A copy milling machine for milling workpieces of plastic material

A technology of plastic material and profiling milling machine, applied in milling machine equipment, milling machine equipment details, manufacturing tools, etc., can solve the problems of equipment cost processing, high technical requirements for operation, not conducive to cost efficiency requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

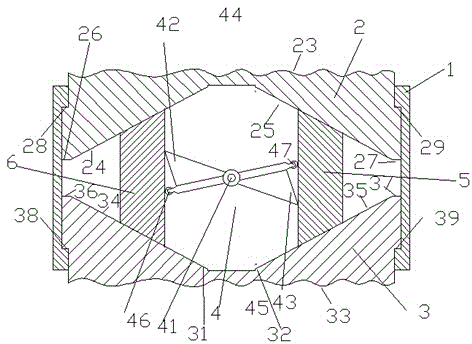

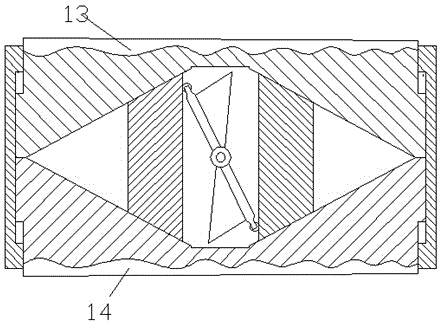

[0023] Combine below Figure 1-5 , the present invention will be described in detail. It should be pointed out that this specific description is not considered as any limitation to the present invention.

[0024] A profiling milling machine for milling workpieces of plastic materials, comprising two milling heads 803, 804 and a profiling system comprising a box 1, a first profiling module 2 and a second profiling module 3 The upper and lower side walls of the box body 1 are respectively provided with an upper slot 13 and a lower slot, the first module 2 and the second module 3 are symmetrically arranged in the box body 1, the first module 2 and the second module The two modules 3 respectively have a first cam edge 23 and a second cam edge 33, and the first cam edge 23 is used to drive the transverse feed of the first milling cutter head 803, thereby processing on the first workpiece part 801 Out of the groove on the curved surface, the second abutment edge 33 is used to driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com