Sand casting production technology

A production process and sand core technology, applied in the direction of casting molds, casting mold components, manufacturing tools, etc., can solve the problems of lower product production efficiency, high melting point, alienation, etc., and achieve the effect of shortening the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

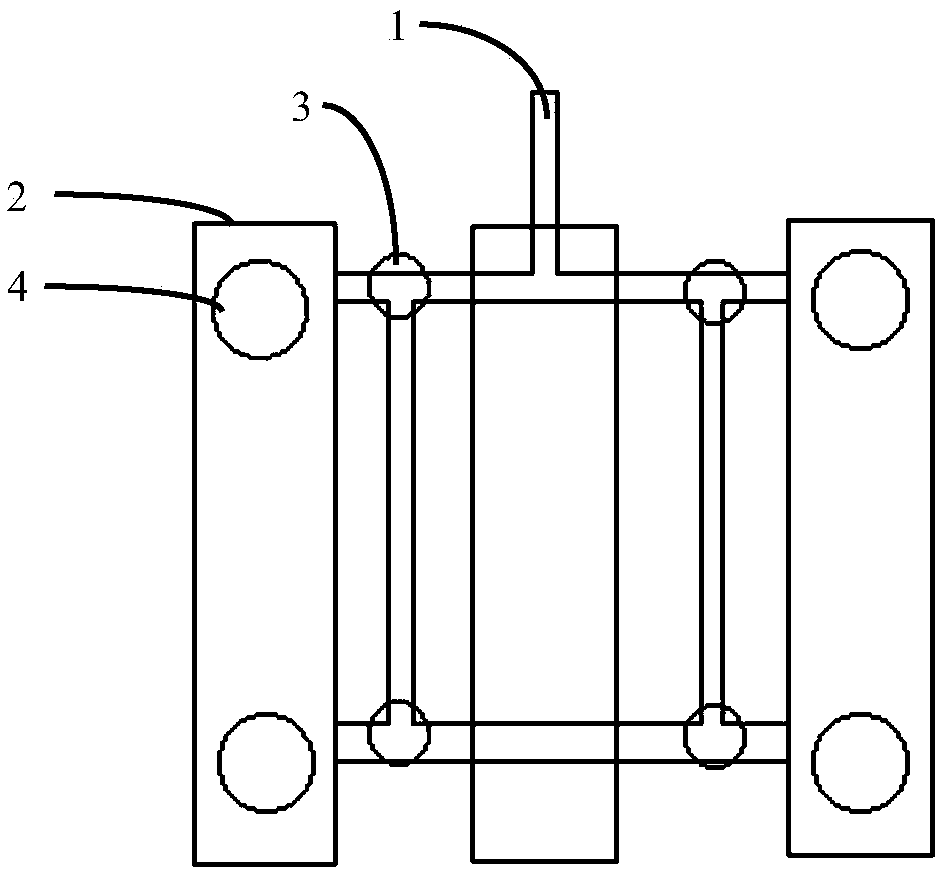

[0054] Such as figure 1 Shown is the product stand base that needs to be produced,

[0055] According to the shape of the support base, the shape of the cavity to be constructed by the sand core and the shape can be determined, and the shape of the sand core and the shape can be determined at the same time. The shape constructed between the sand core and the shape includes the sprue 1, the bracket The base 2, the side riser 3 and the open riser 4, the side riser 3 is set between the pipes of the support base 2, which can feed the pipes during the pouring process, effectively reducing the size of the mold and reducing the production cost. The amount of sand used in the process, the open riser 4 is set on the pipeline, and the runner passes through the side riser to connect to various parts, so that the temperature loss of the slurry entering the side riser is reduced during the flow process, and the side riser is improved. The feeding efficiency of the mouth is improved and tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com