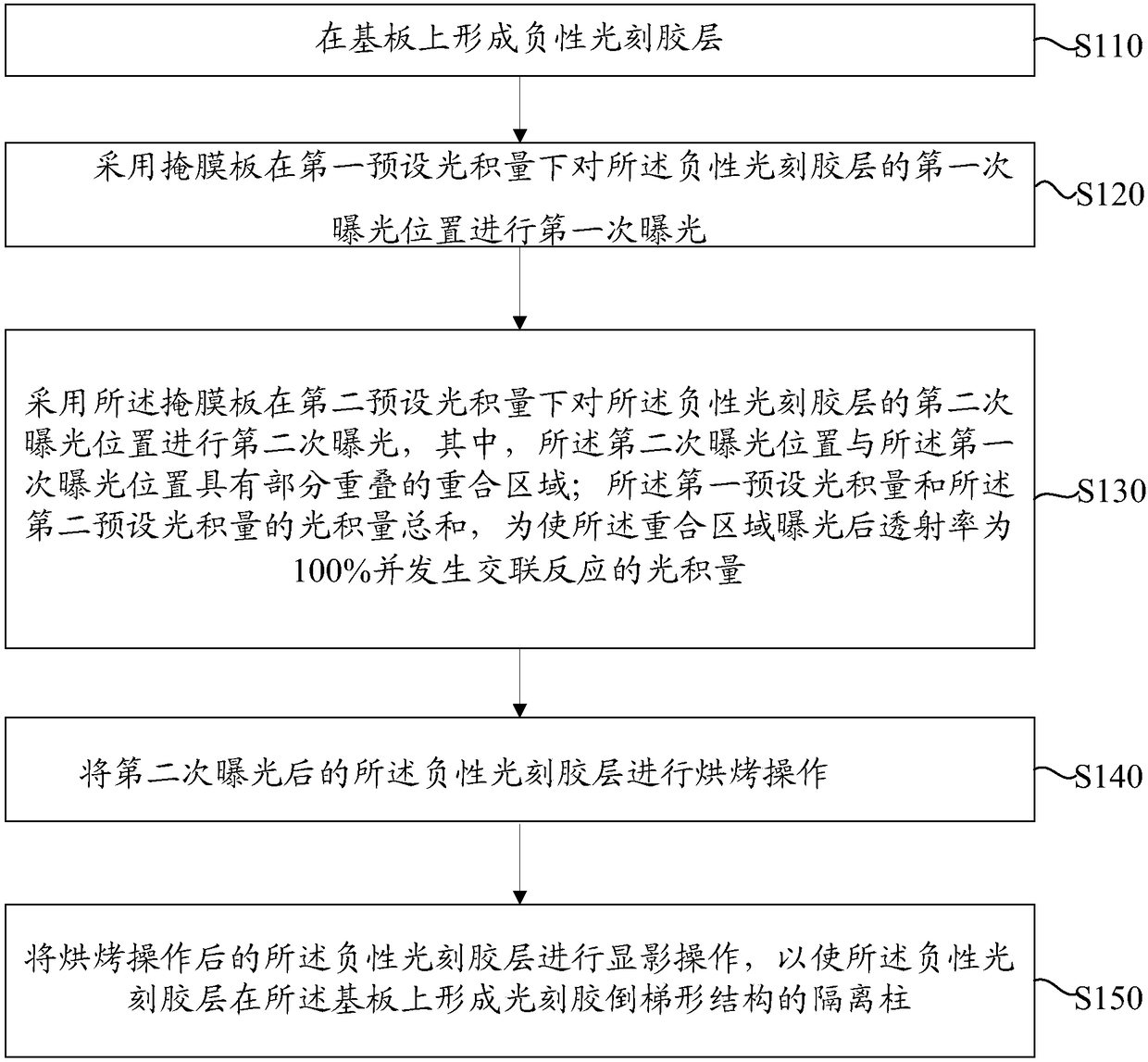

[0060] A method for forming an isolation column of a photoresist inverted trapezoidal structure, comprising the steps of:

[0061] A negative photoresist layer is formed on the substrate; wherein, the thickness of the negative photoresist layer is 4.2 microns.

