Serial elastic transmission device based on integral flexible hinge spring

A technology of flexible hinge and transmission device, applied in the field of flexible transmission, can solve the problems such as defective fixing and preloading of the series elastic driver, poor overall rigidity of the series elastic driver, affecting the motion accuracy and load capacity, etc., and achieve structural rigidity and stability. High performance, low axial stiffness, and the effect of improving stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

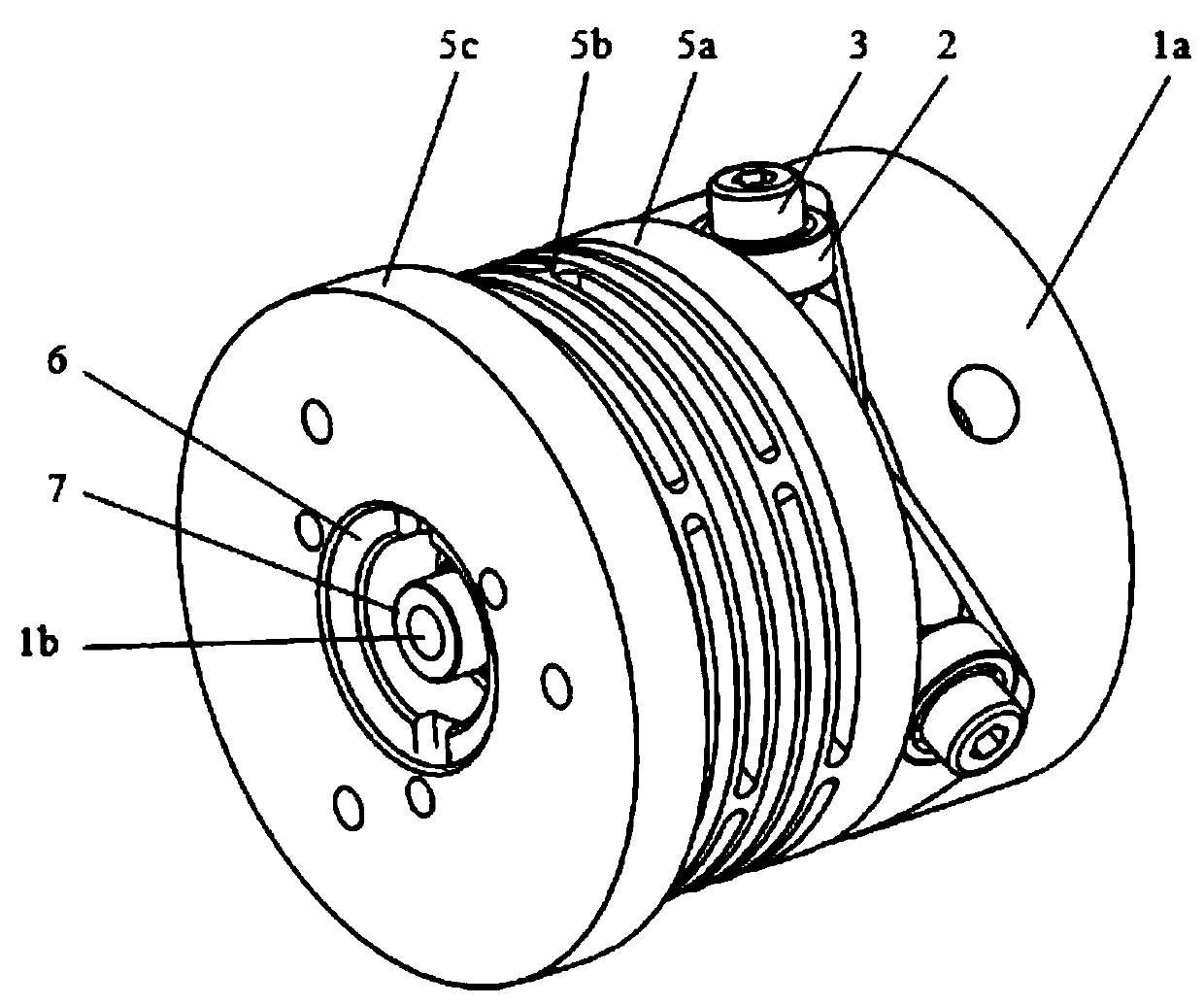

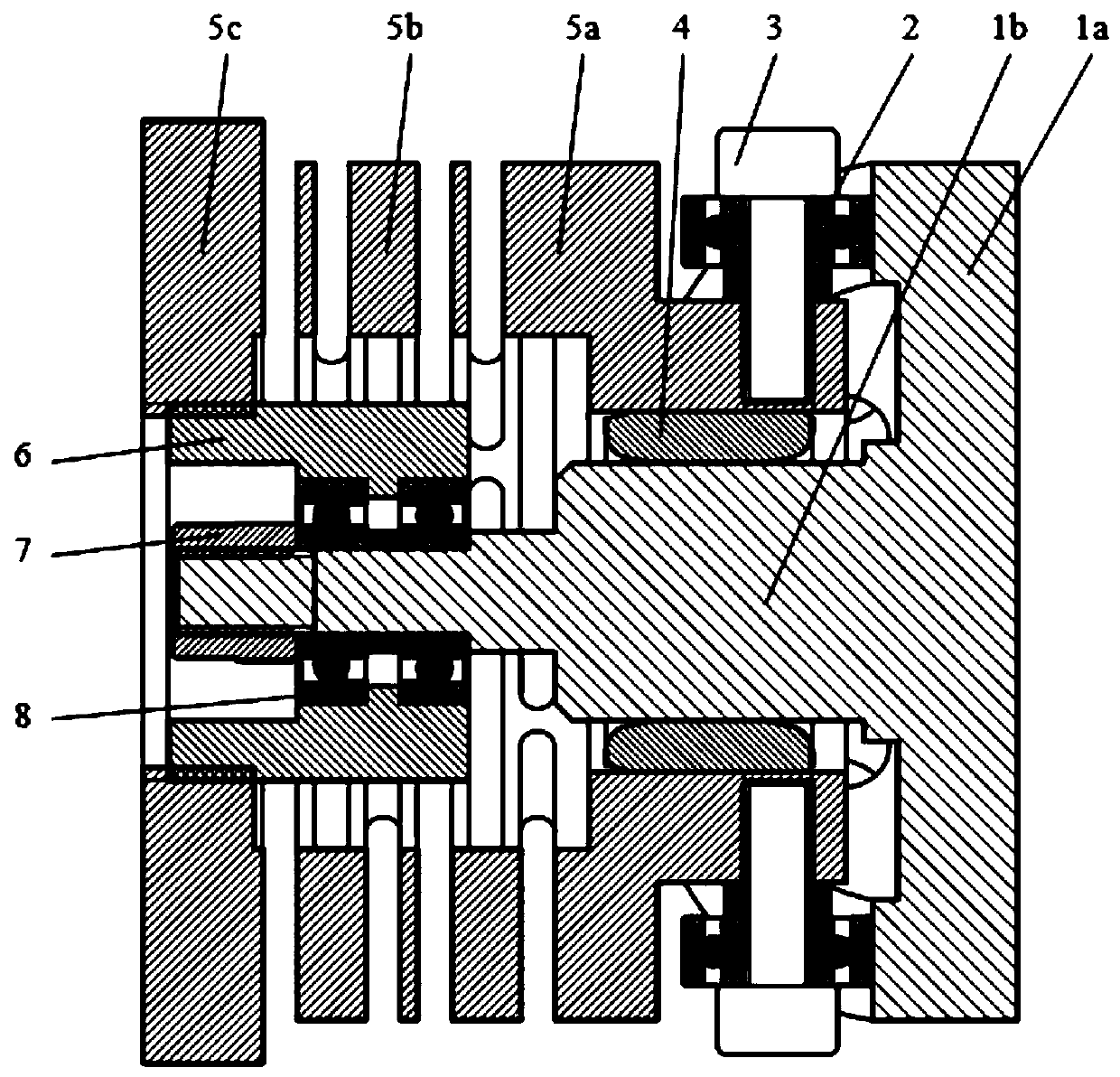

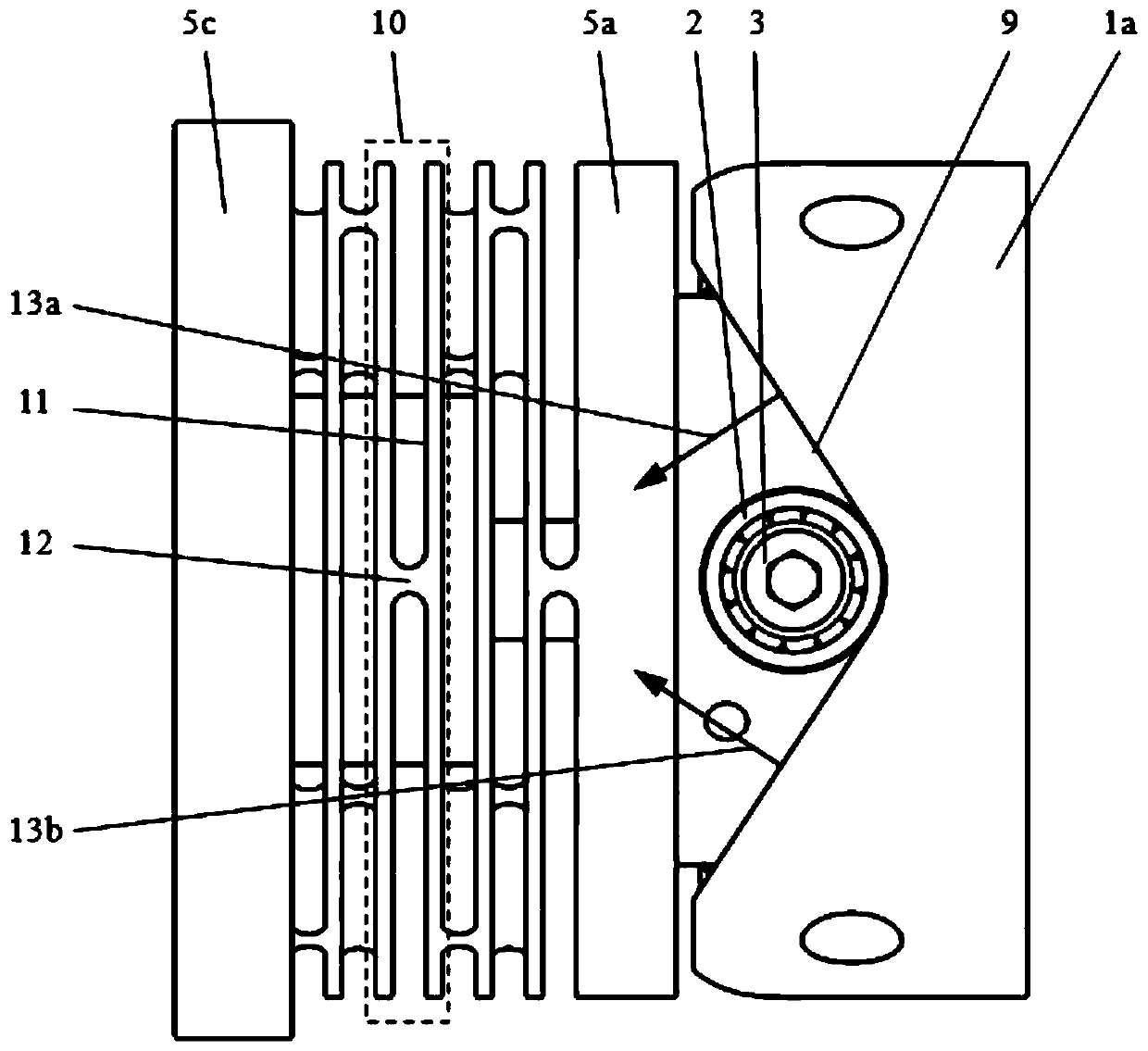

[0028] combine Figure 1-2, the present invention is a series elastic transmission device based on an integrated flexible hinge spring, which consists of an input assembly and an output assembly. The input assembly includes an integrated input plate 1a and a central shaft 1b, which are installed in pairs and Preloaded angular contact ball bearing 8, sliding bearing 4, adjusting sleeve 6 and lock nut 7, the output assembly includes 3 rolling bearings 2, 3 fixing screws 3 (m=3) and an integrated buffer plate 5a, Flexible hinge spring 5b, output plate 5c. The central shaft 1b and the buffer plate 5a are connected by a rolling bearing 2. During the transmission process, the buffer plate 5a will move along the axial direction of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com