Processing equipment for curve component and processing method of processing equipment

A technology for processing equipment and components, which is applied to the processing equipment and its processing field of curved components, and can solve the problem of lack of processing equipment for components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

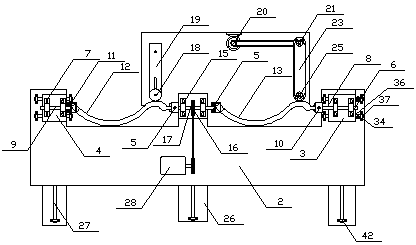

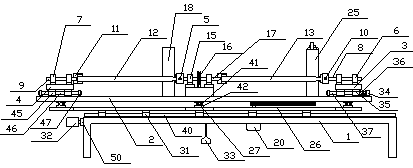

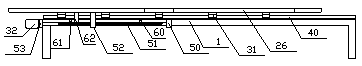

[0025] Embodiment 1: As shown in the figure, a processing equipment for curved components includes a frame 1, a longitudinal movement device and a lateral movement device are arranged on the frame 1, a transverse movement support 2 is arranged on the transverse movement device, and a transverse movement support 2 is arranged on the transverse movement support A driving device, a master device, a first slave device and a second slave device are arranged on the top, the drive device is connected to the master device, the first slave device is arranged on one side of the master device, and the second slave device is arranged on the other side of the master device. The driving device, the driving device drives the driven device to rotate through the components, and the frame 1 is also provided with a sanding device; the driving device is a variable speed motor 28, and the driving device includes: a main shaft 17, a belt pulley 16, and the main shaft 17 is provided with a belt pulley...

Embodiment 2

[0031] Embodiment 2: As shown in the figure, the processing method using the above-mentioned curved component processing equipment includes the following steps:

[0032] 1. According to the length of the processing components, adjust the distance between the driven rotating shaft 25 of the sanding machine and the master model 18, and install the master model bracket 19 and the master model 18 between the main shaft 17 and the second driven shaft 9 on rack 1;

[0033] Two, make a component model 12, it is installed between the chuck 5 of the main shaft 17 and the chuck 11 of the second driven shaft 9;

[0034] 3. Roughly process the component 13 to be processed with other woodworking tools, such as sawing the shape first, rounding the four corners with tools such as end milling, and installing it on the chuck 5 of the main shaft 17 and the first between the chucks 10 of the driven shaft 8, and ensure that the component model 12 is parallel to the component to be processed 13; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com