Miscellaneous paint avoiding device for automobile priming paint coating and miscellaneous paint avoiding method applying miscellaneous paint avoiding device

A primer and coating technology, which is applied in the field of automobile coating equipment and the application of the equipment, can solve the problems of production efficiency, production quality and cost control, increase the difficulty of cleaning, and cumbersomeness, etc. The effect of the probability of miscellaneous paint, reducing the number of replacements, and rational use of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

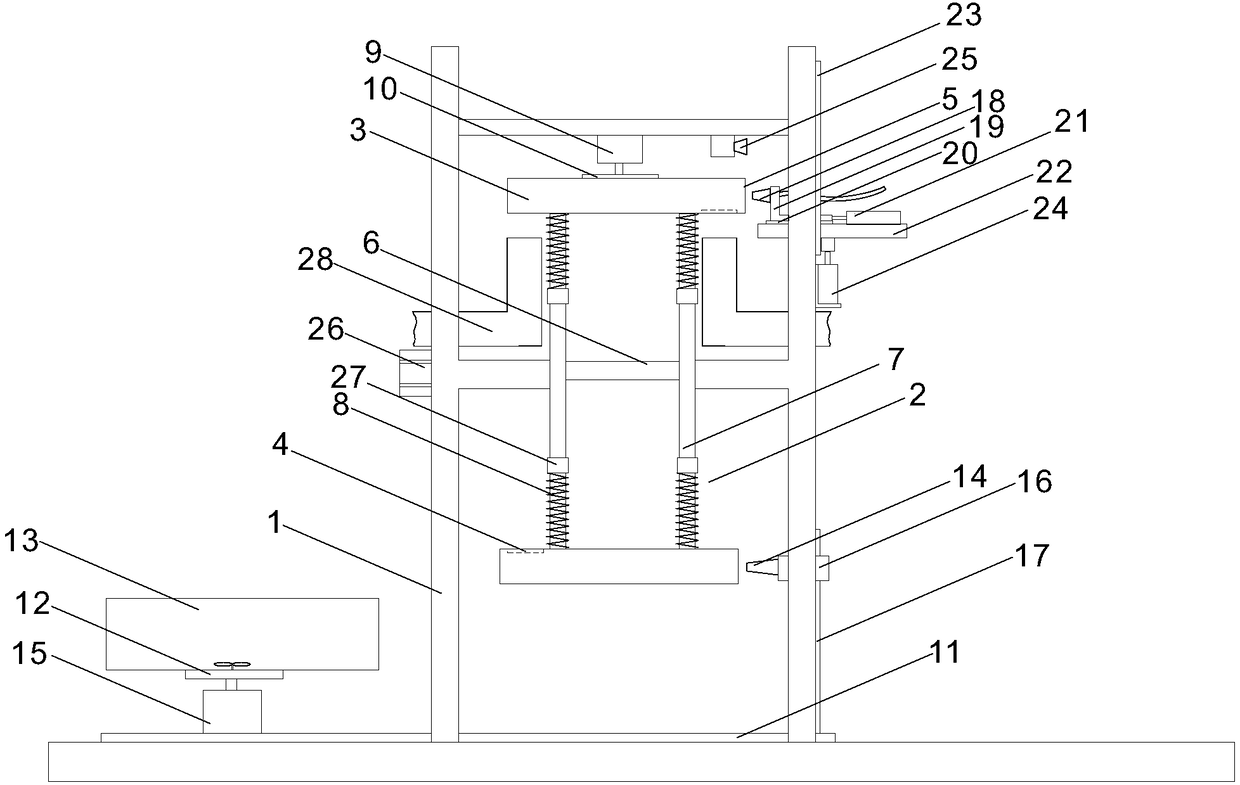

[0026] Such as figure 1 Shown, a kind of car coating primer avoids miscellaneous paint device, is located at the intersection of the paint transmission and mixing pipeline 28 of each color primer, at the intersection, the transmission and mixing paint pipeline 28 of each color primer is parallel upwards, and each color primer The paint transmission and mixing pipelines 28 are all fixed by fixed mounts, so that the paint transmission and mixing pipelines 28 of various colors of primers possess higher external pressure bearing capacity. The car paint primer and miscellaneous paint avoidance device includes a frame 1, a rotating frame 2 and two parallel alternate interchange pipes 3, and the rotating frame 2 is rotatably connected to the frame 1 and is connected to a driving device. The driving device is a Swing cylinder 26, the swing range of swing cylinder 26 is 180 °. The alternate junction pipe 3 is connected to the outer edge of the rotating frame 2, and the alternate junct...

