Automatic tool-changing machining equipment

A technology of processing equipment and automatic tool change, applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve the problems that the tool library cannot cooperate with the robot, prolong the processing time of the workpiece, and the structure of the processing center is not good, and improve the Production and processing efficiency, simple structure, and the effect of shortening the tool change stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the technical means, creative features, objectives and effects of the invention easy to understand, the present invention will be further elaborated below in conjunction with specific diagrams.

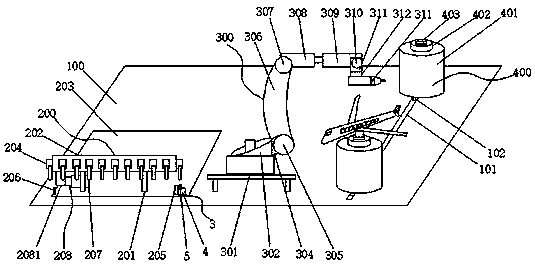

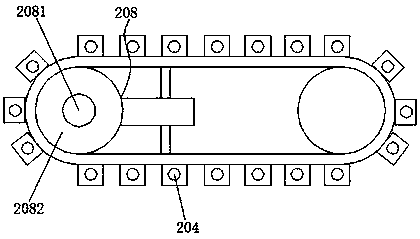

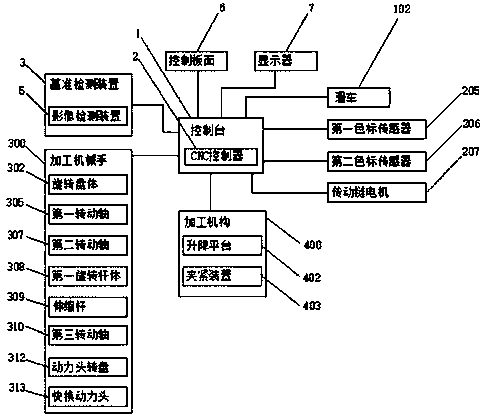

[0034] Such as Figure 1-3 As shown, a kind of automatic tool changing processing equipment of the present invention, wherein, comprises working platform 100, and the upper side of working platform 100 is respectively provided with tool library 200, processing manipulator 300 and processing mechanism 400, and processing manipulator 300 is located at tool magazine 200 and Between the processing mechanism 400, the tool magazine 200, the processing manipulator 300 and the processing mechanism 400 are all controlled and connected to a console 1, and the console 1 sends instructions to control the work of the tool magazine 200 to run the required tools to the distance from the processing manipulator. 300 position of the shortest stroke, control the processing manipu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com