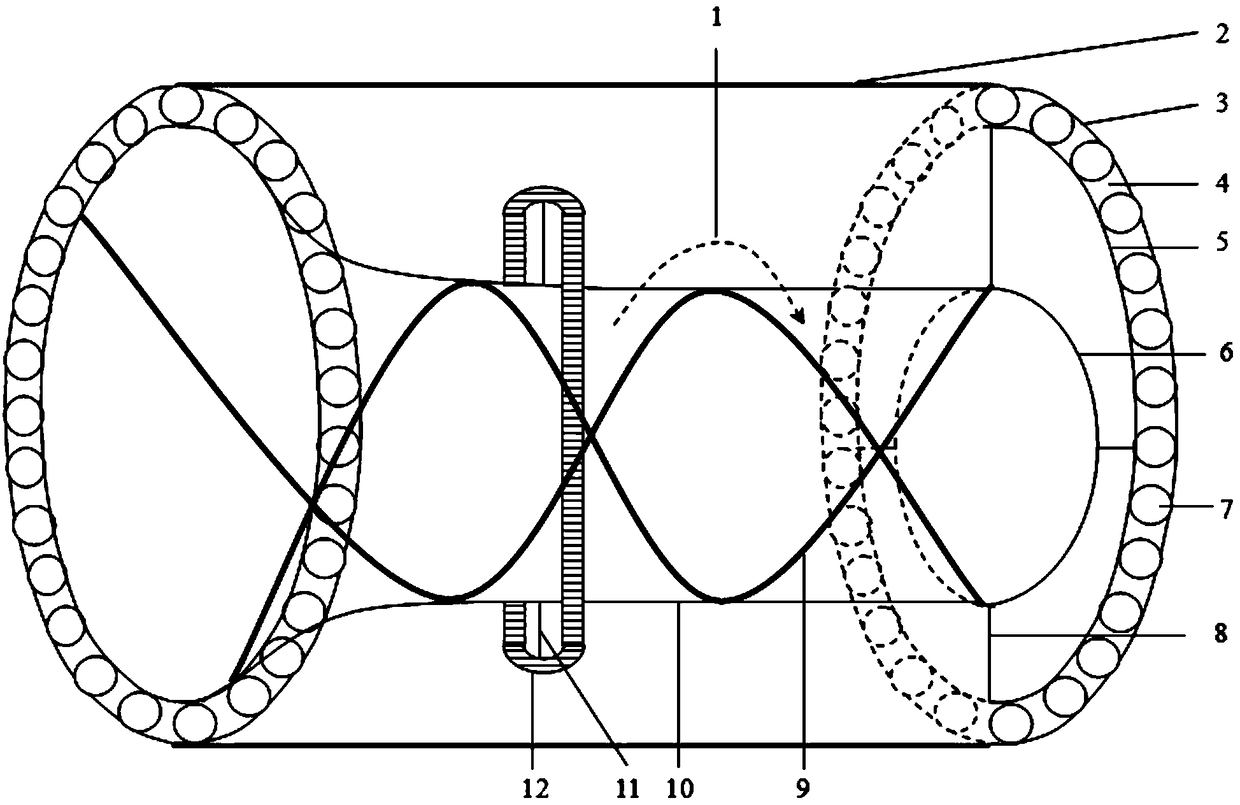

No-clogging pump with wall-attached rotating spiral impellers

A non-clogging pump and helical type technology, which is applied in the field of transportation of various fluids, non-clogging pumps, semi-fluids and solid-liquid mixtures, can solve problems such as winding, clogging, poor suction and lift, and achieve good non-clogging Performance, broad application prospects, and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Implementation example 1, using the pump of the present invention to pump and transport aquatic products such as live fish.

[0021] Take a special fish suction pump of the present invention, which has two symmetrical spiral impellers, which are symmetrically installed on the inner side of the pump main body, and are driven by a diesel engine through a reducer clutch and a pulley. The pump outlet diameter is 10 mm smaller than the inlet diameter Above, it is used for suction and conveying of fresh and live fish products in fish farms. Its function and model are determined as follows, assuming that the maximum length, width, and thickness of the fish body to be sucked are a, b, and c millimeters respectively, and their mutual relationship is a>b>c, then it is used to suck and transport fresh and live fish. For fish products, the outlet diameter of the pump in the present invention is >1.25bmm, the distance between the narrowest parts of the two spiral impellers is >1.25c...

Embodiment 2

[0022] Implementation example 2, using the pump of the present invention to pump and transport pulp thick pulp material.

[0023] Take a special suction pump of the present invention, which has two or four symmetrical spiral impellers, which are symmetrically installed on the inner side of the body wall of the pump body, and are driven by an electric motor through the clutch of the reducer and the transmission gear. The caliber is more than 10 mm smaller, and it is used for the transportation of pulp thick pulp materials, and the pulp concentration is less than 20%. According to the needs of the actual production situation, select and determine the relevant parameters of the pump of the present invention, such as suction lift, lift, caliber, water output, and matching motor power. Since there are no large particles in the pulp material, there are no relatively moving parts inside the pump of the present invention, which can be smoothly used for conveying dense pulp materials s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com