Drive breaking tooth roller internally provided with hydraulic motor

A technology of hydraulic motors and crushing teeth is applied in the field of engineering crushing equipment, which can solve the problems of large space occupation, complex structure and inability to use, and achieve the effect of large occupation space and complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

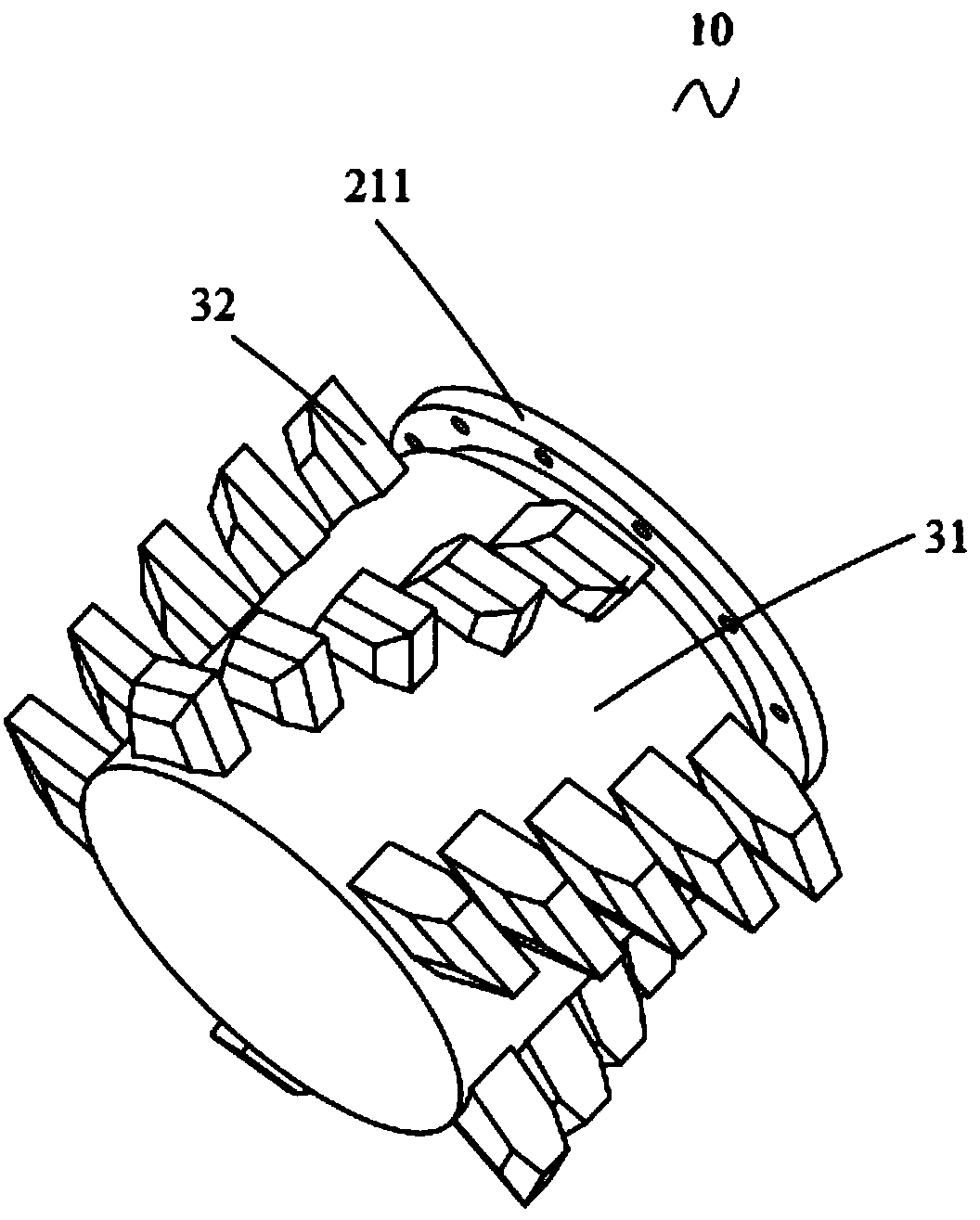

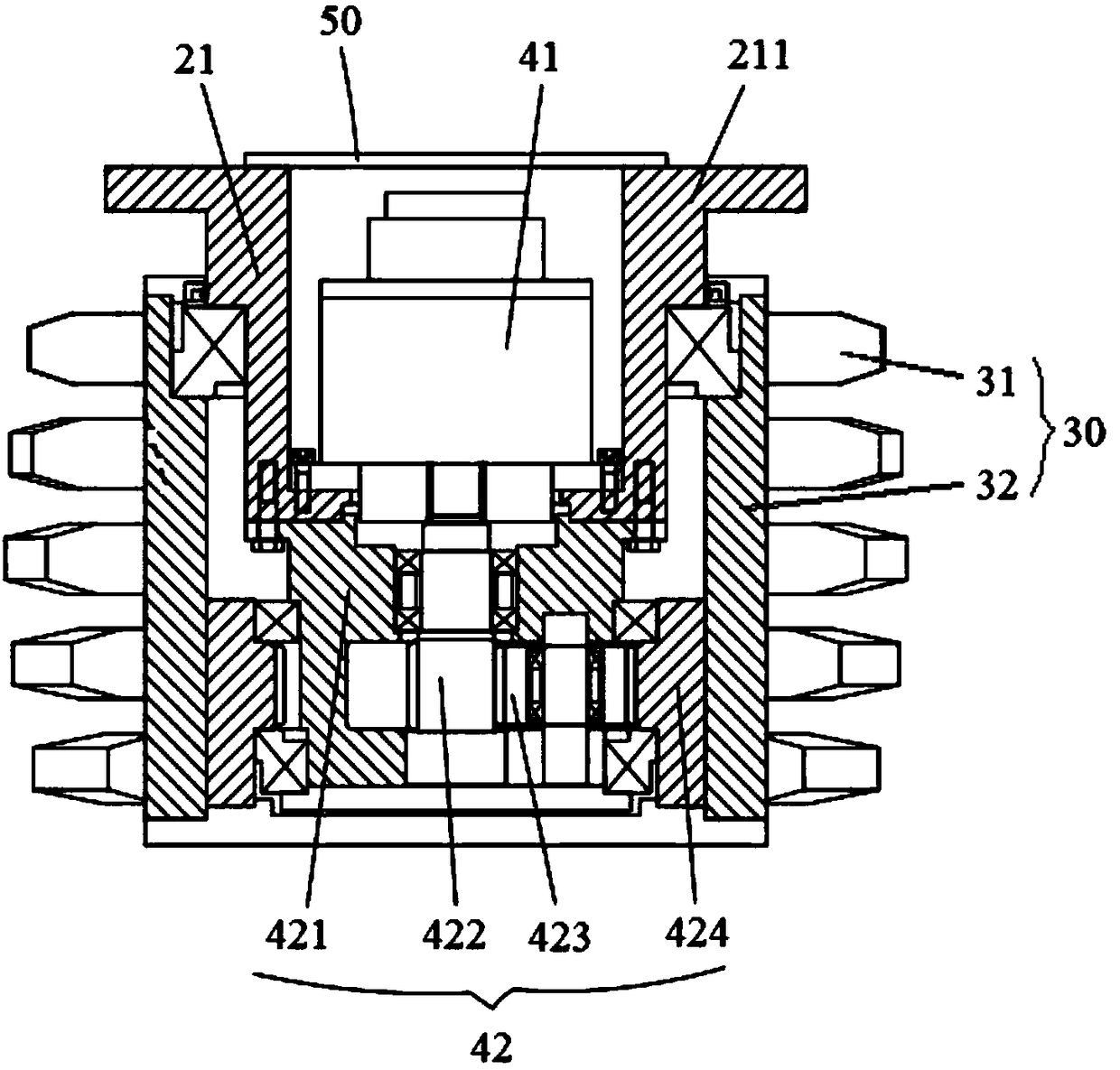

[0015] Please see Figure 1 to Figure 2 , the embodiment of the present invention provides a built-in hydraulic motor to drive the crushing toothed roller 10, including a circular fixing part, a crushing part 30 and a driving device, the circular fixing part is fixed on the upper end of the crushing part 30, and the circular fixing part and the The part 30 forms an internal cavity to install the driving device, and then the driving device drives the crushing part 30 to rotate to crush the material; the circular fixing part includes a circular fixing sleeve 21, and the crushing part 30 includes a circular roller body cover 31 and crushing teeth 32 , the crushing tooth 32 is fixed on the outer wall of the circular roller body cover 31 to crush the material, the circular fixed cover 21 is connected with the circular roller body cover 31 through the driving device to form an internal cavity to install the driving device, An arc-shaped installation edge 211 is arranged on the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com