Brushless toothless inner brake motor

A brake motor and motor shaft technology, applied in the field of brushless and toothless internal brake motors, can solve the problems of complex structure, occupying the space of the whole vehicle, affecting the appearance of the whole vehicle, etc., to improve safety performance and convenience, prevent sliding or rear Slippery, beautiful and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

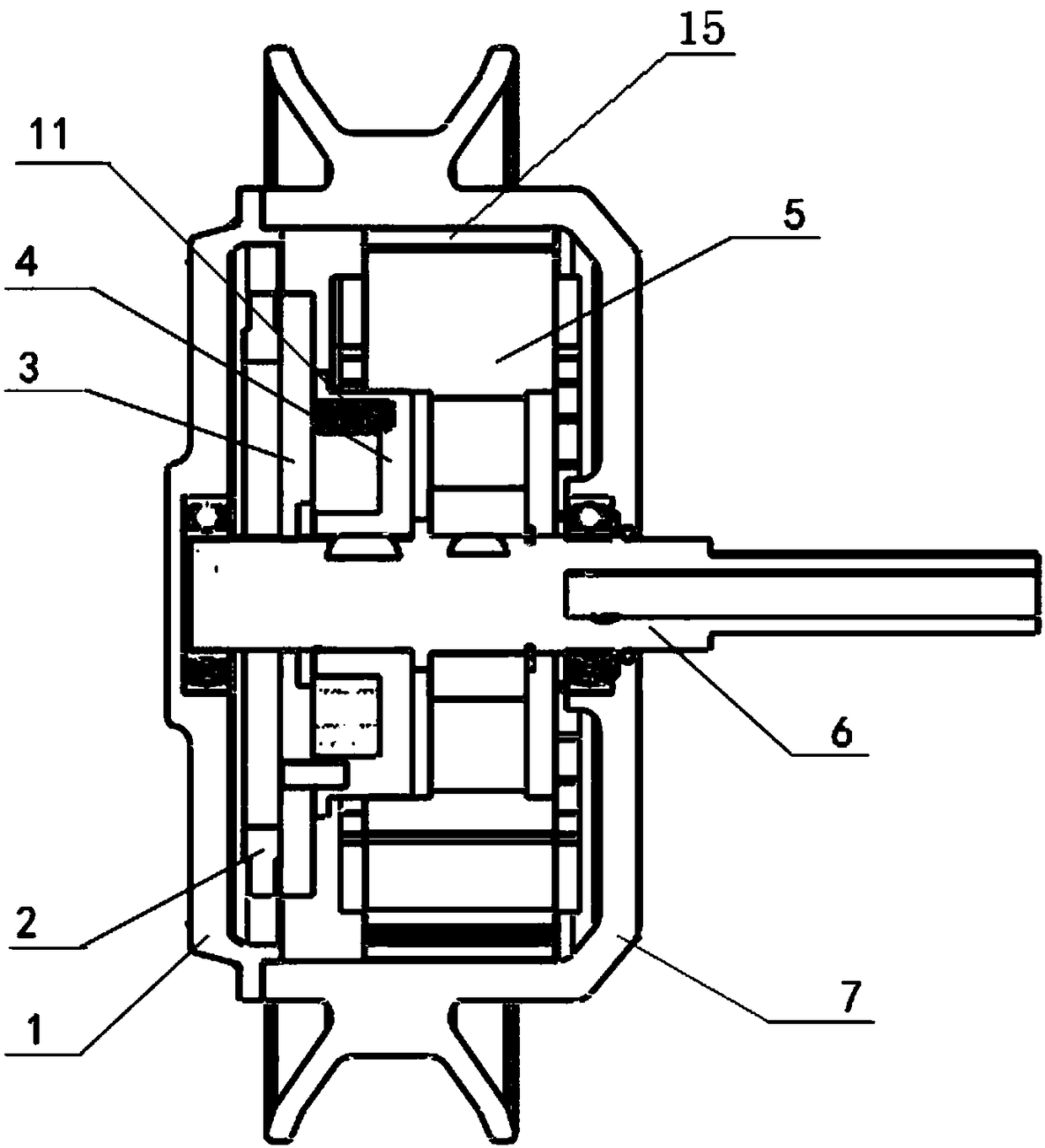

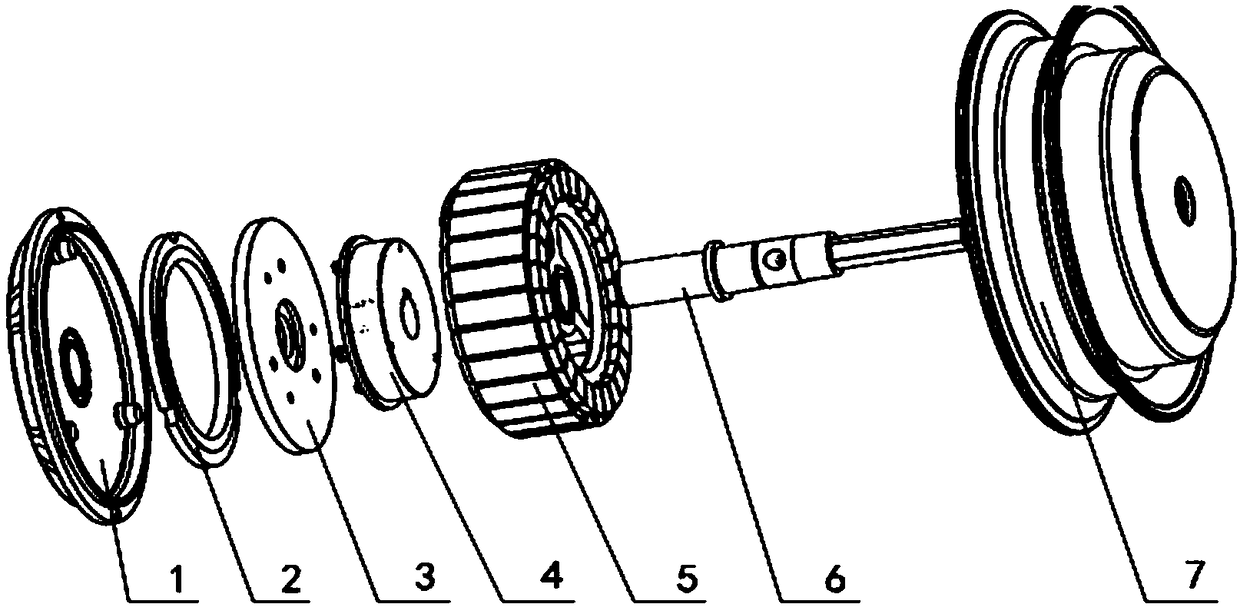

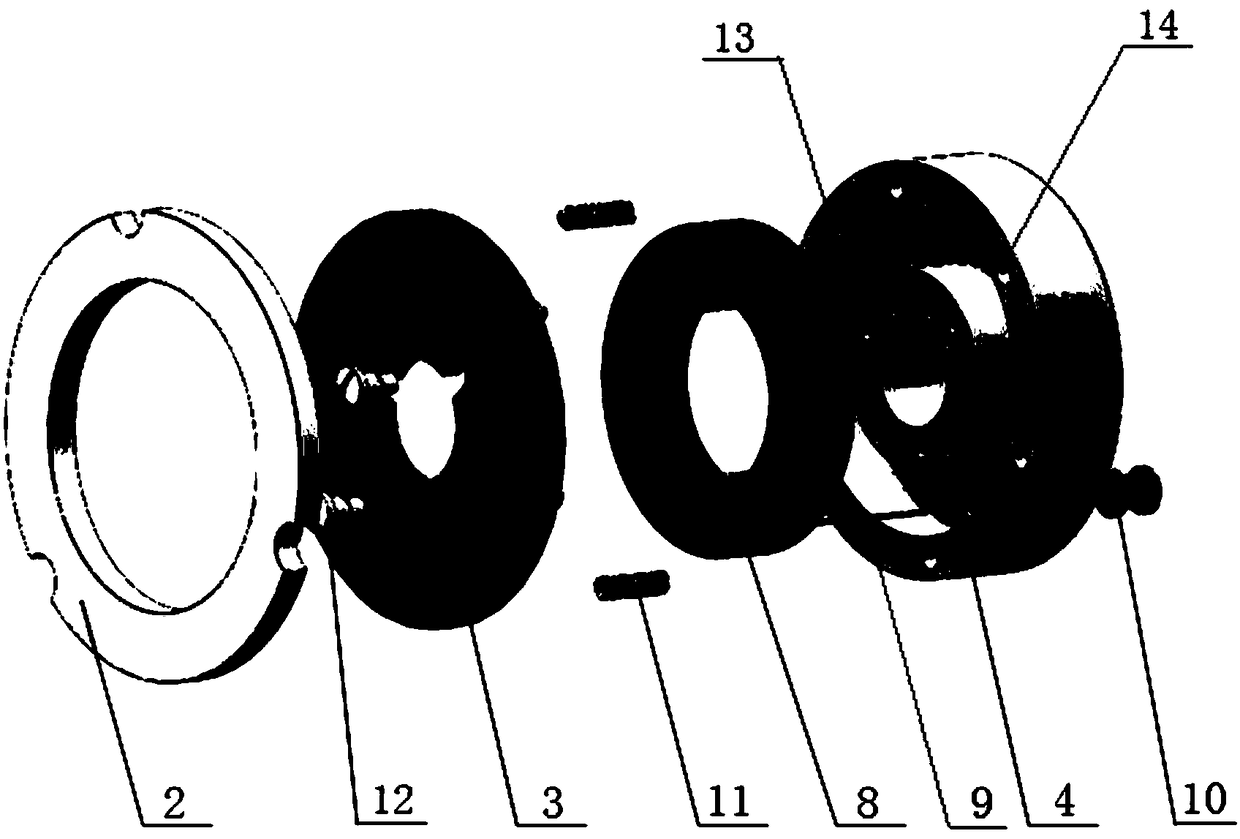

[0017] Example 1: A brushless toothless internal brake motor, such as figure 1 with figure 2 As shown, it includes a motor unit and a brake unit; the motor unit includes a motor shaft 6, a rotor set and a stator set 5, the rotor set includes a hub 7, an end cover 1, a magnet 15 and a bearing, and the brake unit includes friction Ring 2, moving piece 3 and magnetic brake seat 4.

[0018] The hub 7 is a motor housing, and the hub 7 is also a rotor at the same time. The inner circle of the hub 7 is uniformly pasted with magnetic steel 15. The hub 7 encapsulates the stator assembly 5, the magnetic brake seat 4, the rotor 3, and the friction ring 2 inside the hub 7 through the end cover 1. The outer circular groove of the hub 7 can be used for assembling tires.

[0019] The motor shaft 6 passes through the hub 7 and is rotatably fixed at the center of the hub 7 through bearings. The stator assembly 5, the magnetic brake seat 4, the rotor 3 and the friction ring 2 are all sleeved on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com