Multi-hole tantalum rod device

A technology of porous tantalum and protective tubes, applied in bone implants, joint implants, joint implants, etc., can solve problems such as knocking off tantalum rods, and achieve integrity, stability, and increased firmness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

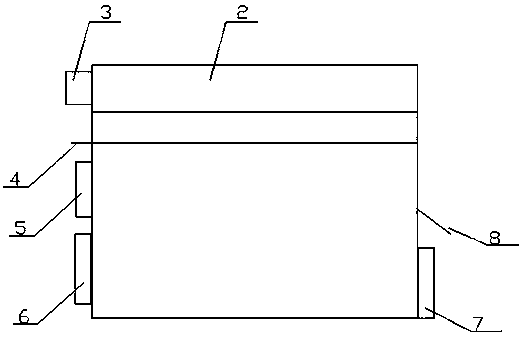

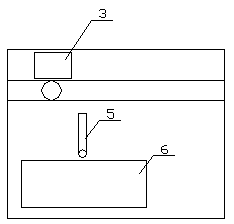

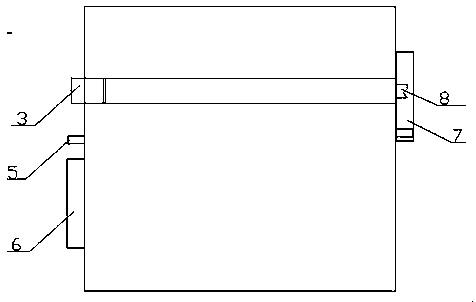

[0025] Such as Figure 1 to Figure 13 As shown, a porous tantalum tantalum rod device includes a tantalum rod 1-1, which is characterized in that: the tantalum rod device includes a protection tube 1-2 for accommodating the tantalum rod, and the side wall of the protection tube is provided with a concave Pit 1-3, conical protrusion 1-4 is provided in the pit, the top of the conical protrusion is flat with the outer surface of the inner wall, and the protective tube is made of rigid elastic material.

[0026] When in use, put the protection tube into the drill hole first, and then insert the tantalum rod into the protection tube. The protection tube is firmly fixed in the borehole by pressing against the inner wall of the borehole. In this way, the protection tube can protect the tantalum rod from being squeezed, and at the same time, it has b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com