Automatic laser welding machine for power battery cover plate and anti-explosion piece

A laser welding machine and power battery technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of difficult to ensure welding accuracy, high labor intensity, low placement efficiency, etc., and achieve secondary position adjustment , high degree of automation and high conveying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

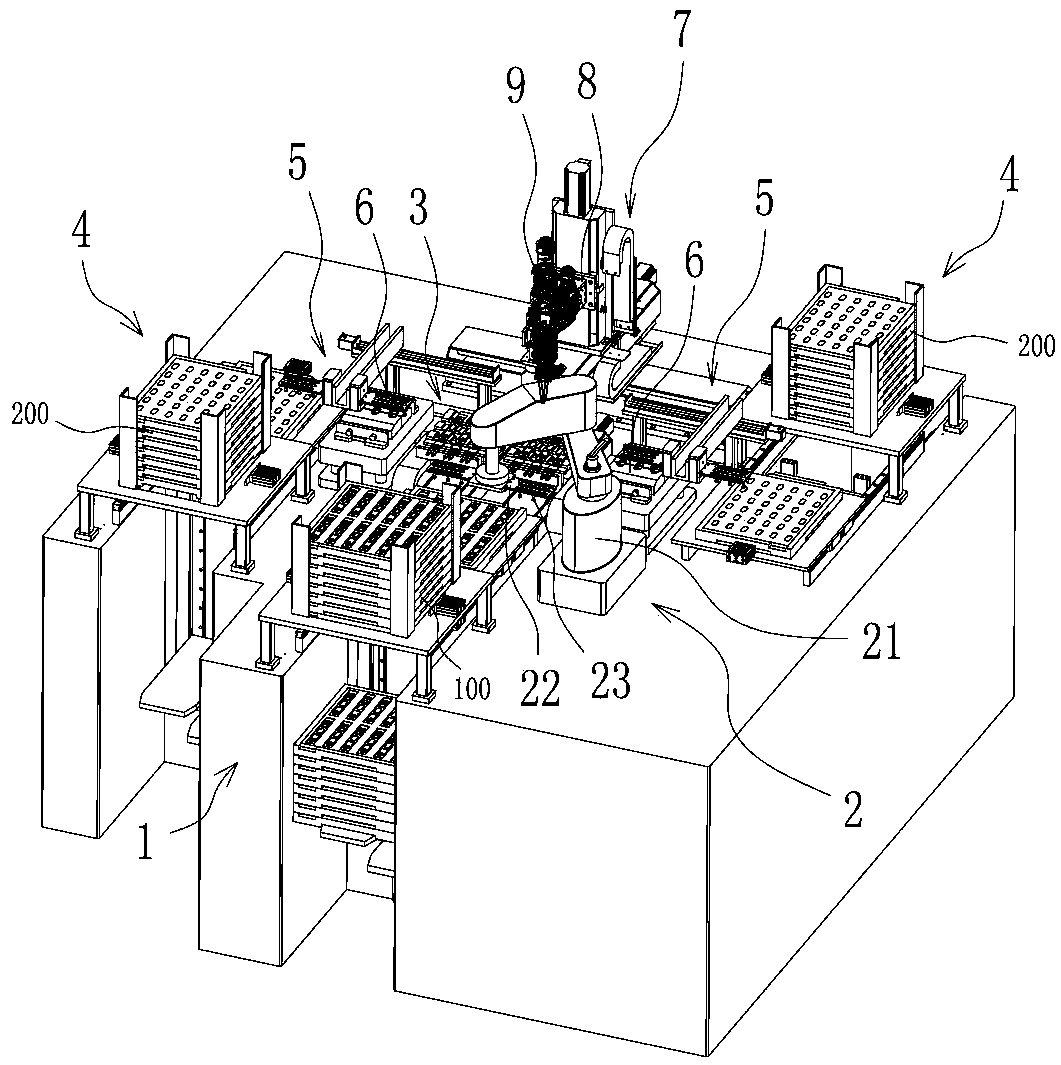

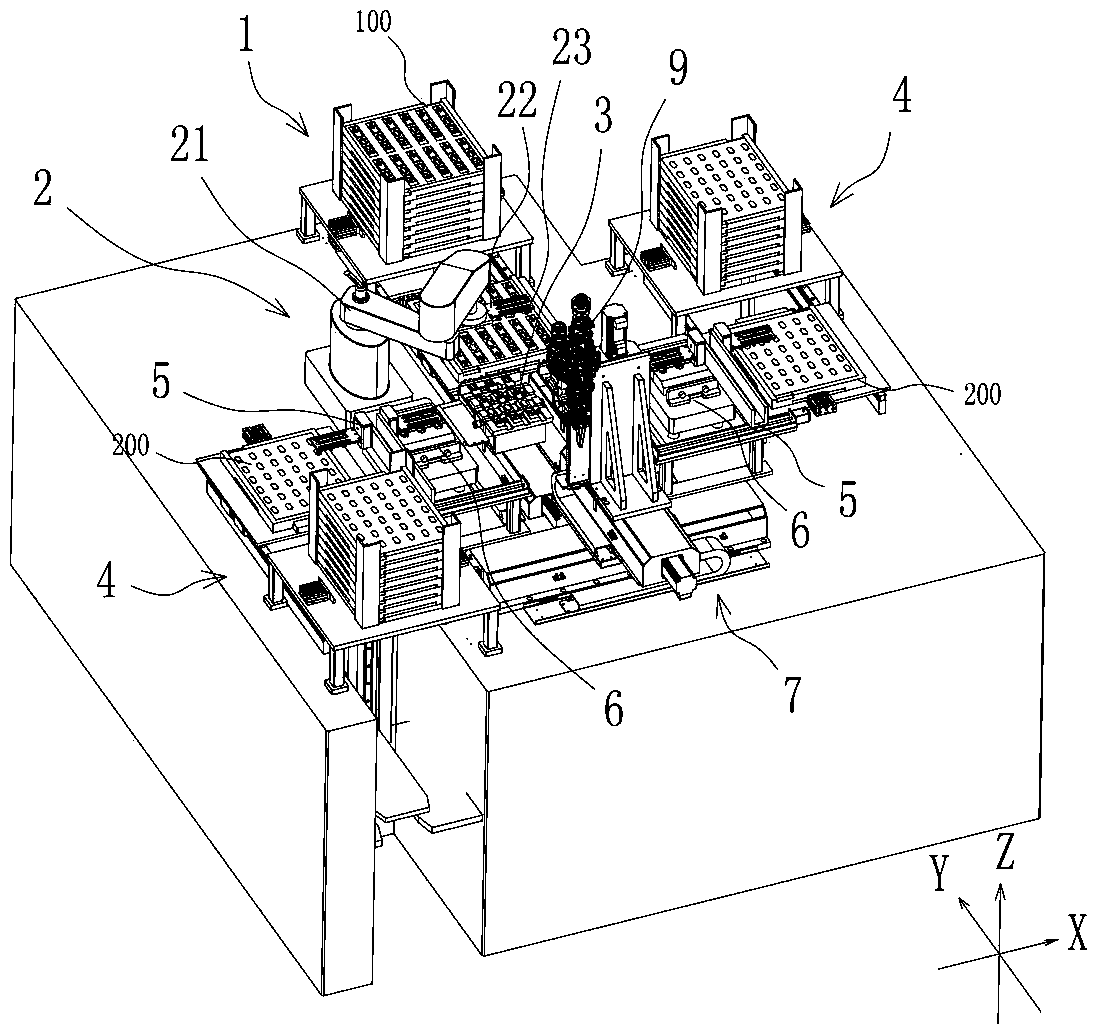

