Full-automatic drink machine

A beverage machine, fully automatic technology, applied in beverage preparation devices, home appliances, applications, etc., can solve the problems of waste of time and experience of production personnel, low degree of automation, differences, etc., to achieve stable and reliable quality of finished products, improved degree of automation, and guaranteed The effect of normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

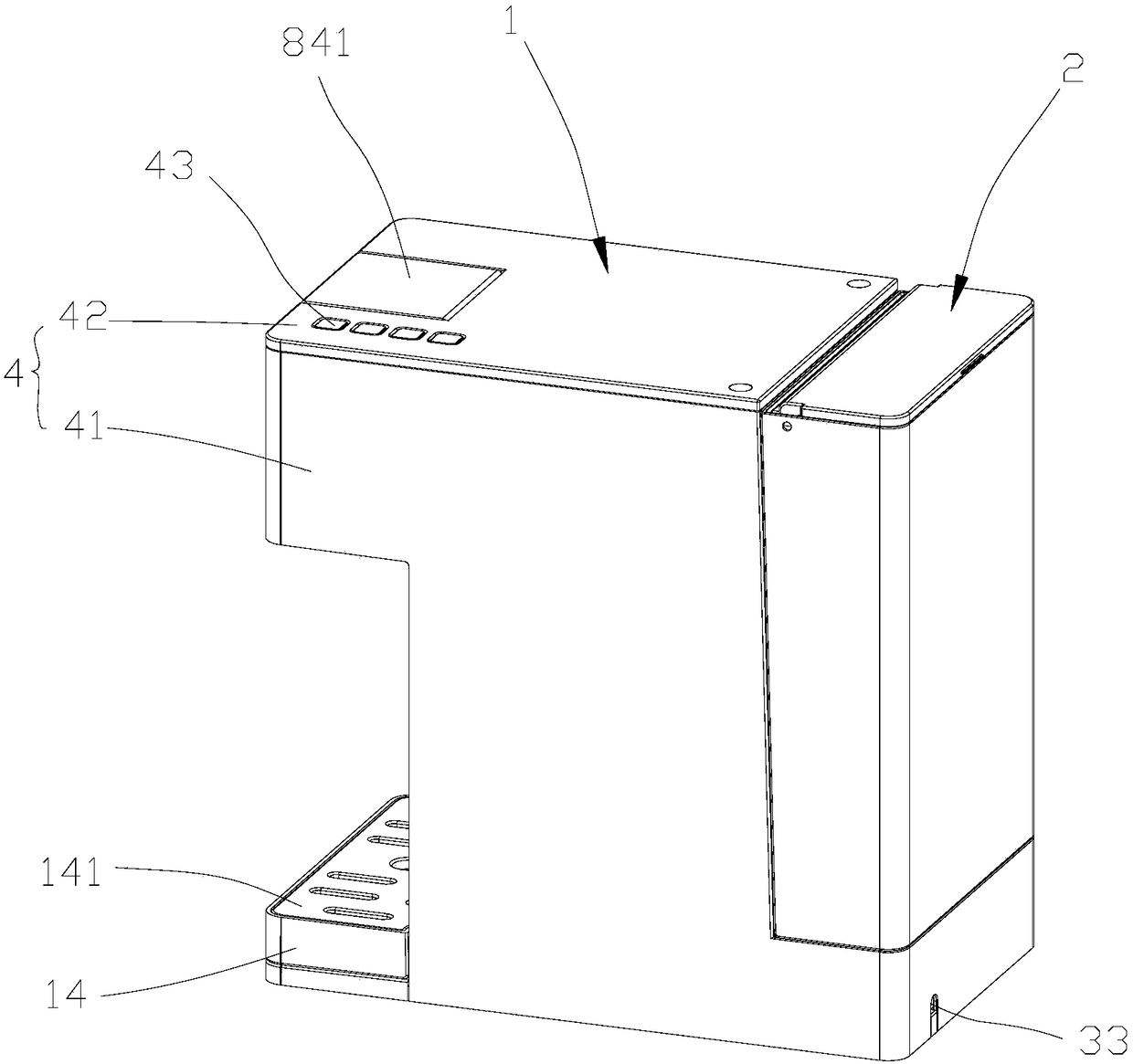

