Compressor core flexible supporting structure

A flexible support, compressor technology, applied in the field of compressors, can solve problems such as large movement of the movement and compressor collision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

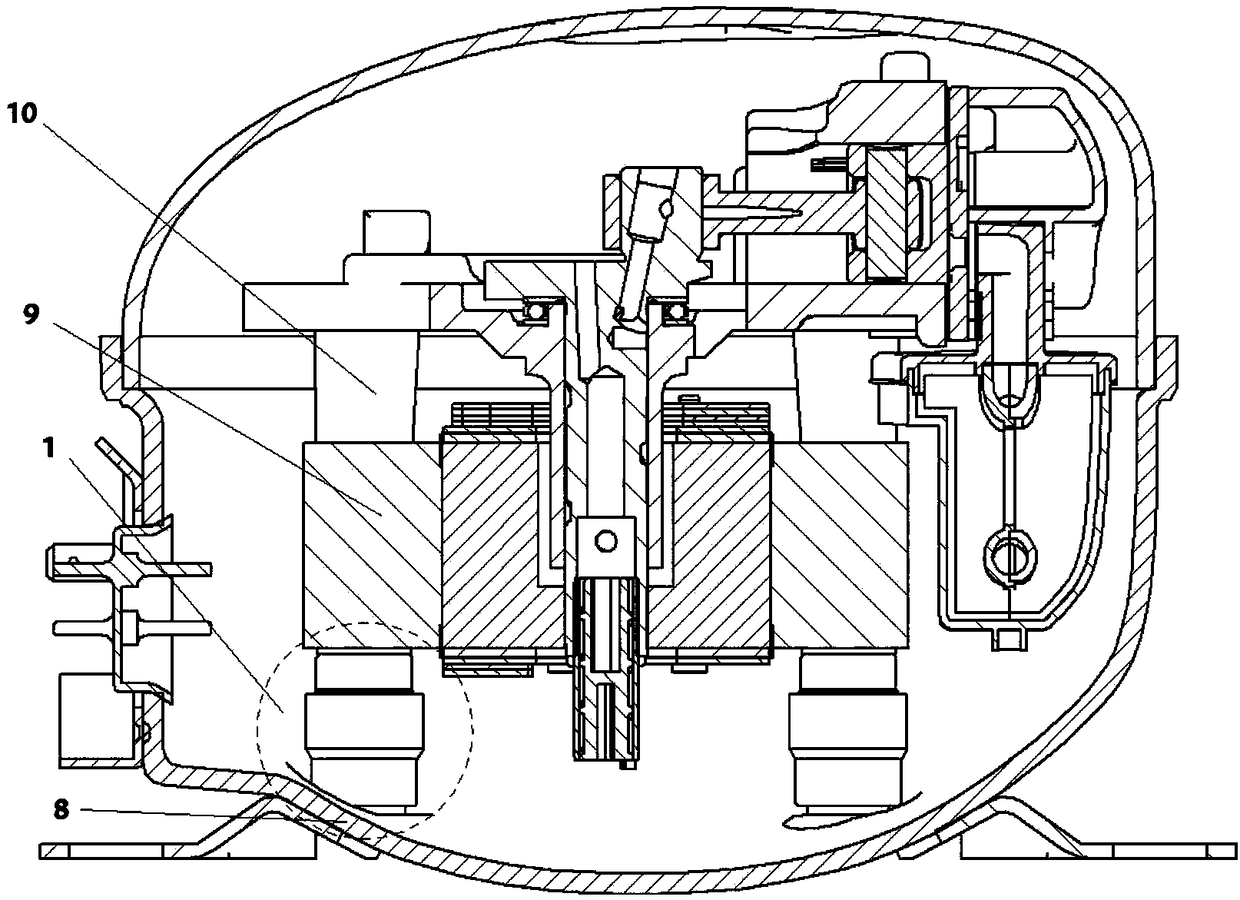

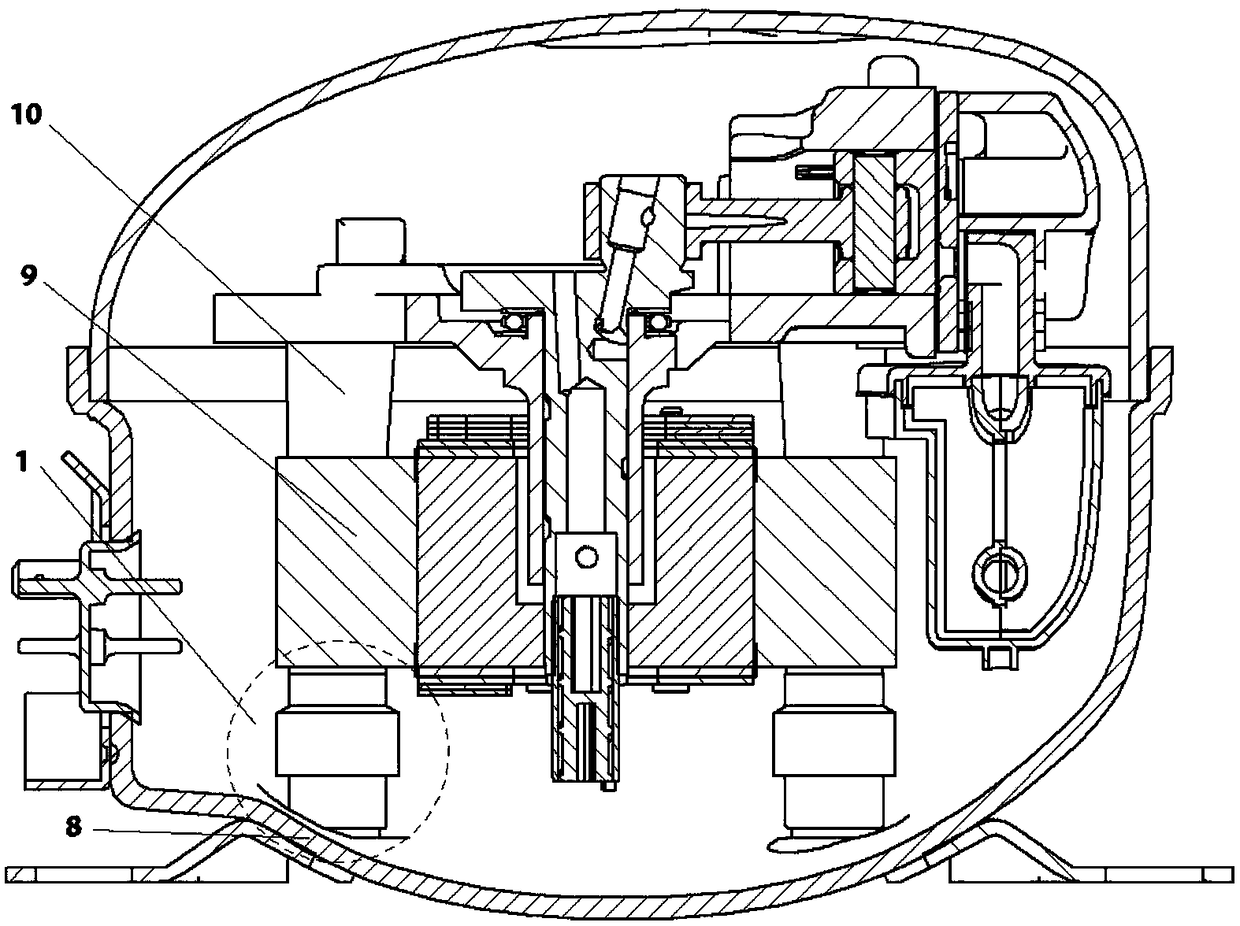

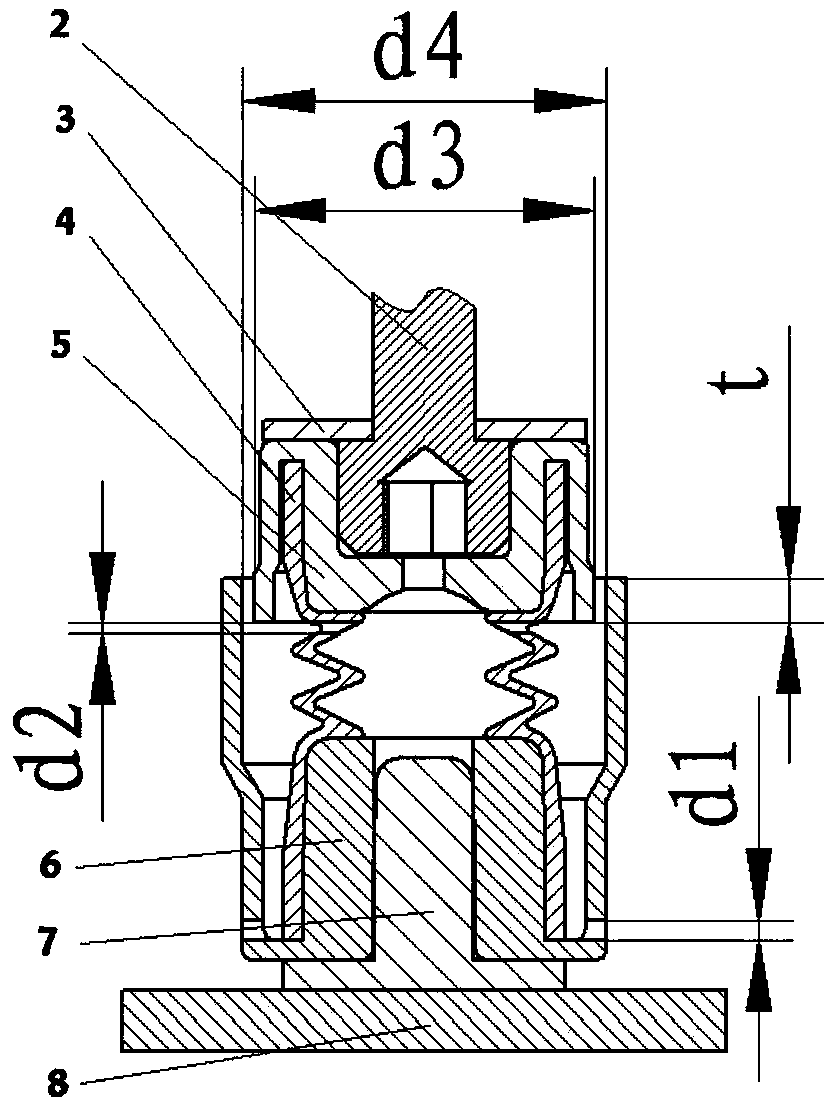

[0019] Such as figure 1 and figure 2 As shown, the flexible supporting structure 1 of the compressor core of the present invention is arranged in the compressor housing 8 . please combine image 3 As shown, the compressor core supporting structure 1 fixes the stator 9 on the crankcase 10 through screws 2 . During installation, first put the washer 3 on the screw 2, and fix the stator 9 on the crankcase 10. After installation, press the upper bushing 5 on the screw 2, and the whole movement is installed.

[0020] Such as image 3 As shown, the flexible supporting structure 1 of the compressor core of the present invention includes a gasket 3 , an elastic element 4 , an upper bush 5 , a lower bush 6 and a stud 7 . The elastic element 4 is made of high damping material, such as high damping rubber. The middle area of the elastic element 4 presents a bellows shape, so as to facilitate the volume change of the inner cavity of the elastic element 4 . The upper part of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com