Dry ice cleaning device and cleaning method thereof

A technology of dry ice cleaning and dry ice, which is applied in the field of cleaning and food hygiene, to achieve good cleaning effect, fast spraying speed and increased kinetic energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

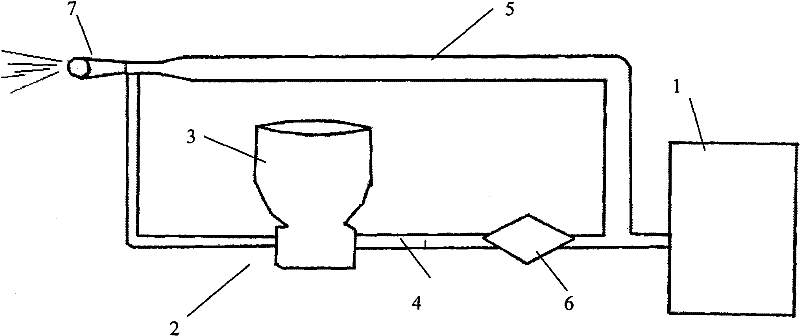

[0063] Such as figure 1 As shown, the dry ice blasting device of the present invention is a dishwasher, including an air compression system and an injection system connected thereto. A pipeline and a low-pressure gas pipeline. The low-pressure gas pipeline is provided with a material distribution mechanism and a pressure reducing valve. The high-pressure gas pipeline adopts a Venturi nozzle, and the air compression system communicates with the nozzle through the Venturi nozzle.

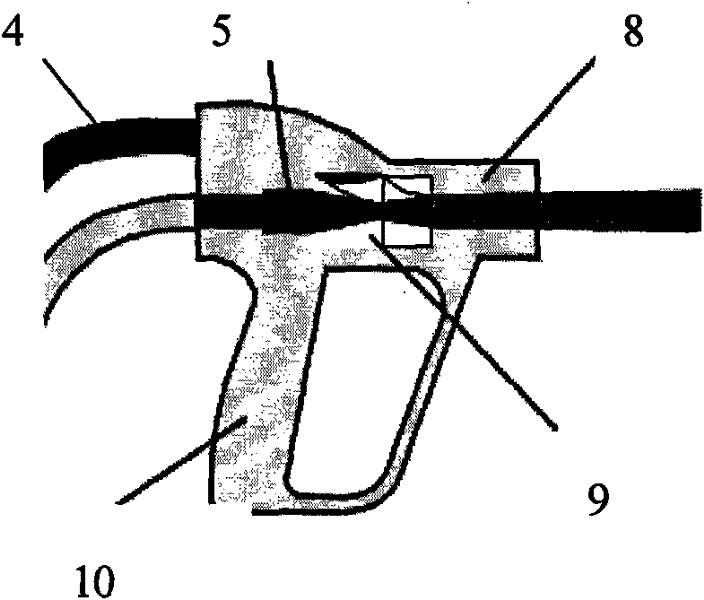

[0064] The outlet end of the material distributing mechanism communicates with the end of the Venturi nozzle of the air compression system and connects with the injection system. The diameter of the Venturi nozzle is 3-5mm.

[0065] The material distribution mechanism includes a dry ice material cylinder and a material distributor. The bottom of the cylindrical dry ice material cylinder in the material distribution mechanism is equipped with a material distributor, and is connected with a low-pressu...

Embodiment 2

[0077] Except for the following differences, it is the same as in Example 1, and a dry ice blasting device is prepared for dry ice blasting. The diameter of the Venturi nozzle is 4-6mm, and the pressure of the air compressor is 0.6MPa. The pressure of the high-pressure pipeline is set at 0.6MPa, and the pressure of the low-pressure pipeline is set at 0.16MPa. The Mach value of the jetting speed of the dry ice particles is 2.3-2.6, and the jetting amount of the dry ice particles from the nozzle is 38-40g per minute.

Embodiment 3

[0079] Except for the following differences, it is the same as in Example 1, and a dry ice blasting device is prepared for dry ice blasting.

[0080] The diameter of the Venturi nozzle is 7 mm, and the pressure of the air compressor is 0.7 MPa. The pressure of the high-pressure pipeline is set at 0.65MPa, and the pressure of the low-pressure pipeline is set at 0.20MPa. The Mach value of the jetting speed of the dry ice particles is 2.0-2.2, and the jetting amount of the dry ice particles from the nozzle is between 40-45g per minute.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com