Processing tank for dried earthworm product

A processing box and earthworm technology, applied in drying, drying machine, local mixing and drying machine, etc., can solve problems such as troublesome drying and processing, complicated operation, waste of manpower and material resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

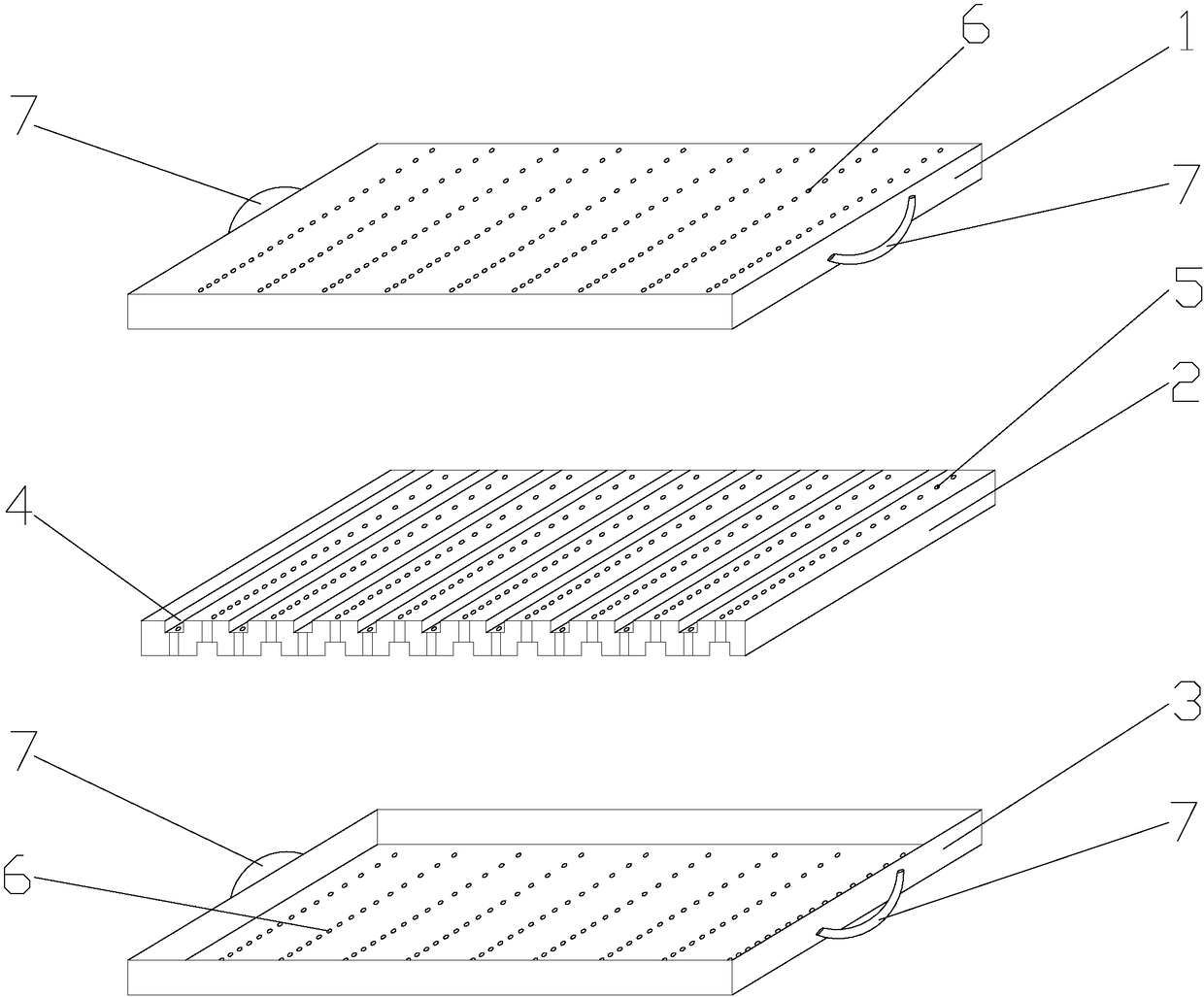

[0014] Such as figure 1 What is shown is a processing box for dry earthworm products, which is mainly composed of an upper cover 1, an earthworm storage cavity 2 and a lower cover 3; the upper surface and the lower surface of the earthworm storage cavity 1 are provided with multiple parallel grooves 4 , the grooves 4 on the upper surface and the grooves 4 on the lower surface are arranged in a staggered manner, and a plurality of through holes 5 are arranged on the grooves 4 .

[0015] Wherein the size of the through hole 5 is smaller than the outer body size of the molded live earthworm. The depth of groove 4 is the thickness of molding living earthworm. The upper cover 1 and the lower cover 3 are also provided with exhaust holes 6 corresponding to the through holes on the earthworm housing cavity. Both sides of the upper cover 1 and the lower cover 3 are provided with handles 7 .

[0016] Operating procedures:

[0017] Just place the live earthworms on the upper surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com