Protection device of bamboo hat type disc type tool magazine

A technology of protective device and disc cutter, used in positioning devices, maintenance and safety accessories, clamping and other directions, can solve the problems of large tool changing stroke, high requirements for guide rail and screw, affecting machining accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

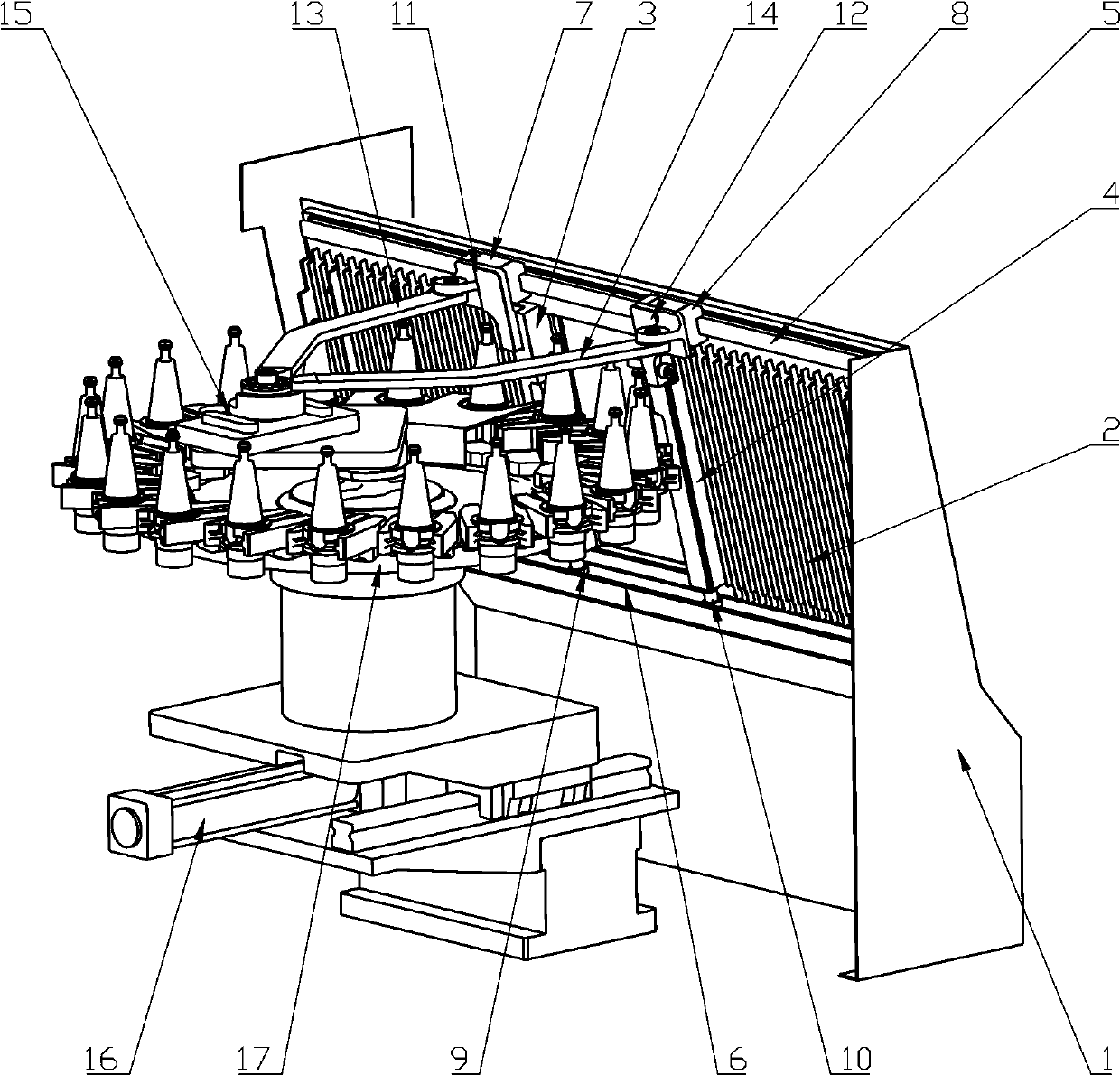

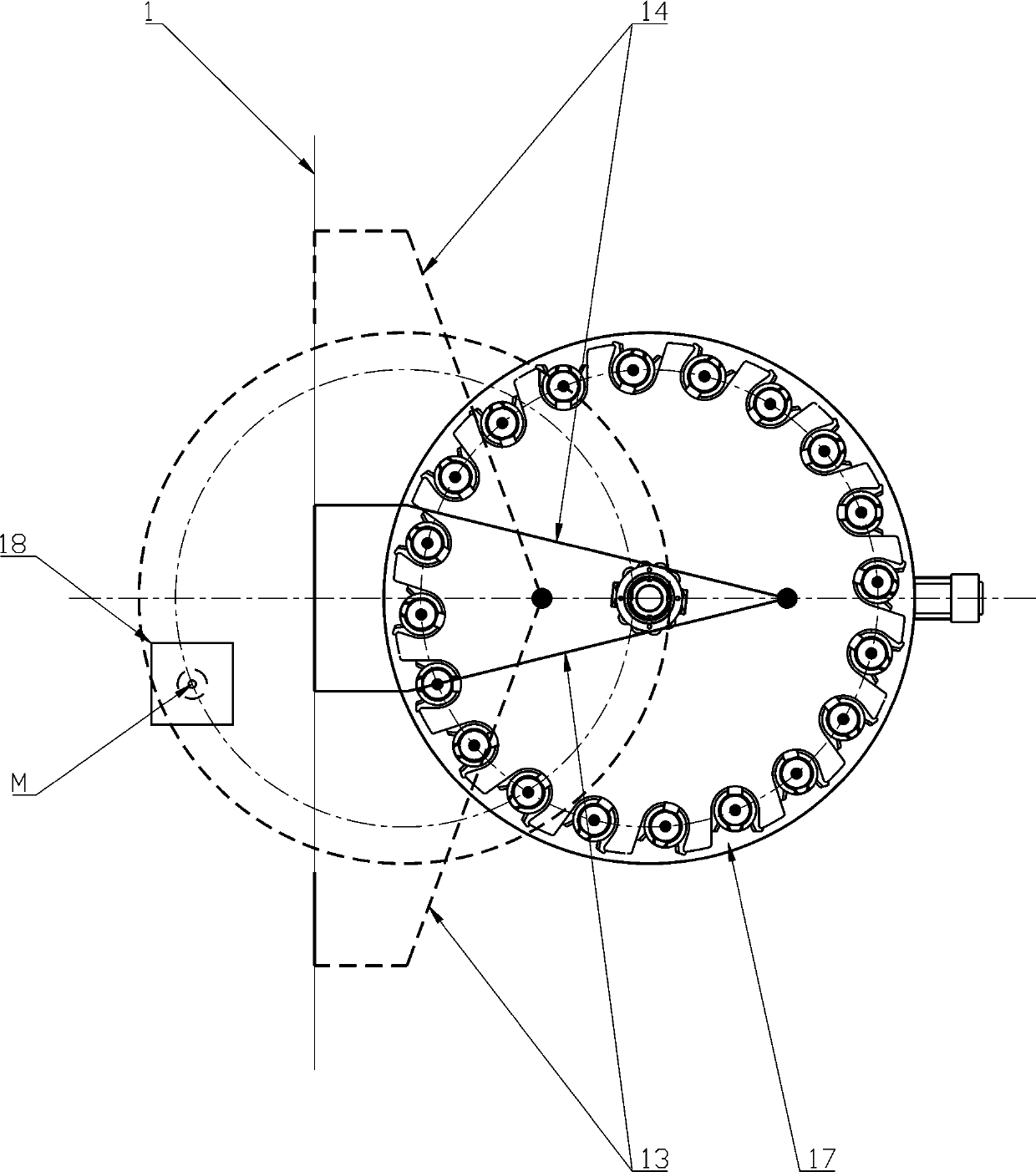

[0016] combine figure 1 and figure 2 As shown, a protective device of a bamboo hat type disc tool magazine of the present invention consists of a machine tool protection plate 1, a flexible protective cover 2, a left door of the tool magazine 3, a right door of the tool magazine 4, a guide rail 5, a chute 6, a left slide Block 7, right slider 8, left guide wheel 9, right guide wheel 10, left connecting plate 11, right connecting plate 12, left connecting rod 13, right connecting rod 14, connecting rod mounting plate 15 and drive cylinder 16 form.

[0017] The machine tool protective plate 1 isolates the tool magazine from the machine tool processing area. The machine tool protective plate 1 is provided with a knife changing port, and the tool magazine cutter head 17 can be pushed out of the knife changing port under the action of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com