A special fixture for turning of automobile rear brake drum

A special fixture and brake drum technology, applied in the direction of the chuck, etc., can solve the problems of interference in turning, small application range, easy damage to tools, etc., and achieve the effect of long service life, prevention of loose connection, and high strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

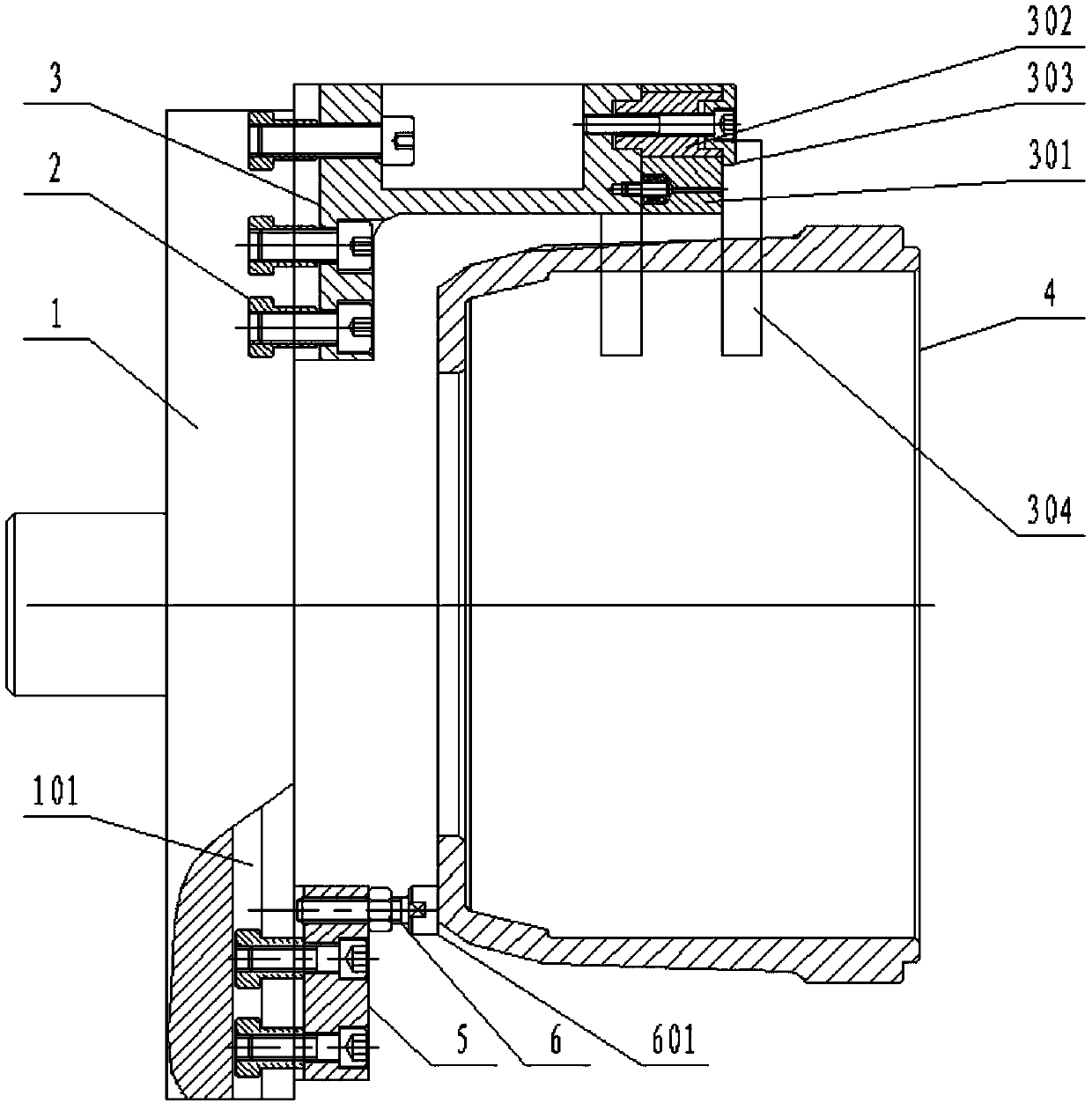

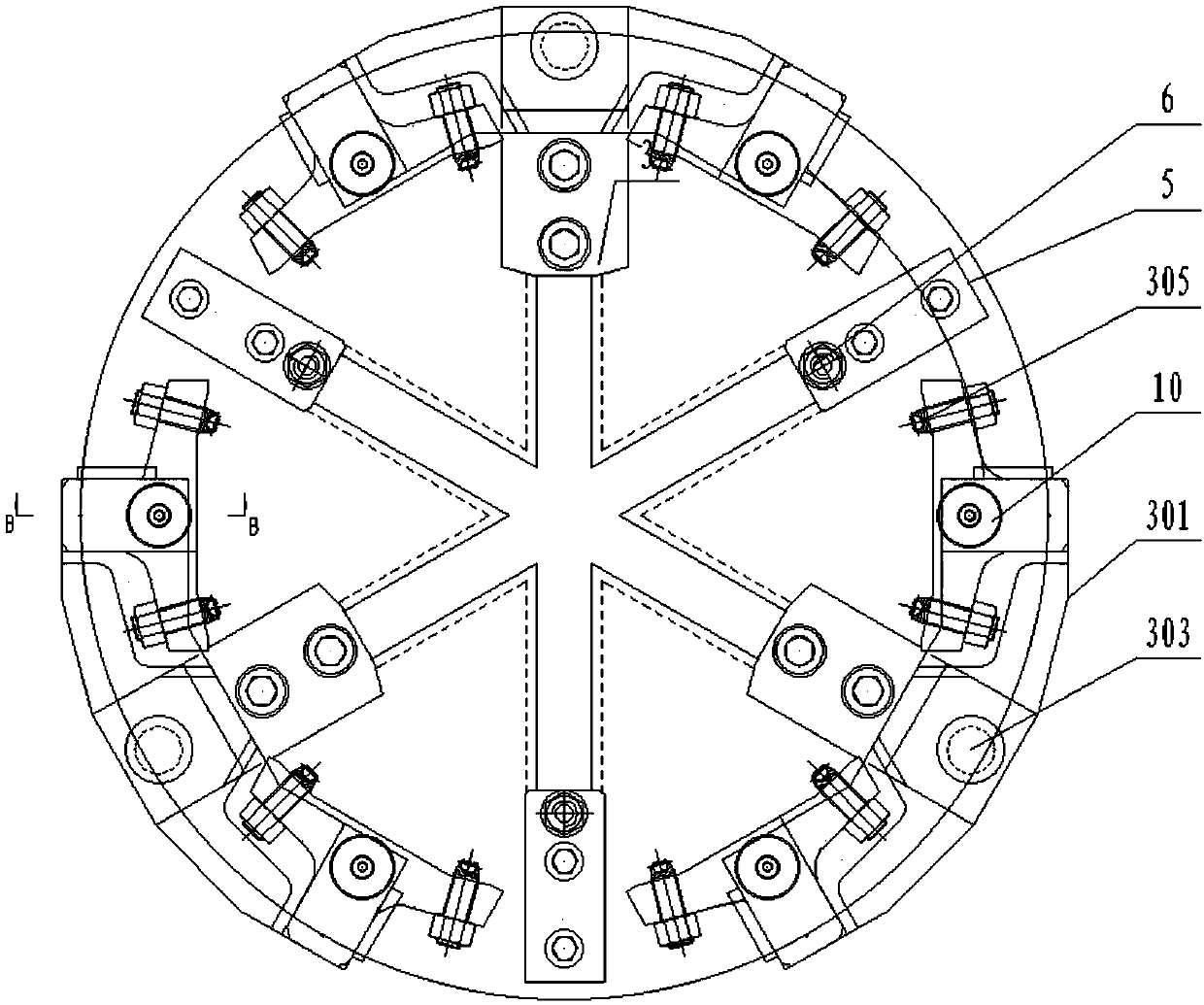

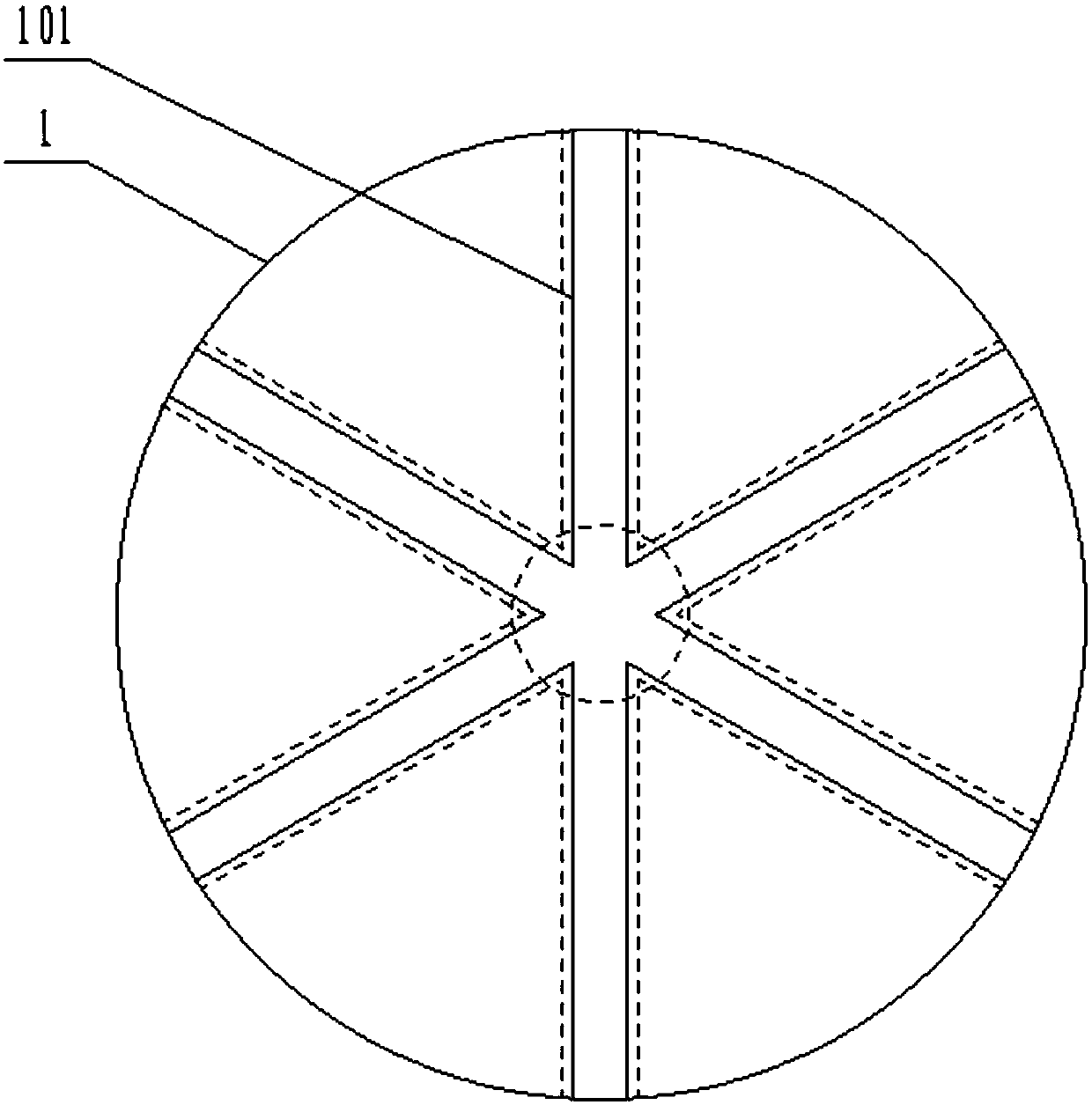

[0040] as attached figure 1 to attach Figure 13Shown: a special fixture for turning the rear brake drum of an automobile, including a rotating disk 1, a T-shaped slot 101, a T-shaped nut 2, an adjusting arm 3, a receiving block 301, a connecting block 302, a first gland 303, a clamp Claw 304, moving ball screw 305, rear brake drum 4, positioning block 5, positioning screw 6, knurled head 601, optical axis screw 7, sealing ring 8, compression sleeve 9 and second gland 10; T type The nut 2 is a T-shaped stepped shaft structure, with a threaded through hole in the middle, placed in the T-shaped slot 101, and used to fix the parts to the rotating disk 1 through bolt connection; five screw holes are opened on the receiving block 301 and a counterbore, which are fixed on the right end face of the adjusting arm 3 through bolt connection and tight connection, and its middle part protrudes front and back, so that the thickness of the left and right ends is smaller than the thickness ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com