Controllable low-strength material

A low-intensity, raw-material technology, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., to achieve the effect of saving natural resources and reducing land occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] This embodiment provides a controllable low-strength material. In the ratio of raw materials, the sum of the mass of construction spoil, recycled fine aggregate of construction waste and fly ash is M, wherein the mass of fly ash is 20%. *M, the quality of recycled fine aggregate of construction waste is 75%*M, the quality of construction spoil is 5%*M, the quality of cement is set to 8%*M, and the quality of added water is 24%*M.

[0026] The preparation method of the controllable low-strength material is as follows:

[0027] During the stirring process, control the stirring speed of the mixer to 445-460r / min; first add water with a mass of 24%*M, then add construction spoil with a mass of 5%*M, and stir for 5 minutes; then add 20% *M of fly ash and 75%*M of construction waste regenerated fine aggregate, and then stir for 5 minutes; finally add cement with a mass of 8%*M, and continue to stir for 5 minutes to obtain a CLSM mixture. The fluidity of the obtained CLSM mix...

Embodiment 2-3

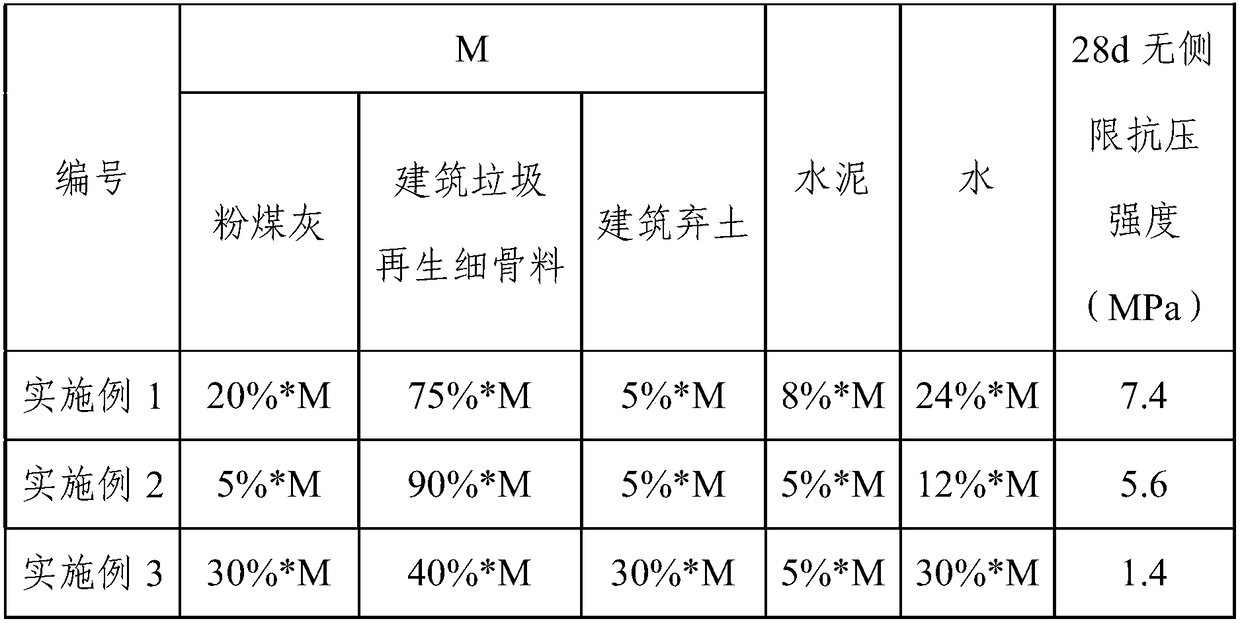

[0029] Embodiment 2-3 and embodiment 1 identical raw material and steps are all identical, and difference is only in the quality ratio of construction spoil, construction waste regenerated fine aggregate, fly ash, cement and water, concrete mixing ratio and the CLSM that obtains The basic performance is shown in Table 1:

[0030] Table 1 Proportion of different fly ash, recycled fine aggregate from construction waste, construction spoil, cement and water

[0031]

[0032] Among them, M is the sum of the mass of construction spoil, recycled fine aggregate of construction waste and fly ash. During the proportioning process, the sum of the mass of construction spoil, recycled fine aggregate of construction waste and fly ash is generally fixed, and the mass ratio of construction spoil, recycled fine aggregate of construction waste, fly ash, cement and water is adjusted.

[0033] Wherein, embodiment 1 is the situation of the mass ratio of construction spoil, construction waste ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com