Repelling robot for feeding in intelligent pasture

A robot and pasture technology, applied in the field of intelligent robots, can solve the problems of increasing labor costs, negative dairy output, and single function, and achieve the effects of improving production efficiency, reducing labor intensity, and overcoming high labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes.

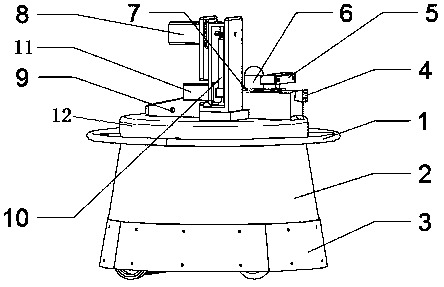

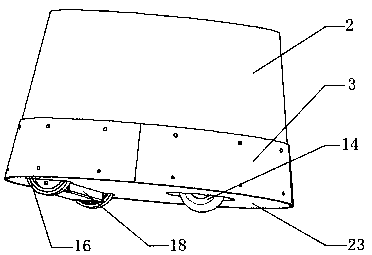

[0027] Such as figure 1 An intelligent ranch raising and driving robot is shown, including a walking device, and a rotating casing 2 installed on the walking device and driven to rotate by the driving device I. The outer side of the shell 2 is fixed with a pushing plate 3, and the top of the rotating casing 2 is provided with a top cover 12 driven by the driving device I to rotate, and the top cover 12 is provided with a livestock detection device, and is connected with the said top cover 12. The driving device electrically connected to the livestock detection device, the walking device, the driving device I, the livestock detection device and the driving device are all electrically connected to the master controller.

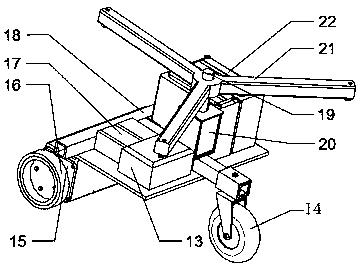

[0028] The running gear comprises a frame 18 and a universal wheel 14 and two driving wheels 16 which ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com