Dual gun device for continuous desulfurization and blowing desulfurization agent of steel plant

A technology for steelmaking plants and desulfurizers, applied in the field of steelmaking desulfurization, can solve the problems of reduced service life, inability to realize continuous desulfurization production operations, large production load, etc., and achieve the effect of improving overall reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

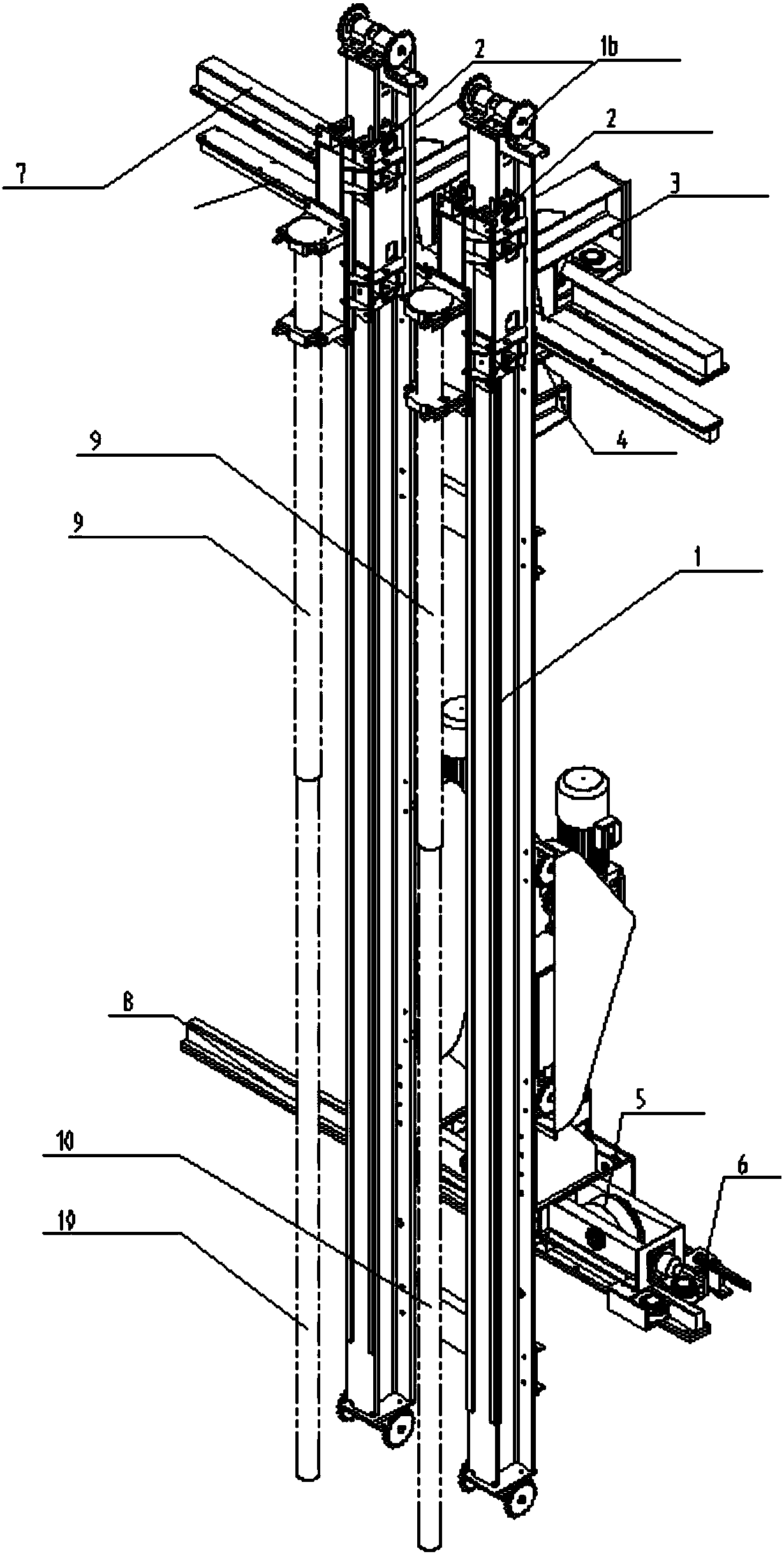

