Stereolithography machine with inclined tank

A technology of three-dimensional lithography and printing presses, which can be used in manufacturing tools, processing platforms/substrates, processing driving devices, etc., and can solve problems such as unfavorable processing time and complex structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

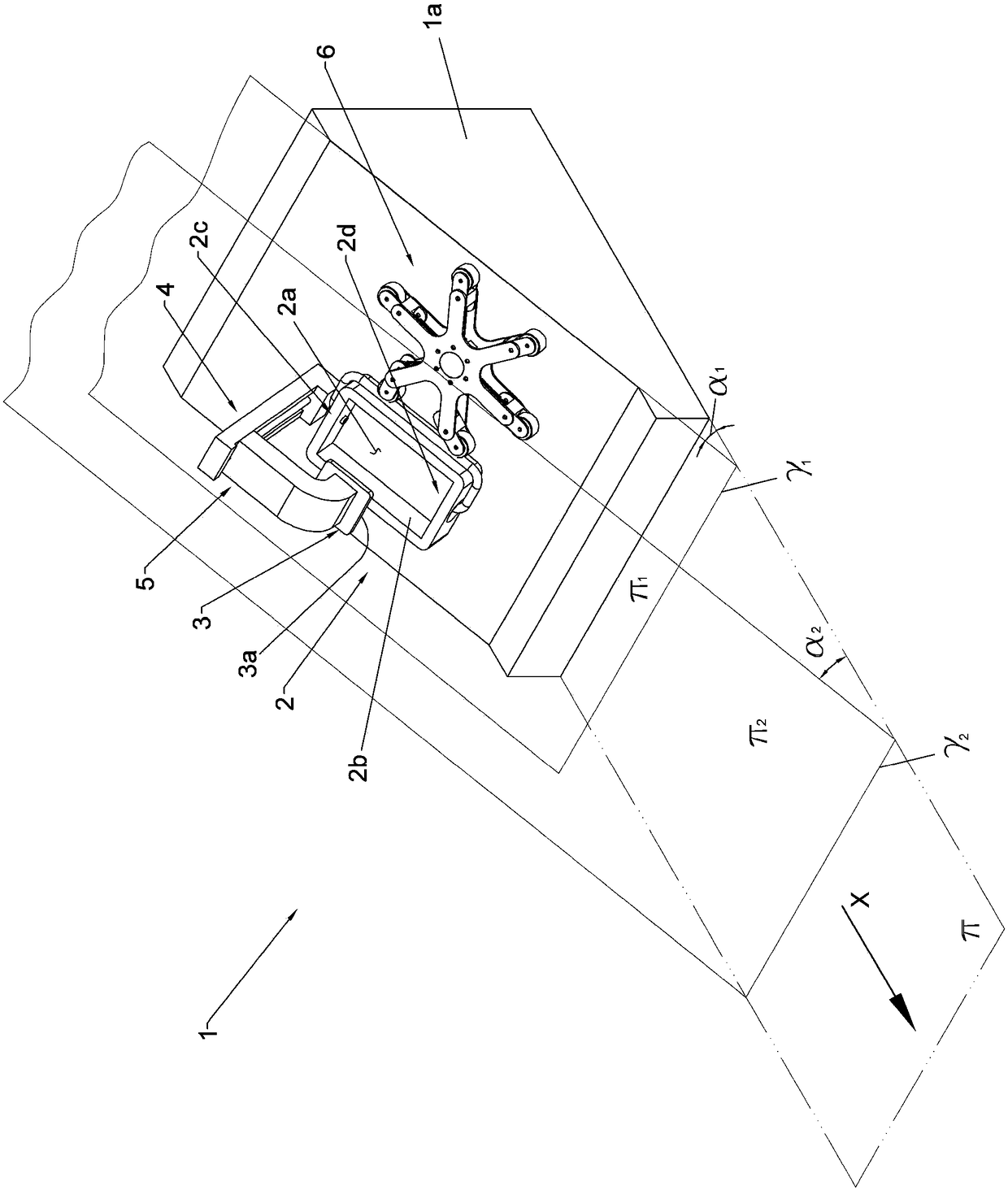

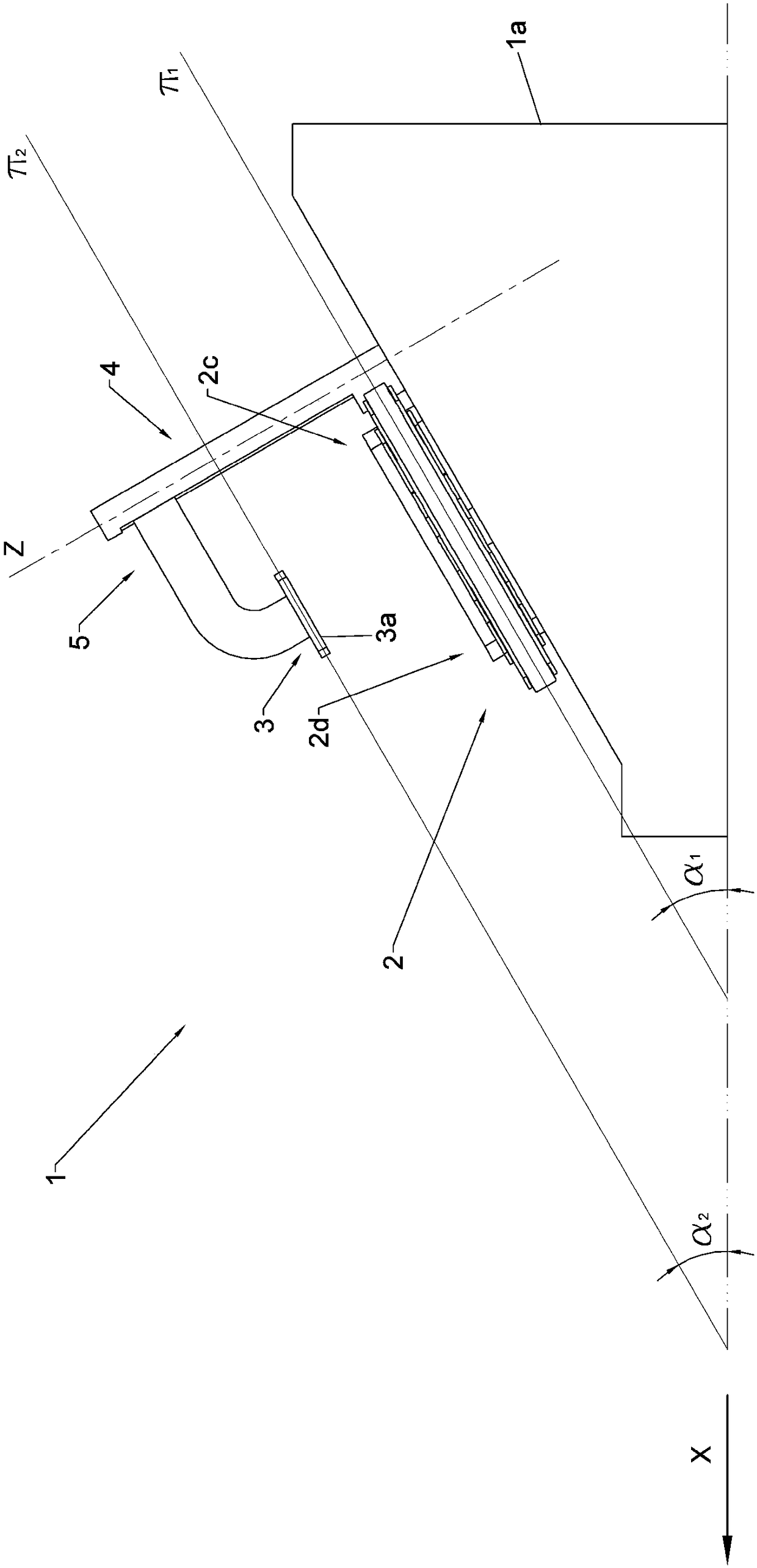

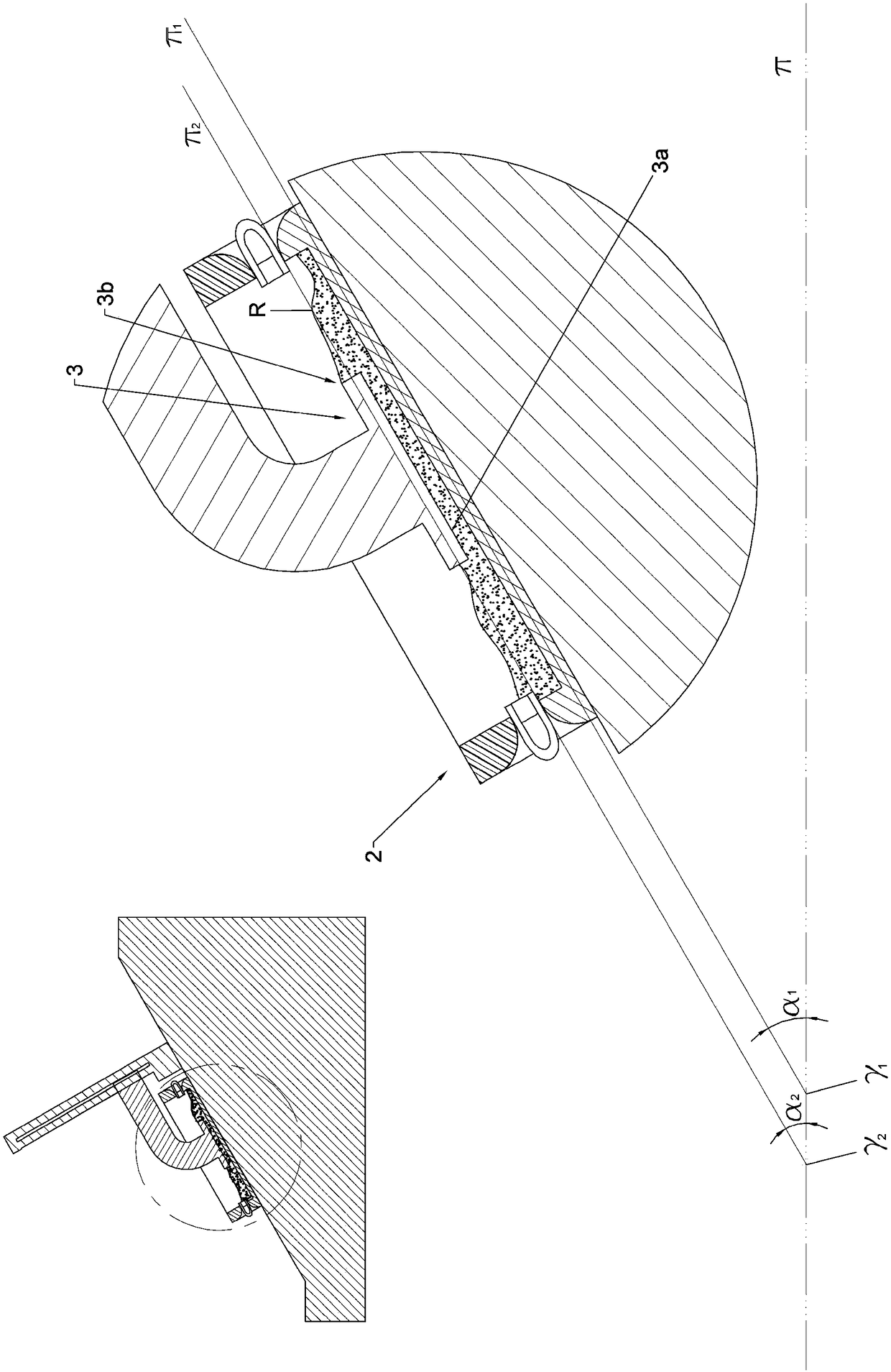

[0036] The stereolithography press of the invention according to a first preferred embodiment is shown in figure 1 and figure 2 , where the stereolithography machine is indicated by 1 as a whole.

[0037] As can be seen from such figures, the stereolithography machine 1 comprises a support structure 1a adapted to be placed on a substantially horizontal support plane π, such as for example the upper surface of a laboratory bench. As will become clear hereinafter, the reference direction X defined more precisely in the rest of the description is identified on the aforementioned support plane π.

[0038] Such a support structure 1a is configured to support a tank 2 provided with a bottom 2a and side walls 2b for containing a photosensitive liquid substance, preferably a photosensitive resin.

[0039] The bottom 2a is transparent in order to allow the passage of light beams from a light source, not shown in the figure but known per se, arranged below the box 2 . Such beams are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com