Flat stitching sewing machine umbrella cloth auxiliary traction tensioning frame

A technology for auxiliary traction and sewing machines, applied to sewing machine components, sewing equipment, cloth feeding mechanisms, etc., can solve the problems of high labor cost and high labor intensity, and achieve the effect of simple structure and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

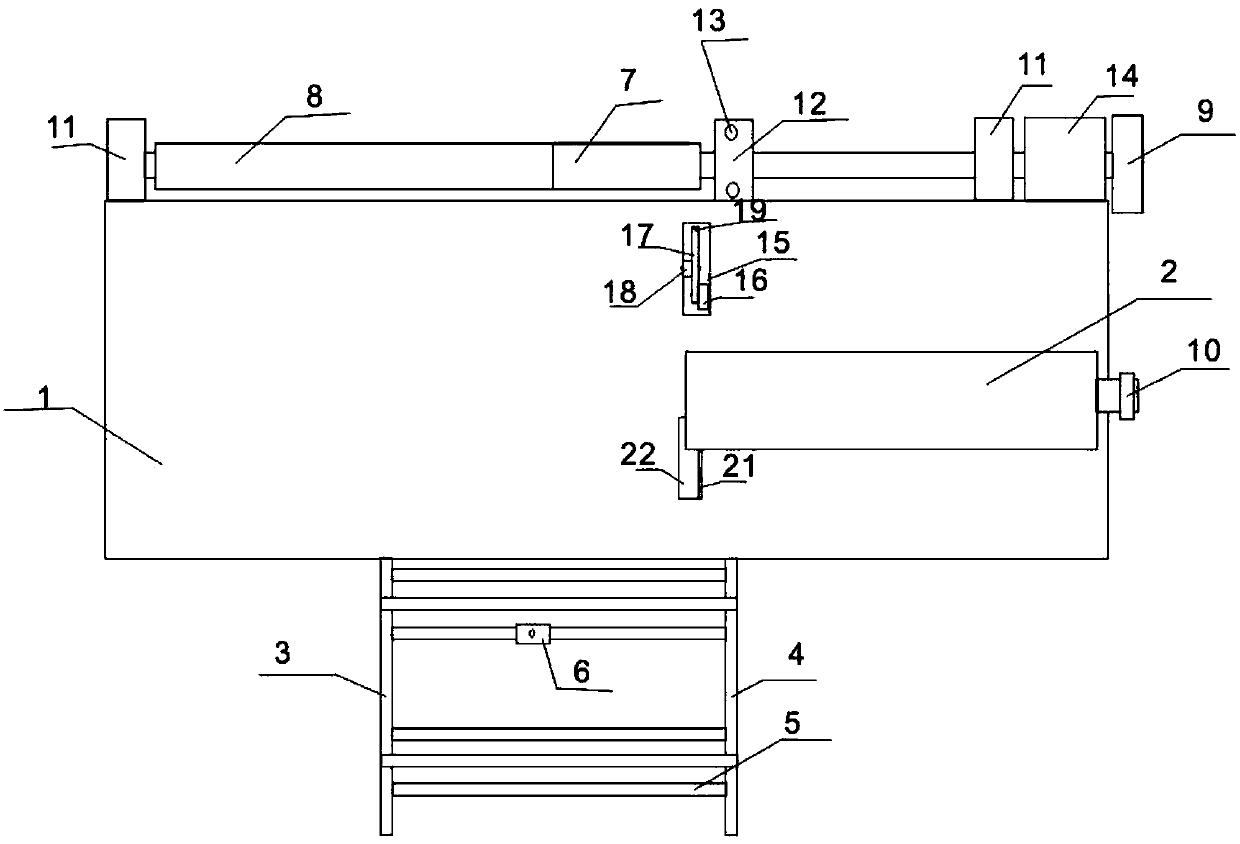

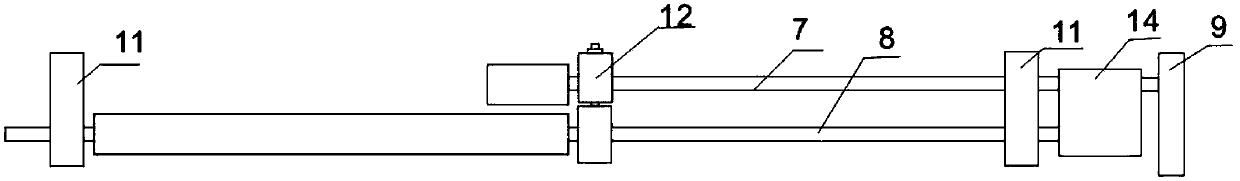

[0017] Such as Figure 1-4 The shown flat car sewing machine is composed of a frame 1, a sewing machine body 2, an auxiliary traction tensioning frame, an umbrella cloth deviation detection device, an umbrella cloth traction device and an umbrella cloth pressing device.

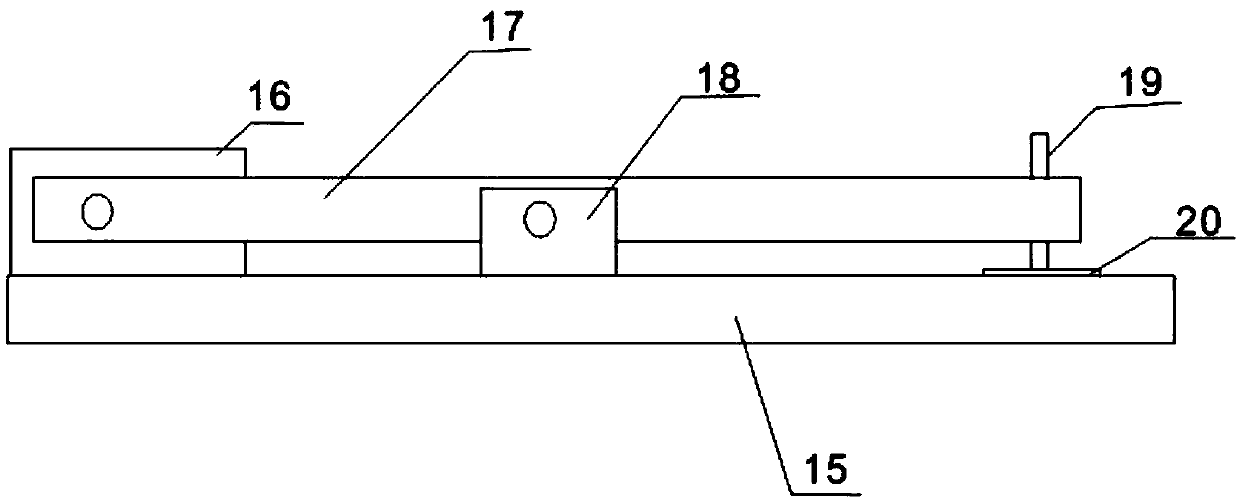

[0018] The structure of the sewing machine body 2 is prior art, so it will not be repeated here. The front side of the working table of the frame 1 is provided with an auxiliary traction tensioning frame that allows the umbrella cloth to be laid flat on it, the rear side is provided with an umbrella cloth traction device, and an umbrella cloth runner is provided behind the sewing needle of the working table. Bias detection device. On the working table, an umbrella cloth pressing device is arranged in front of the sewing needle of the sewing machine.

[0019] Wherein: the auxiliary traction tensioning frame includes a left bracket 3 and a right bracket 4, at least two groups of steel pipes 5 are arranged bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com