Car body horizontal conveying mechanism for uphill and downhill

A technology of horizontal conveying and conveying mechanism, which is applied in the direction of motor vehicles, transportation and packaging, etc. It can solve the problems of high use cost, high investment cost, production accidents, etc., and achieve the effect of reducing operating cost, reducing energy consumption, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

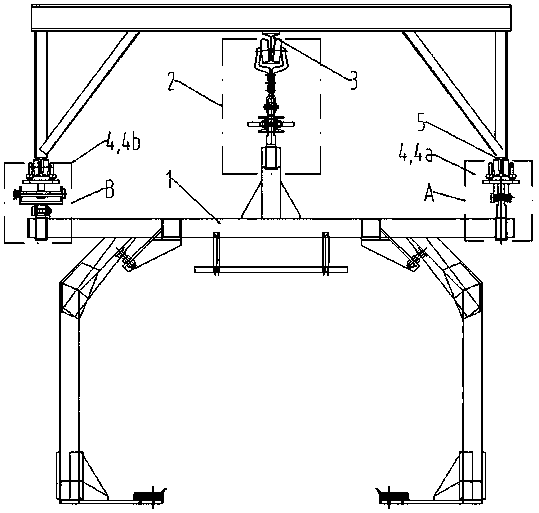

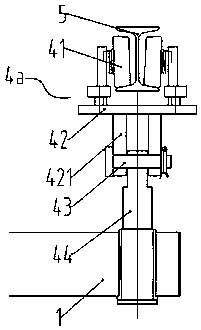

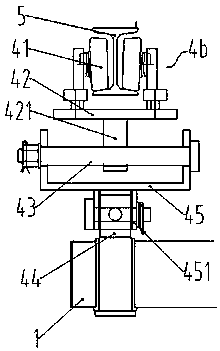

[0024] refer to Figure 1 to Figure 7 , the structural features of the uphill and downhill vehicle body level conveying mechanism are described in detail as follows:

[0025] A horizontal conveying mechanism for up and downhill vehicle bodies, which includes a vehicle body spreader 1, a main sprocket mechanism 2 and a main sprocket track 3; the main sprocket mechanism 2 is fixed at one end of the top of the vehicle body spreader 1, and the main sprocket The sprocket mechanism 2 is slidingly connected to the main sprocket track 3; the conveying mechanism also includes a horizontal auxiliary mechanism 4 located at the other end of the top of the vehicle body hanger 1, and the horizontal auxiliary mechanism 4 includes a pulley 41, a support frame 42, a connecting shaft 43 and Fixing frame 44, described pulley 41 is located at support frame 42 inner sides, and described support frame 42 bottoms are vertically fixed with connecting plate 421, and described connecting plate 421 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com