Antihypertensive drug production equipment

A production equipment and anti-hypertensive technology, applied in chemical/physical processes, dissolution, mixers, etc., can solve the problems of affecting drug efficacy, single stirring direction, and poor mixing quality, so as to improve mixing efficiency, improve mixing quality, The effect of increasing the relative rotational speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

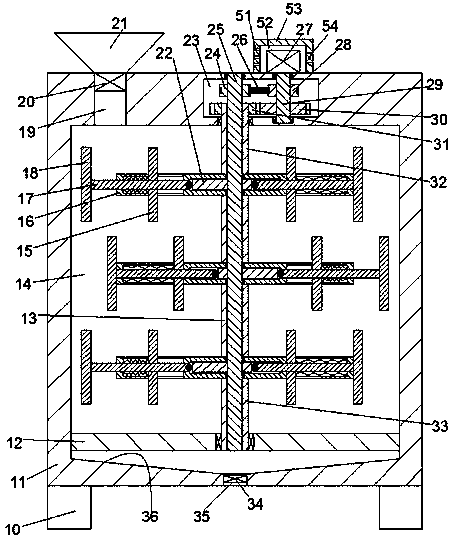

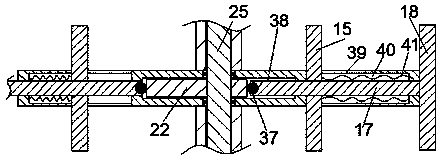

[0015] Such as Figure 1-Figure 2 As shown, a kind of antihypertensive drug production equipment of the present invention comprises a mixing cylinder 11, a bracket 10 is fixedly installed at the lower end of the mixing cylinder 11, a mixing chamber 14 is arranged in the mixing cylinder 11, and the bottom of the mixing chamber 14 is The center of the wall is provided with a discharge trough 35 communicating with the outside, the left side of the top wall of the mixing chamber 14 is provided with a feed tank 19 communicating with the outside, and a transmission chamber 23 is also provided in the top wall of the mixing chamber 14, so The lower part of the mixing chamber 14 is fixedly equipped with a support rod 12, and a mixing assembly is arranged in the mixing chamber 14. The mixing assembly includes a central shaft 25 extending up and down, and a plurality of stirring arms are rotatably installed on the central shaft 25. 16. A connecting sleeve 13 is fixedly installed between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com