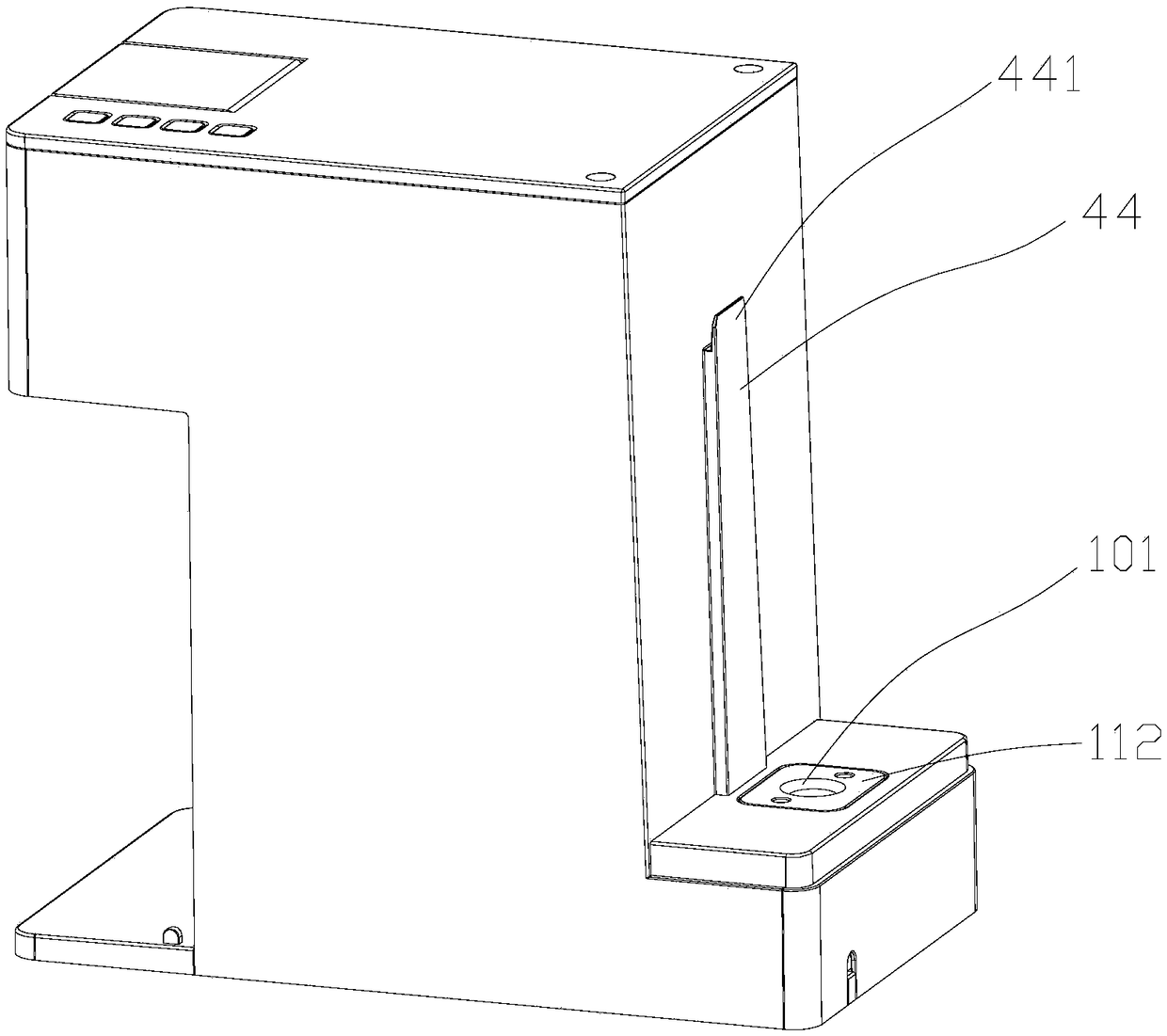

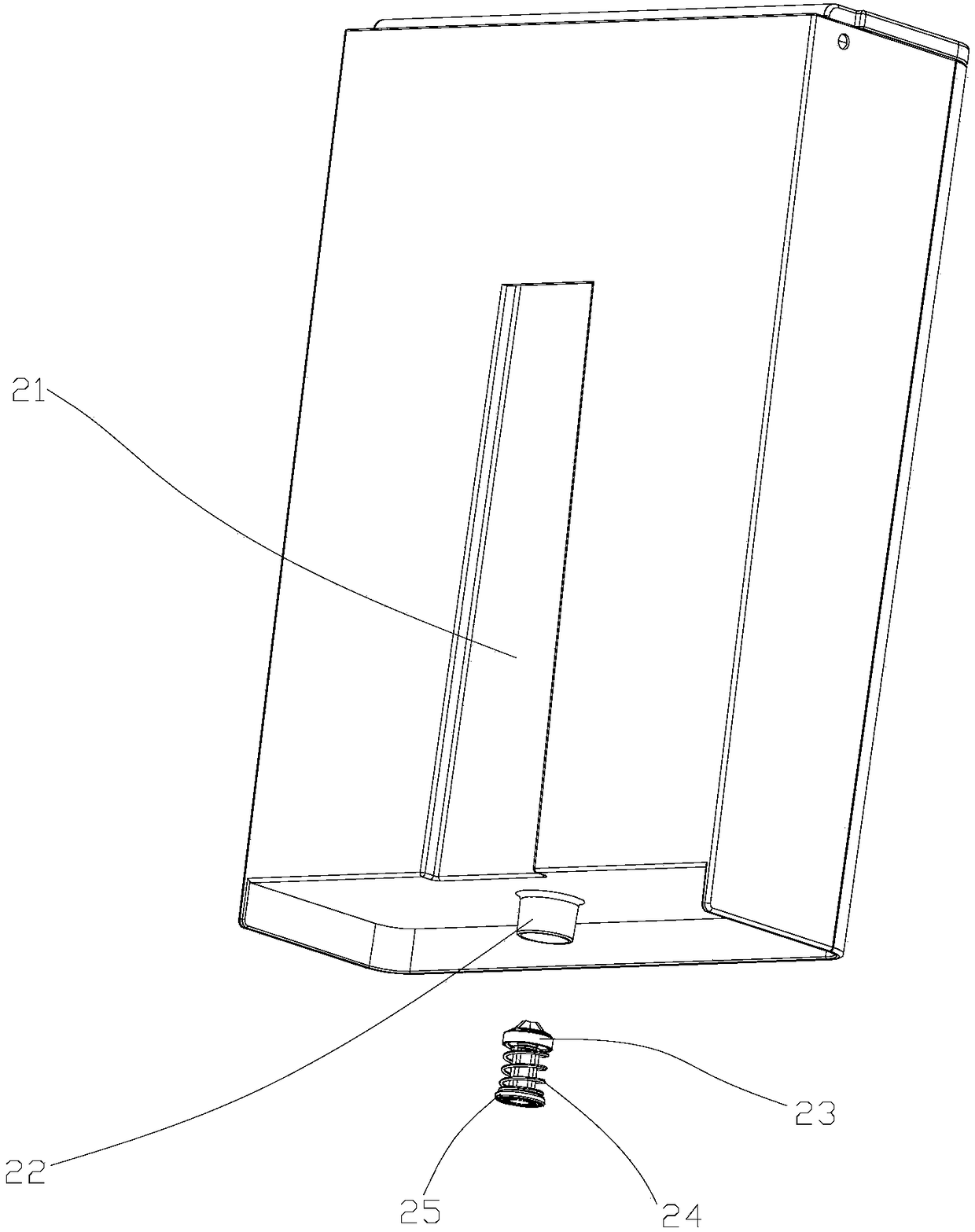

[0048] refer to figure 1 , Figure 4 with Figure 5 , a fully automatic beverage machine provided by the present invention includes a main body 1 and a water tank 2, the main body 1 includes a mounting frame 3, a casing 4, an electromagnetic pump 5, a heating boiler 6, an air pump 7, an extraction mechanism 8 and a circuit control module 9 , the water tank 2 is installed behind the main body 1, and is used to provide drinking water to the main body 1; one end of the electromagnetic pump 5 is connected to the water tank 2, and the other end is connected to the boiler water inlet 62 of the heating boiler 6, and the boiler outlet of the heating boiler 6 The water port 64 is connected to the extraction mechanism 8 through a two-inlet and one-outlet three-way valve 12, the water outlet of the heating boiler 6 is connected to the first inlet 121 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com