Battery disassembling clamp

A battery dismantling and jig technology, which is used in manufacturing tools, sawing machines, metal sawing equipment, etc., can solve problems such as easy cutting to battery cells, and achieve the effect of avoiding errors and accurate cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

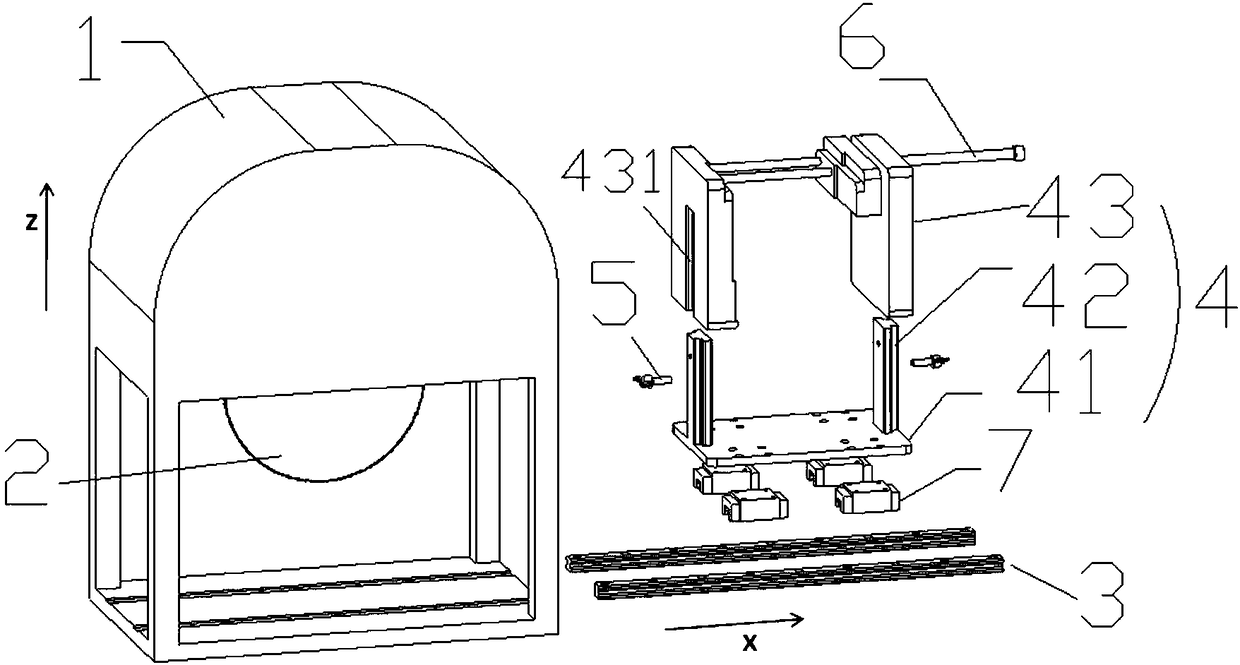

[0025] Such as figure 1 As shown, the battery disassembly jig provided in this embodiment includes a saw table 1, an electric saw 2 is arranged on the saw table 1, and rails 3 are provided at the bottom of the saw table 1. In this embodiment, the number of rails 3 is two strips and are arranged parallel to each other. The battery to be cut is placed on the slide table 4, and the position corresponding to the track 3 at the bottom of the support table 41 is provided with several slide heads 7 suitable for sliding along the track 3, and the slide table 4 passes the slide head 7 along the The track 3 drives the battery to slide, and the sliding platform 4 has a first state of moving below the electric saw 2 to make the electric saw 2 cut the battery, and a state of moving away from the electric saw to stop the electric saw from cutting the battery. second state.

[0026] In this embodiment, the electric saw 2 is arranged above the battery to be cut, the battery moves along the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com