Energy-saving and consumption-reducing prebaked anode preparation method and prebaked anode

A prebaked anode and roasting technology, which is applied in the field of metallurgy, can solve the problems of loose anode bridging structure, low anode density, low strength, and reduced current efficiency, and achieve energy saving, improved reactivity, and low resistivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

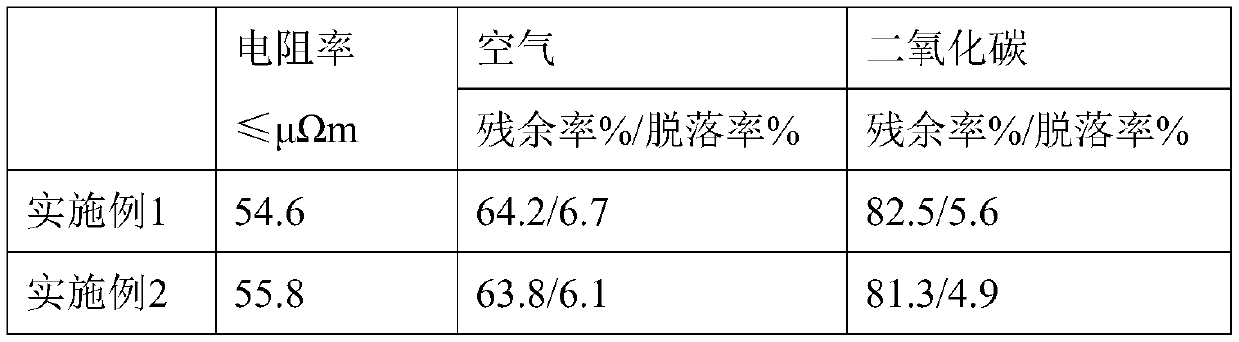

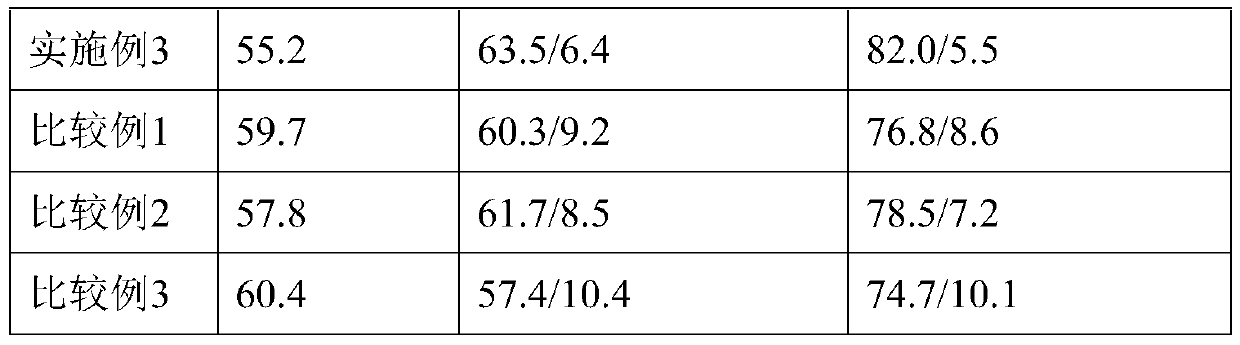

Examples

Embodiment 1

[0074] Sieve and classify the calcined petroleum coke raw materials to obtain the following granules and powders: 25wt% of fine granules with 0.15mm

[0075] Weigh 1.0 kg of coal tar pitch and 0.03 kg of additive palmitic acid; and weigh 0.05 kg of the aforementioned powder a with a particle size of ≤0.15 mm.

[0076] Mix and knead the coal tar pitch, additives and powder a evenly, preheat to 180°C; then add the pellets and the remaining powder, knead evenly, heat to 180°C, take it out after 20 minutes, and obtain the mixed paste;

[0077] Put the mixed paste into the mold in batches, hot press molding, molding at 50MPa, and hold the pressure for 1min to obtain the prebaked anode ...

Embodiment 2

[0080] Sieve and classify the calcined petroleum coke raw materials to obtain the following granules and powders: 25wt% of fine granules with 0.15mm

[0081] Weigh 1.1 kg of coal tar pitch and 0.035 kg of additive palmitic acid; and weigh 0.06 kg of the aforementioned powder a with a particle size of ≤0.15 mm.

[0082] Mix and knead coal tar pitch, additives and powder a evenly, preheat to 160°C; then add granules and the remaining powder, knead evenly, heat to 160°C, take it out after 30 minutes, and obtain a mixed paste;

[0083] Put the mixed paste into the mold in batches, hot press molding, molding at 50MPa, and hold the pressure for 1min to obtain the prebaked anode green bl...

Embodiment 3

[0086] Sieve and classify the calcined petroleum coke raw materials to obtain the following granules and powders: 25wt% of fine granules with 0.15mm

[0087] Weigh 0.95 kg of coal tar pitch and 0.025 kg of additive palmitic acid; and weigh 0.04 kg of the aforementioned powder a with a particle size of ≤0.15 mm.

[0088] Mix and knead coal tar pitch, additives and powder a evenly, preheat to 170°C; then add granules and the remaining powder, knead evenly, heat to 170°C, take it out after 25 minutes to obtain a mixed paste;

[0089] Put the mixed paste into the mold in batches, hot press molding, molding at 50MPa, and hold the pressure for 1min to obtain the prebaked anode green blo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com