Transverse cutting mechanism

A technology of cross-cutting and cutting knife, which is applied in the direction of metal processing, cardboard articles, etc., which can solve the problems of affecting the stability of the equipment, affecting the cutting quality, and low cutting efficiency, and achieves small vibration, good cutting quality, and high-speed cutting. cut effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

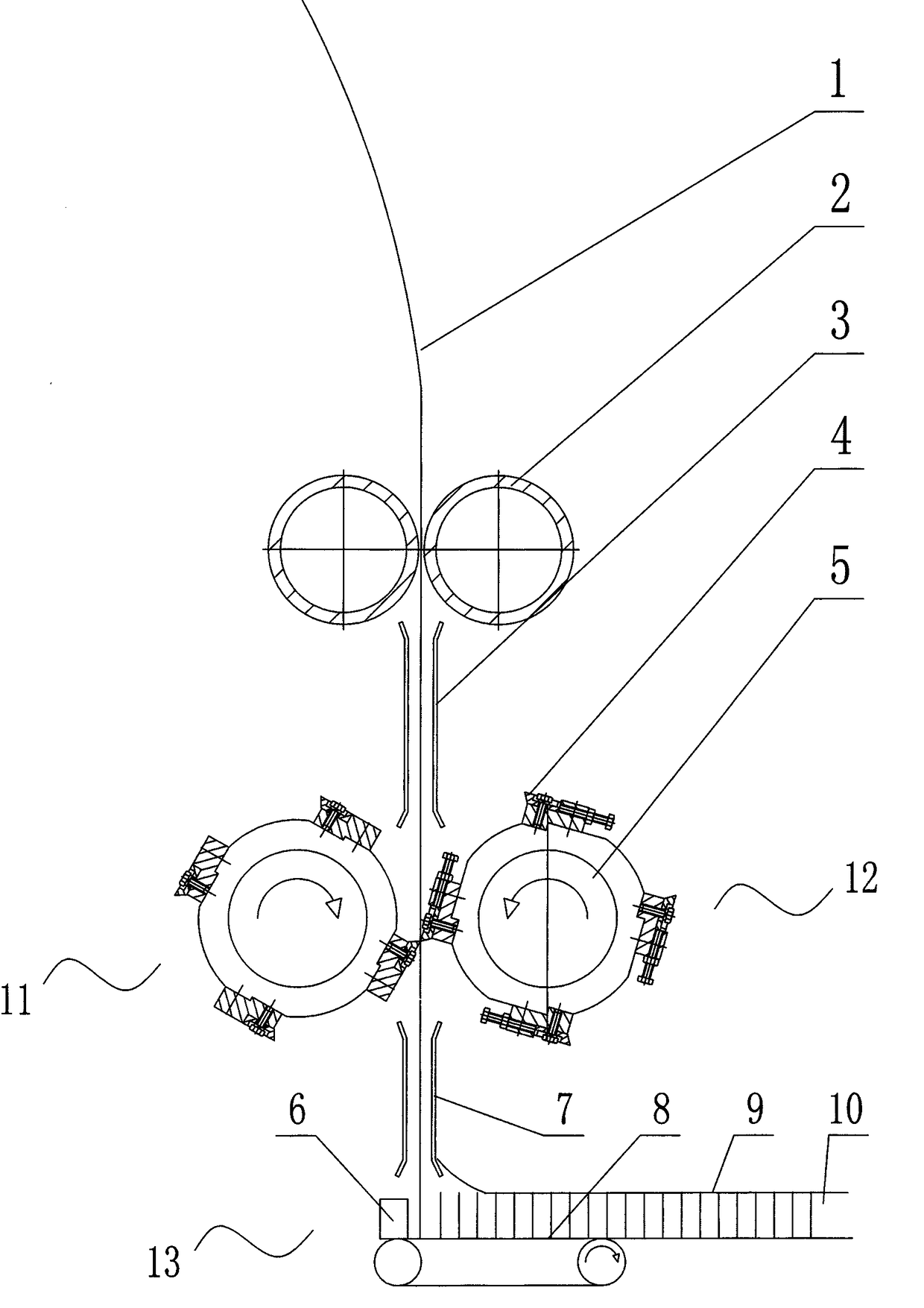

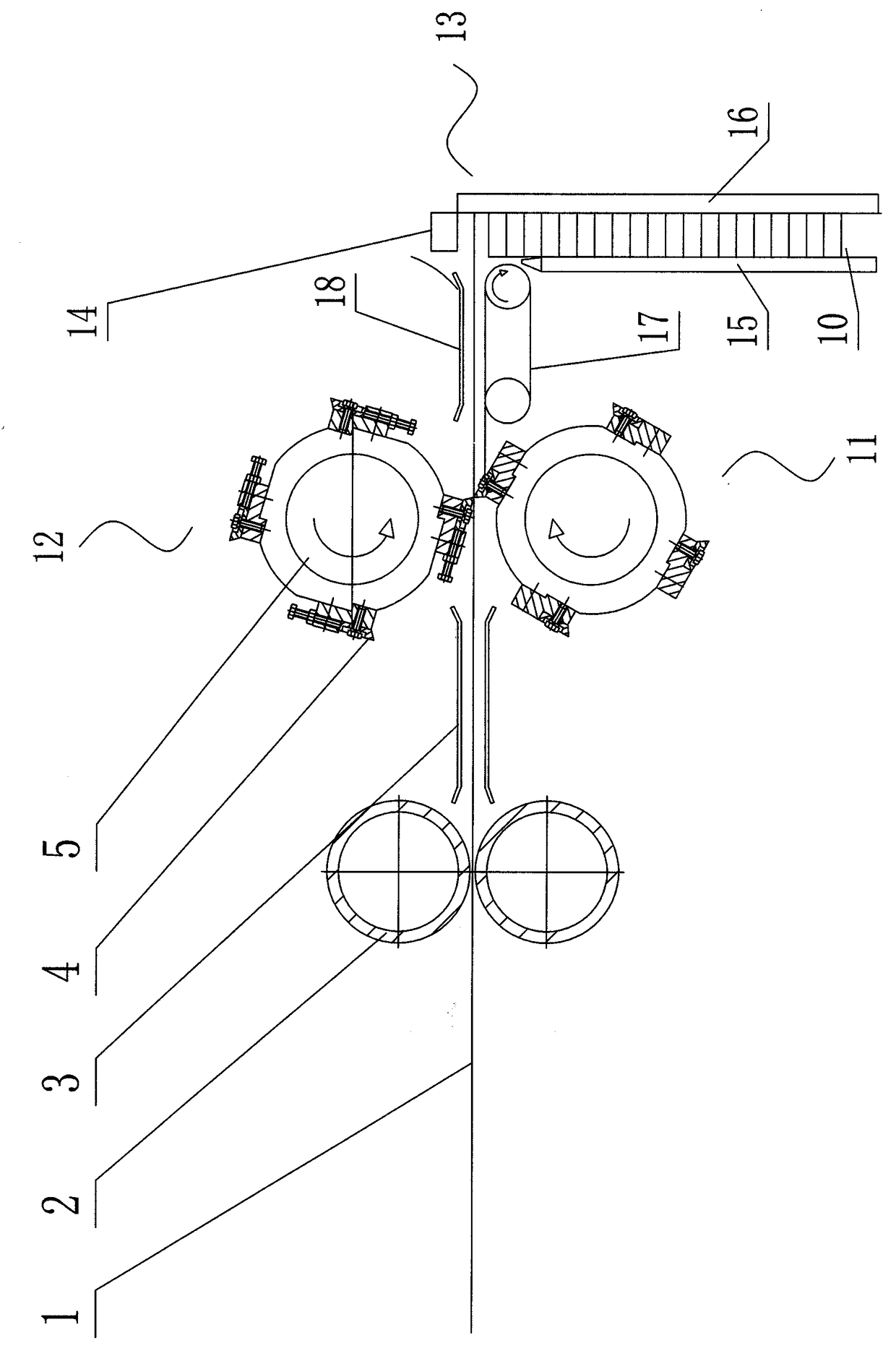

[0019] Embodiment two, adopt horizontal arrangement, refer to figure 2 , the feeding roller 2 and the paper core stacking composite part 13 are respectively arranged on both sides of the roller cutter group, the feeding roller 2 includes an upper roller and a lower roller arranged up and down, and the paper core stacking composite part 13 includes Vertically arranged stacking channel 10 and horizontally arranged conveyor belt 17, the stacking channel 10 is formed by a left baffle 15 and a right baffle 16, and the distance between the left baffle and the right baffle is the same as that of the paper core strip. The lengths are matched, and a briquetting block 14 is arranged above the stacking channel, and the briquetting block 14 is connected to a power source that drives it to lift. The power source can be a cylinder or a mechanical lift. A paper core strip deflector 18 is provided, and the paper core strip deflector 18 guides the cut paper core strip onto the conveyor belt 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com