Embodiment 2

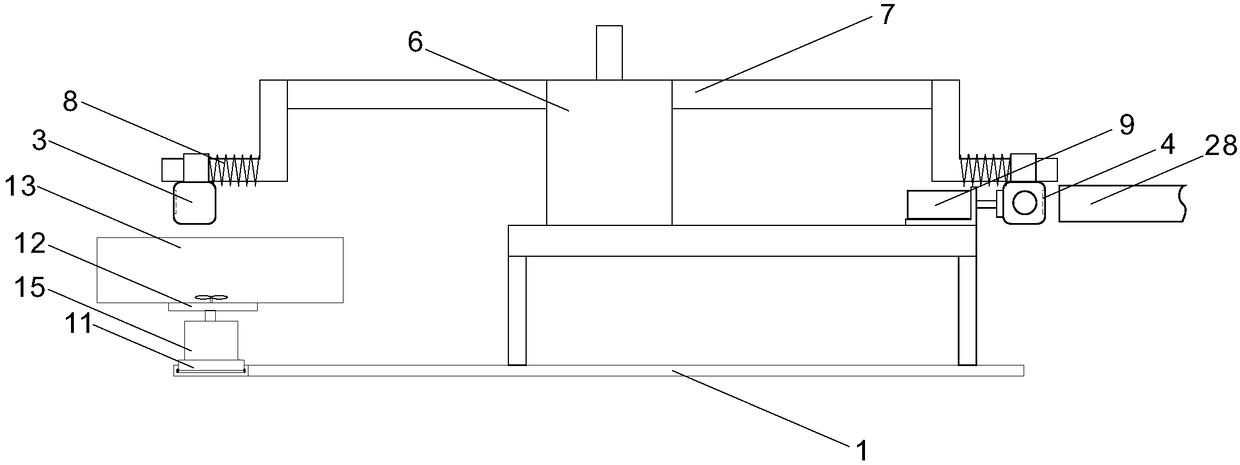

[0033] Such as figure 2 As shown, each pivot arm 7 includes two parallel arms, one end of the arm is fixedly connected to the rotating shaft 6, and the arm is in a Z shape, and the free end of the arm is bent downward by 90° and then extended horizontally to rotate the junction pipe 3 Slidingly connected to the horizontal extension section of the free end of the arm, the single intersection interface 4 is located on the side of the alternate intersection pipe 3 . The rotating shaft 6 is in the vertical direction, and the center of the rotating shaft 6 is provided with an axially through center hole. One end of the rotating shaft 6 is rotationally connected with a platform on the frame 1, and the other end of the rotating shaft 6 is connected with a driving device through a gear transmission mechanism. The driving device is a servo motor, and the servo motor is fixed on a pillar passing through the central hole of the rotating shaft and fixedly connected to the platform. Back...

Embodiment 3

[0035]The driving device is a servo motor. The rotating frame 2 is in the shape of a cross when viewed from the axial direction, and there are four alternating interchange pipes 3, which are respectively slidably connected to the four groups of arms of the rotating frame 2. Each group of arms is composed of three parallel arms, and the four groups of rotating arms 7 are connected to each other. Forming an included angle of 90°, two of the four alternate junctions 3 are alternate junctions with dark gray primer, two are alternate junctions with light gray primer, alternate junctions with dark gray primer and alternate junction with light gray primer Install at intervals on the rotating frame 2. Mobile seat slide rail 23 is horizontally arranged. When the new rotation junction pipe 3 is transferred to the nozzle of the paint delivery and mixing pipeline 28, the sealing ring on the single junction interface 4 can realize the sealing connection with the paint delivery and mixing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com