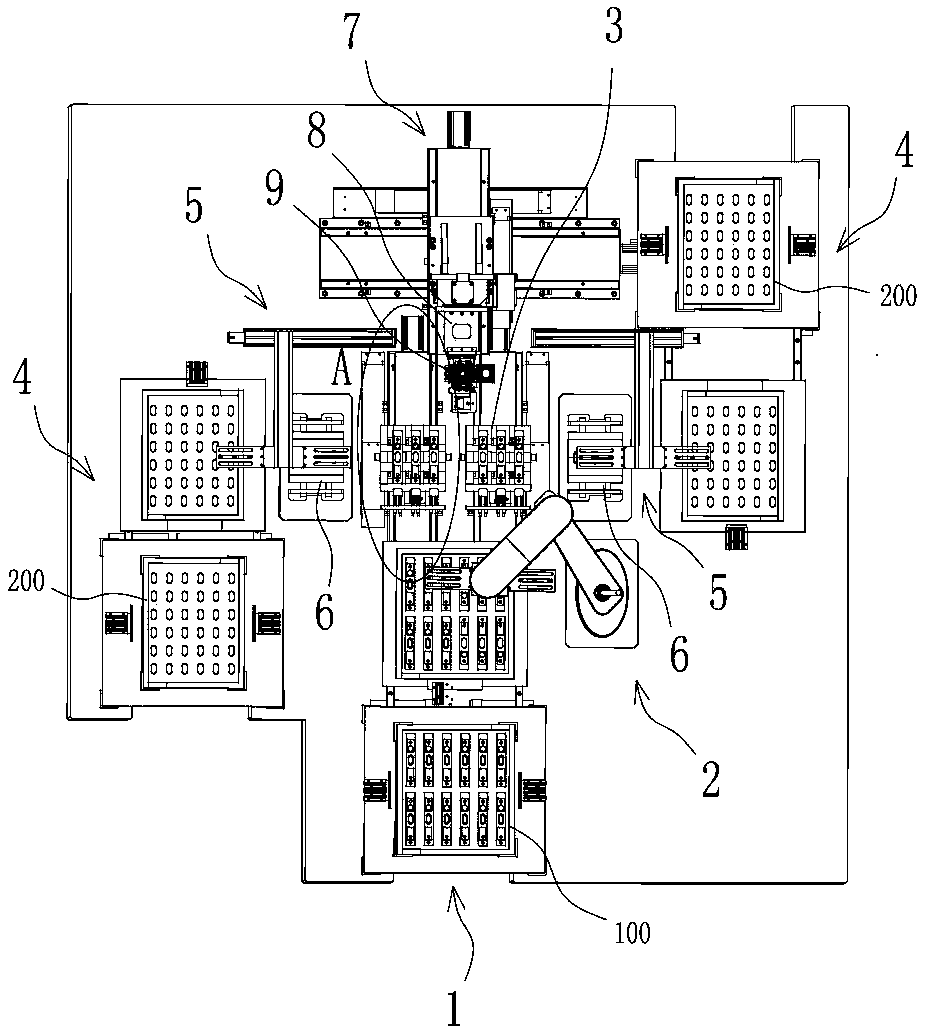

[0034] The structural principle and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0035] Such as Figure 1-Figure 8As shown, the present invention is an automatic laser welding machine for a power battery cover plate and an explosion-proof plate, including a cover plate storage tray conveying system 1, a cover plate transfer system 2, a cover plate positioning system 3, an explosion-proof plate storage plate conveying system 4, Explosion-proof disk transfer system 5, explosion-proof disk vibration adjustment system 6, XYZ axis transmission system 7, welding head 8 and laser welding system 9; of which:

[0036] The cover plate storage tray conveying system 1 is used to transport the cover plate storage tray 100 with the power battery cover plate to be welded to the working position of the cover plate transfer system 2, and then place the welded power battery cover plate The cover storage tr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap