Waste gas treatment device of electrochemical aluminum coating machine

The technology of a waste gas treatment device and a coating machine, which is applied in the field of machinery, can solve the problems of high operation cost, waste gas generation, and waste gas cannot be recycled, and achieves the effects of compact shape and structure, high filtration stability and high practical value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

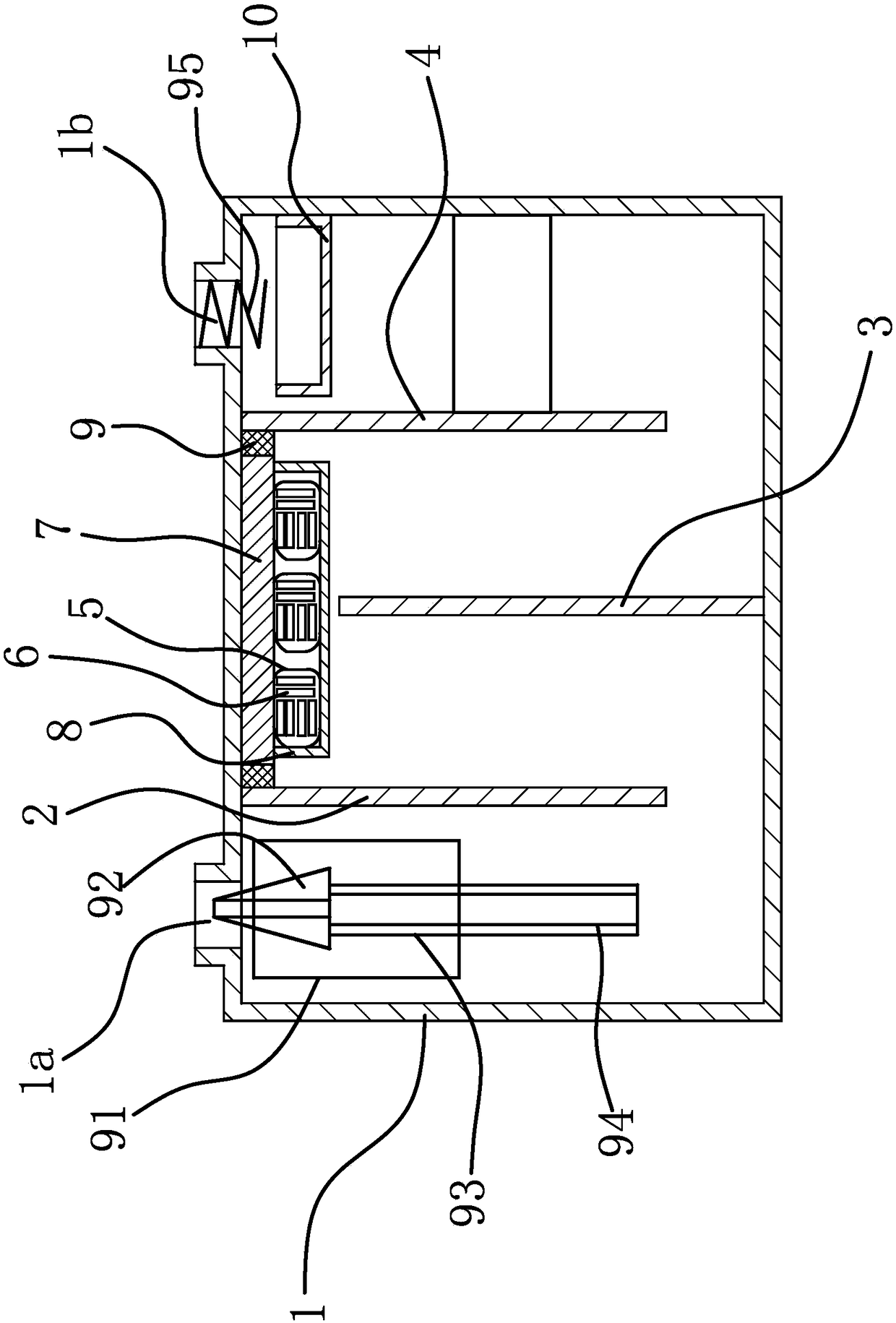

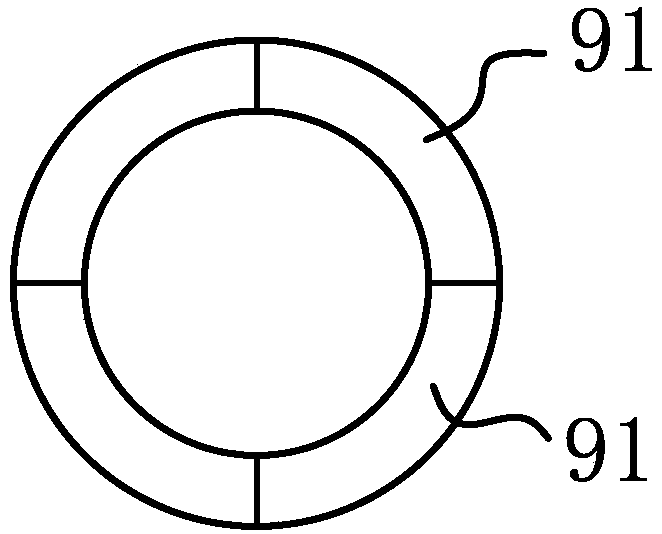

[0035] Such as Figure 1-2 As shown, the exhaust gas treatment device of the anodized aluminum coating machine includes a housing 1 with a cavity inside, and the housing 1 has three partitions: partition one 2, partition two 3 and partition three 4, The above-mentioned partition two 3 is located between the partition one 2 and the partition three 4, and the lower end of the partition two 3 is fixedly connected to the bottom of the housing 1 and forms a vent two between the upper end of the partition two 3 and the housing 1, The upper end of the above-mentioned partition one 2 is fixedly connected to the top of the casing 1 and a vent one is formed between the lower end of the partition one 2 and the casing 1, and the upper end of the above-mentioned partition three 4 is fixedly connected to the top of the casing 1 and on the top of the partition three 4 A vent three is formed between the lower end and the housing 1. The housing 1 also has an inlet 1a and an outlet 1b communica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com