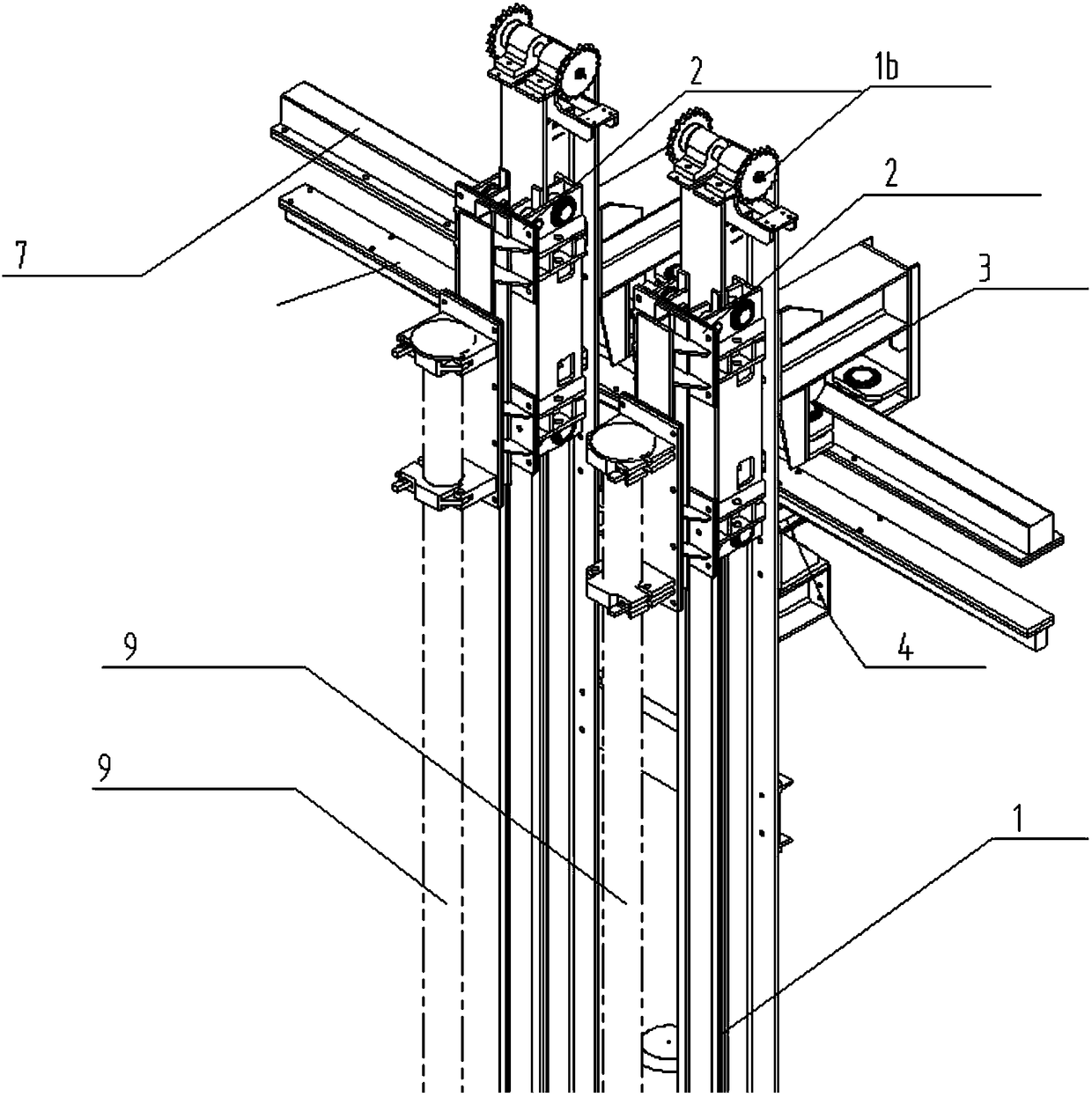

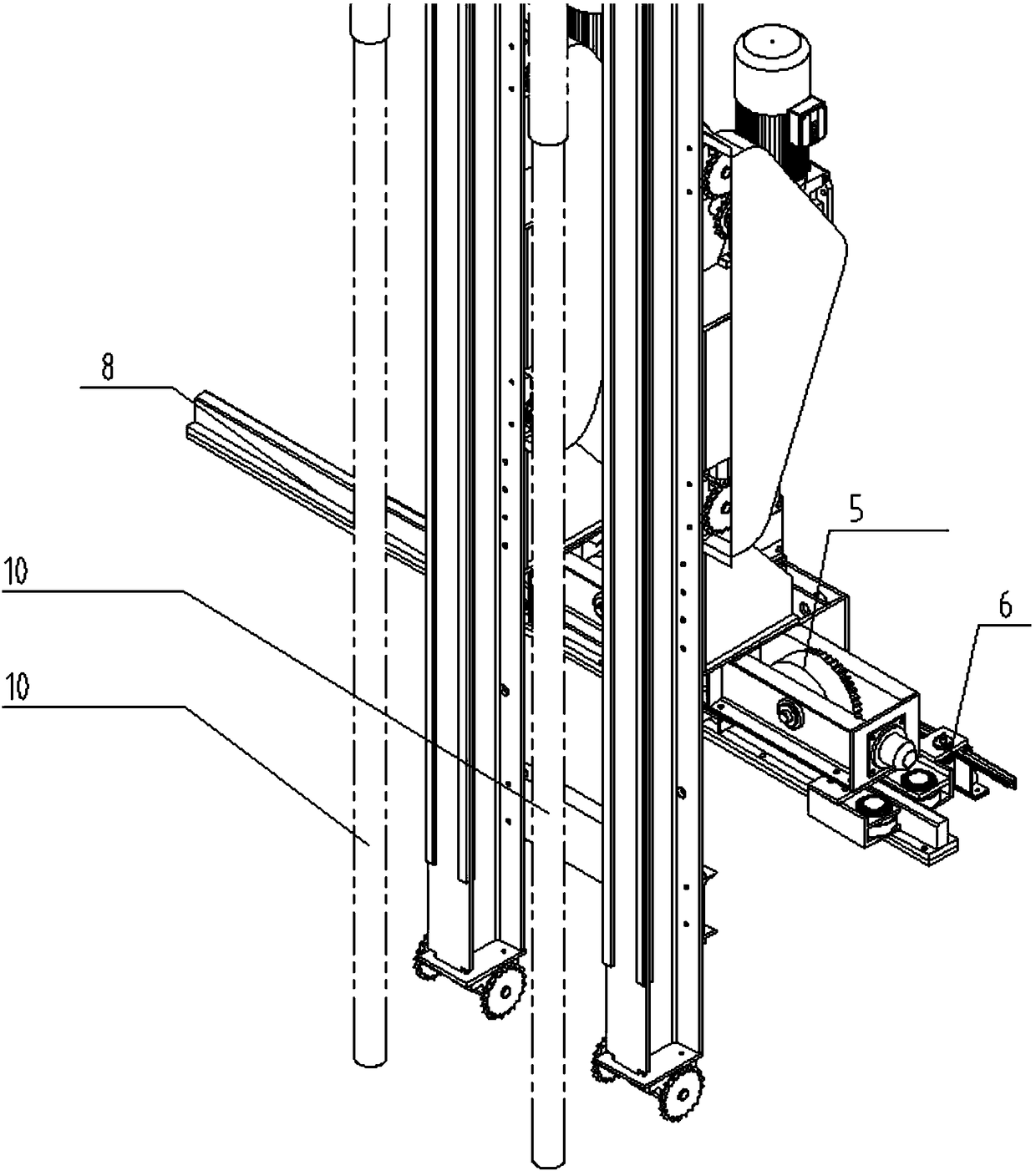

[0037] The invention is set on the hot metal desulfurization process platform of the steelmaking plant, and provides an automatic equipment for the steelmaking plant to realize online gun change and automatic shifting function. The desulfurization spray gun double gun device consists of a single gun device 1 and a lifting car device 2 , upper guide wheel device 3, connecting beam, top wheel device 4, traverse device 5, electrical control and detection device 6, air circuit control system, upper guide rail device 7, lower guide rail device 8, positioning device 12, spray gun fixed section 9 And vulnerable refractory section 10 etc. are formed. as attached figure 1 , 2 , 3 shown.

[0038] Such as Figure 2—Figure 2b The single gun device shown is composed of lifting guide rail, lifting drive device, sprocket device, chain, etc. The lifting gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com