Phase defect detection system and method based on short-phase dry-dynamic Twyman interferometer

A defect detection and interferometer technology, used in instruments, measuring devices, scientific instruments, etc., can solve the problems of inability to resist environmental disturbances, too strict distance requirements, and sparse distribution, achieve low environmental requirements, achieve dynamic measurement, high The effect of resolution detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

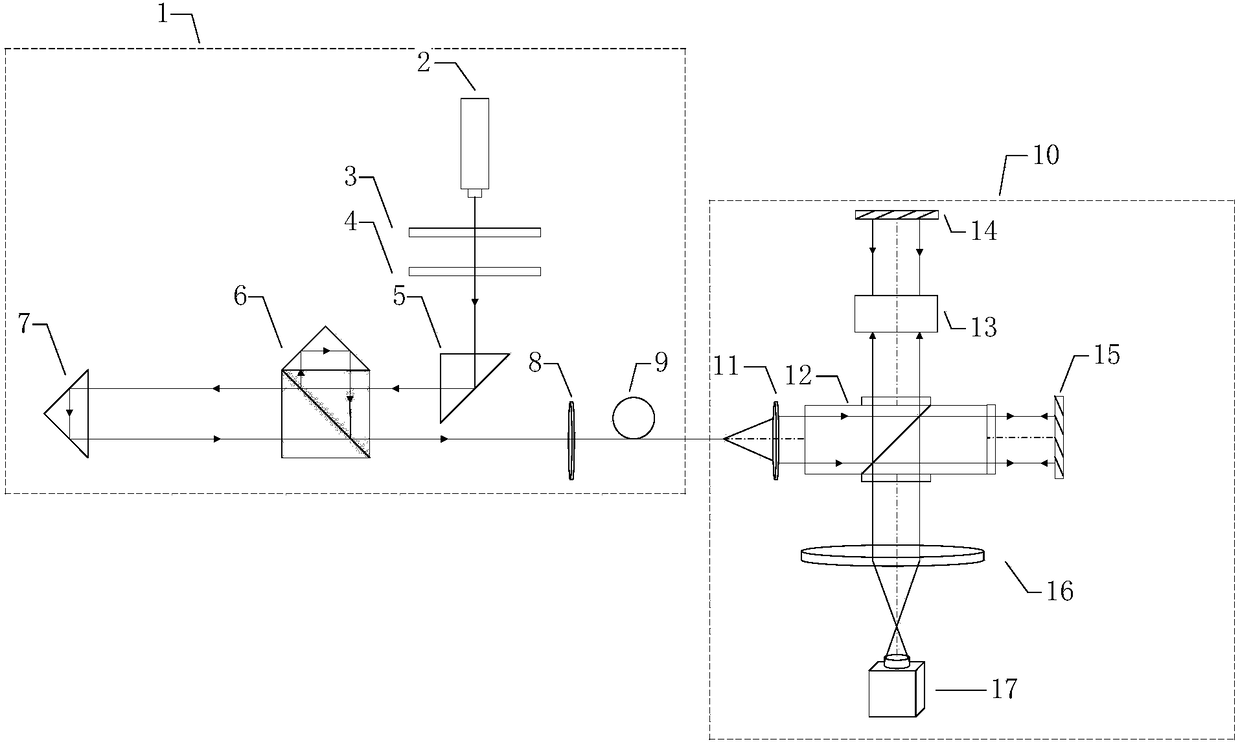

[0030] The optical path structure of the phase defect detection system based on the short coherent dynamic Tyman interferometer of the present invention is as follows: figure 1 shown, including:

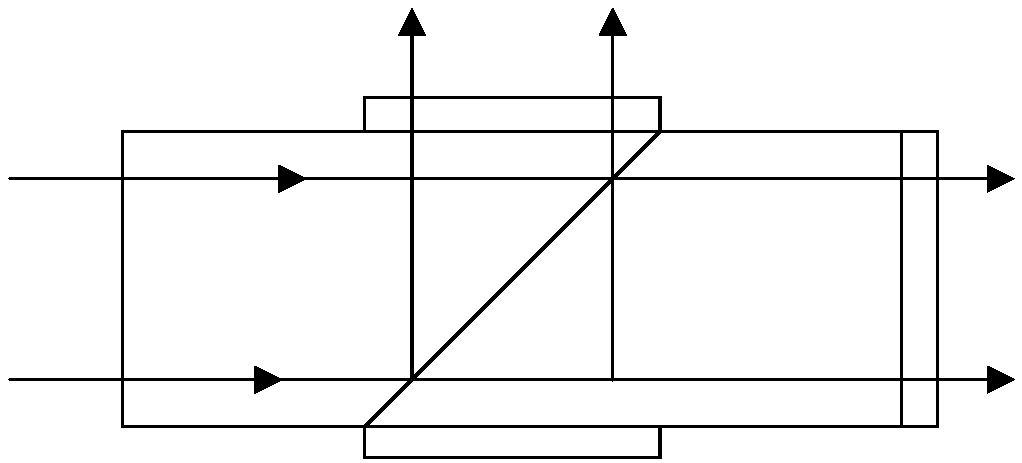

[0031] 1) The short coherent polarized light source 1 is used to generate a pair of linearly polarized lights with phase retardation and orthogonal polarization directions. The short coherent polarized light source 1 includes a short coherent laser 2 , a polarizer 3 , a half-wave plate 4 , a first pyramid 5 , a PBS pyramid glued 6 , a second pyramid 7 , and a coupling lens 8 , which are sequentially arranged on a common optical axis. and the polarization-maintaining fiber 9; the polarizer 3 and the half-wave plate 4 jointly generate polarized light, the PBS corner cone glue 6 reflects s light, and transmits p light, and the distance between the second corner cone 7 and the PBS corner cone glue 6 is Δ , the optical path difference between s light and p light is 2Δ and the polarizat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com