Oil extraction transition joint for transformer or reactor

A technology of transition joints and reactors, applied in the direction of pipes/pipe joints/fittings, instruments, sampling, etc., can solve the problems of oil sputtering working environment, dirt, oil sample pollution, etc., and achieve a clean and orderly working process. High promotional value, flexible and convenient to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

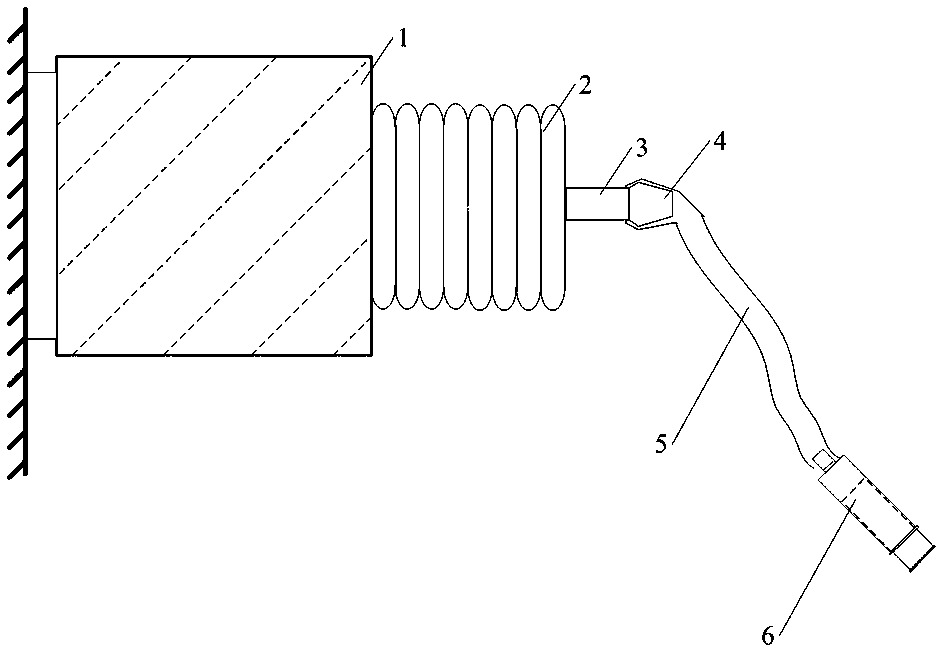

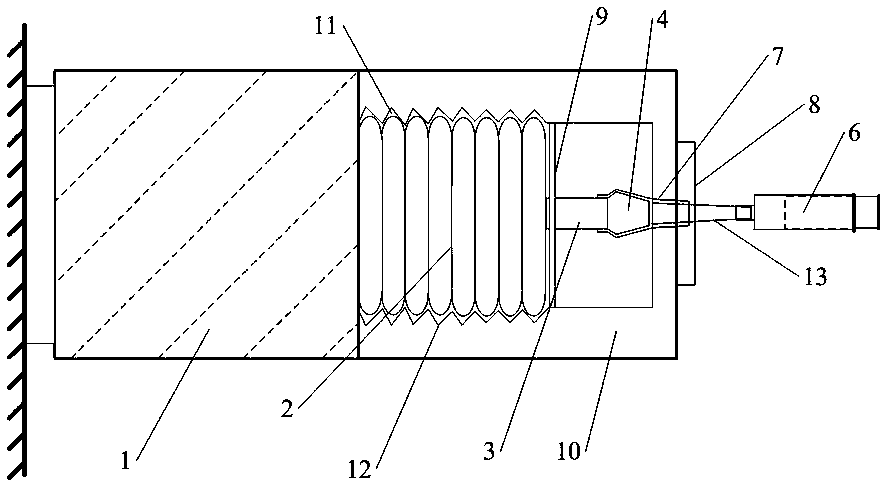

[0016] Such as figure 1 with 2 As shown, the present invention includes an oil extraction joint, and the oil extraction joint includes an oil outlet main valve 1, an oil extraction pipe 2 and an oil outlet head 3, and also includes a transition joint, and the transition joint is sleeved on the oil extraction port. On the joint; the transition joint includes a hollow cylindrical structure joint body 10 and a transition rubber sleeve 7 and a hard thin tube 13 arranged in the hollow cylindrical structure joint body 10, and the hollow cylindrical structure joint body 10 A connecting chamber 11 is provided on one side of the connecting chamber 11, and a joint engaging thread 12 is arranged on the inner wall of the connecting chamber 11; a reverse engaging thread is arranged on the outside of the oil taking pipe 2, and the reverse engaging thread and the connecting chamber The joint on the inner wall of 11 is matched with the thread 12; the inner end of the connection chamber 11 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com