[0062] Using a mask plate to expose the first exposure position of the negative photoresist layer under the first preset light product amount; wherein, the first preset light product amount is 105mj / cm 2 (mJ / cm2); the exposure machine is used to perform the first exposure operation, and the wavelength of the exposure machine is selected from G Line and H Line.

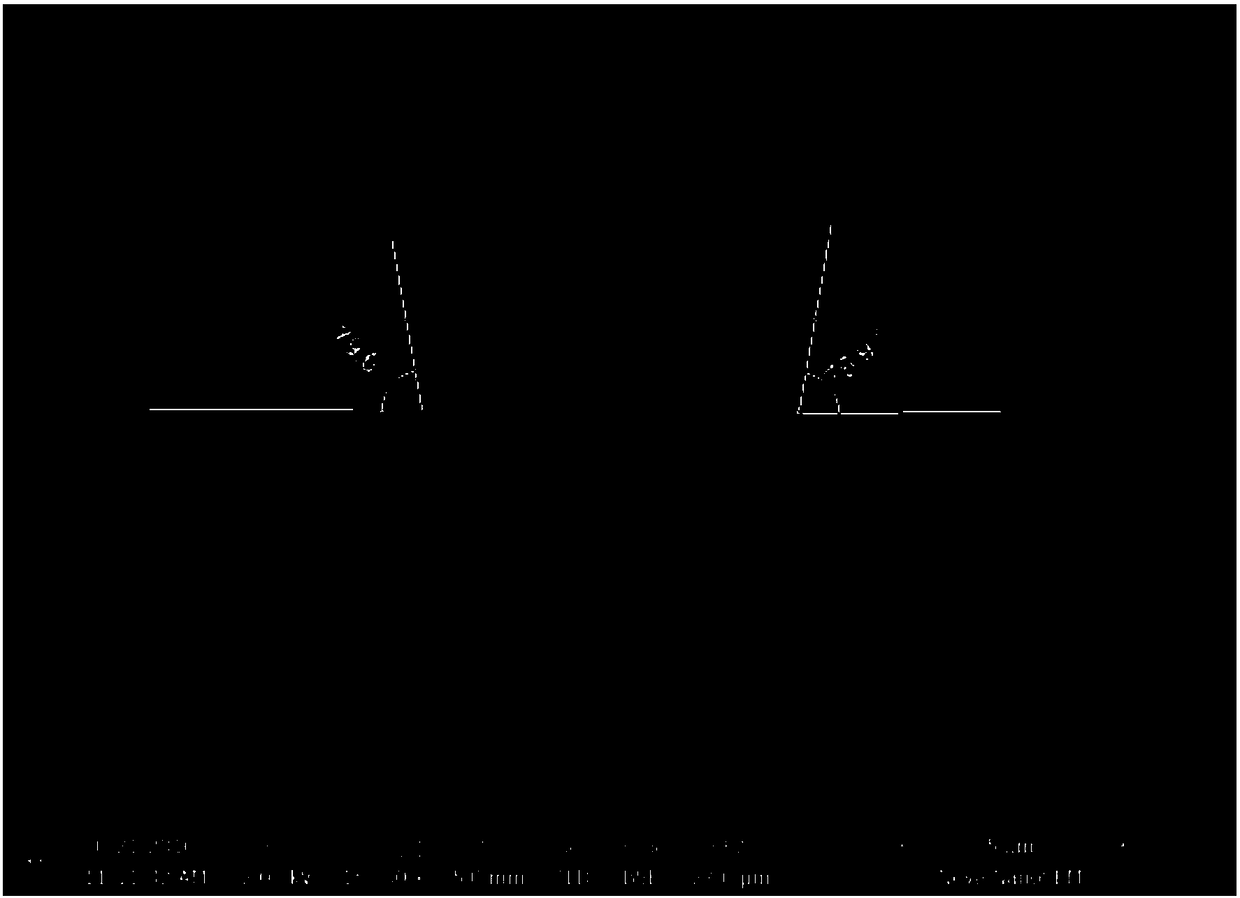

[0063] On the basis of the first exposure position, the substrate is translated by 5 microns along the width direction of the light transmiss...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com