Fixing device used for simultaneously welding multiple locomotive drain pipes

A technology for drainage pipe fittings and fixing devices, which is applied in the field of fixing devices where multiple locomotive drainage pipe fittings are welded at the same time, can solve the problems of long processing period, unfavorable mass production, high processing cost, etc., to ensure elastic strength and long service life The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

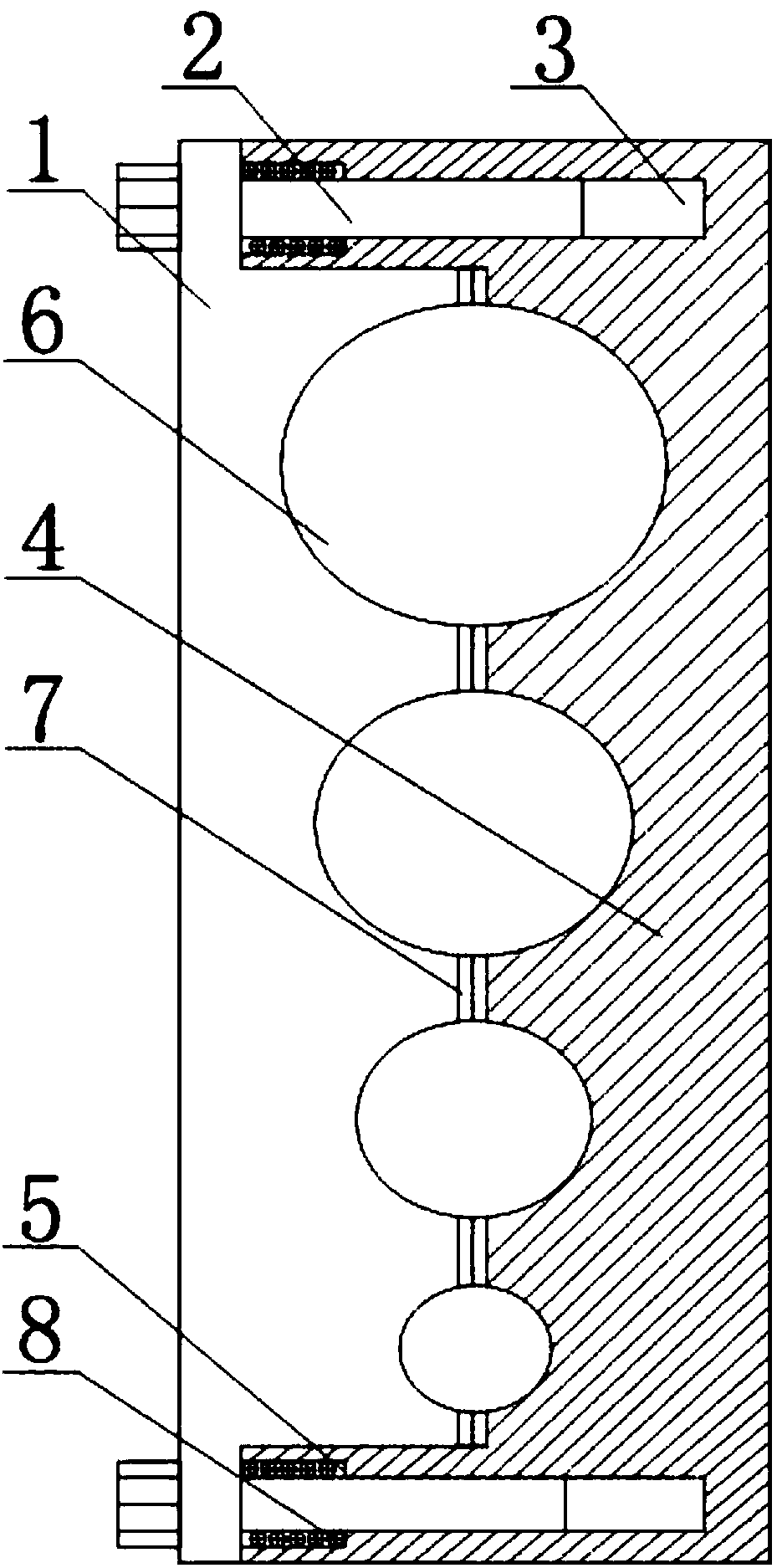

[0020] Such as figure 1 As shown, this embodiment includes a base plate 1 and a U-shaped fixing plate 4, fastening holes 3 are opened on the two vertical sections of the fixing plate 4, protrusions and bolts are respectively provided at both ends of the base plate 1 2. Movably go through the protrusions and cooperate with the fastening holes 3. On the side walls of the base plate 1 and the fixed plate 4, there are a plurality of semicircular grooves 6 with decreasing radii, and two semicircular grooves 6 with the same radius. Combined to form a complete clamping ring.

[0021] When working, the fixing plate 4 is installed on the welding workbench, the bolts 2 are out of contact with the fastening holes 3, and then the drainage pipes that need to be welded or cut are put into a plurality of semicircular grooves 6, and then the base plate 1 is embedded In the fixed plate 4, after the bolt 2 is centered with the fastening hole 3, turn the bolt 2 to make it fully fit with the fas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com