A uniform drilling equipment for insulation board

A technology of drilling equipment and thermal insulation board, applied in metal processing and other directions, can solve the problems of inconsistent drilling size, time-consuming and labor-intensive, easy to shake, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

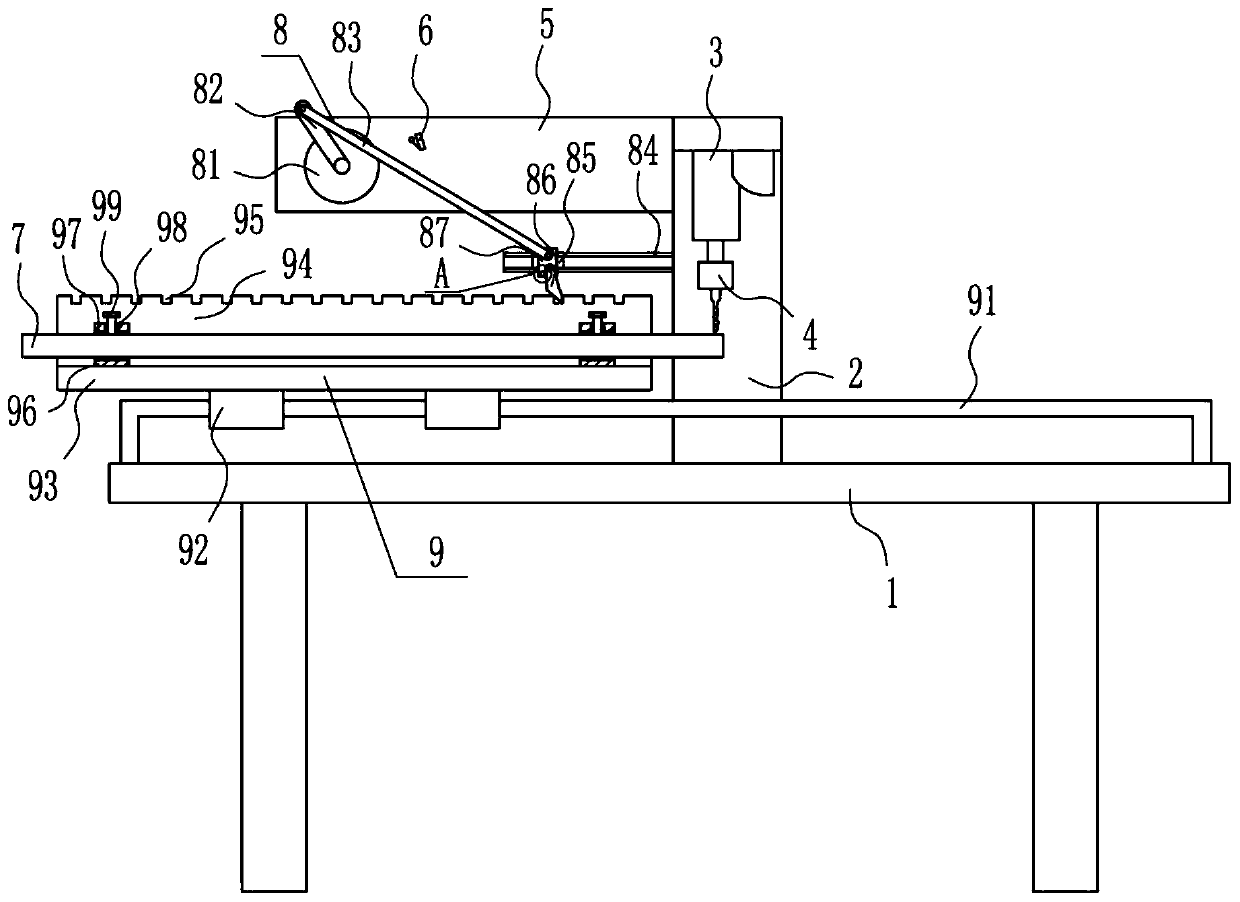

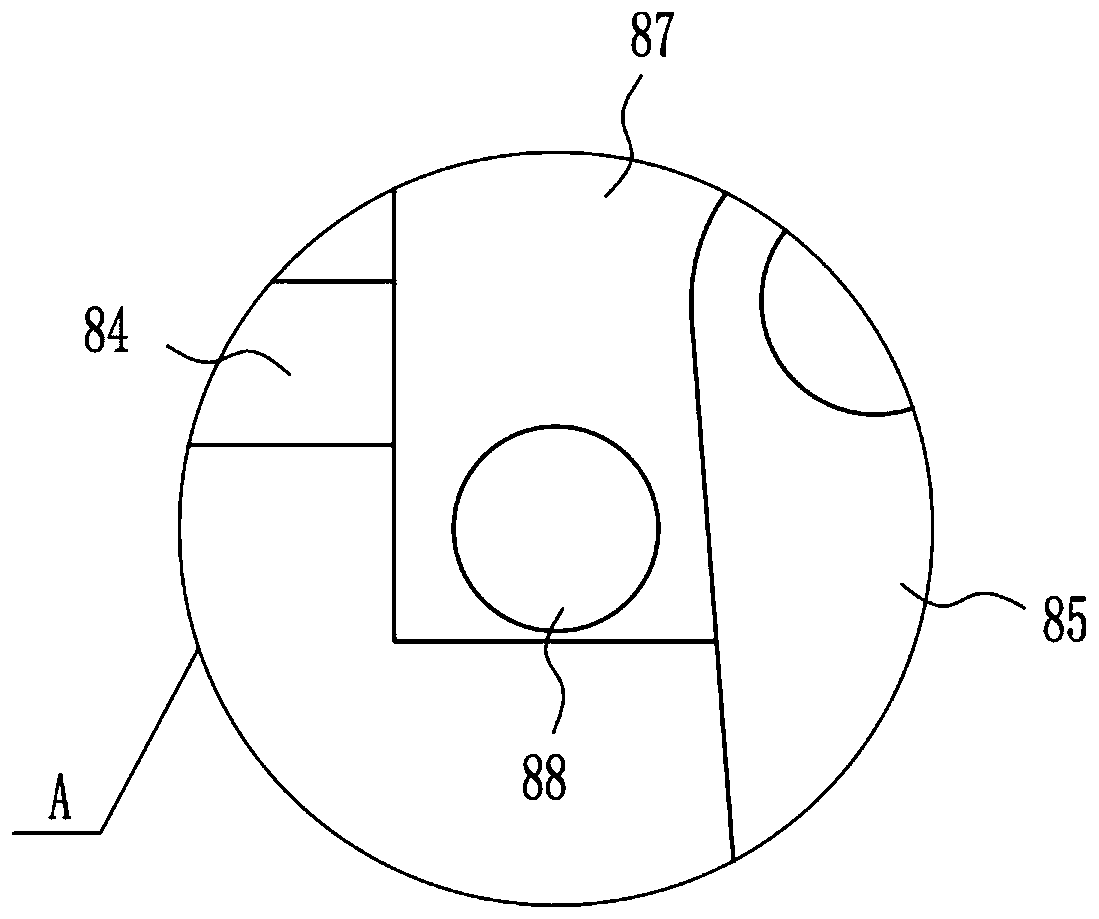

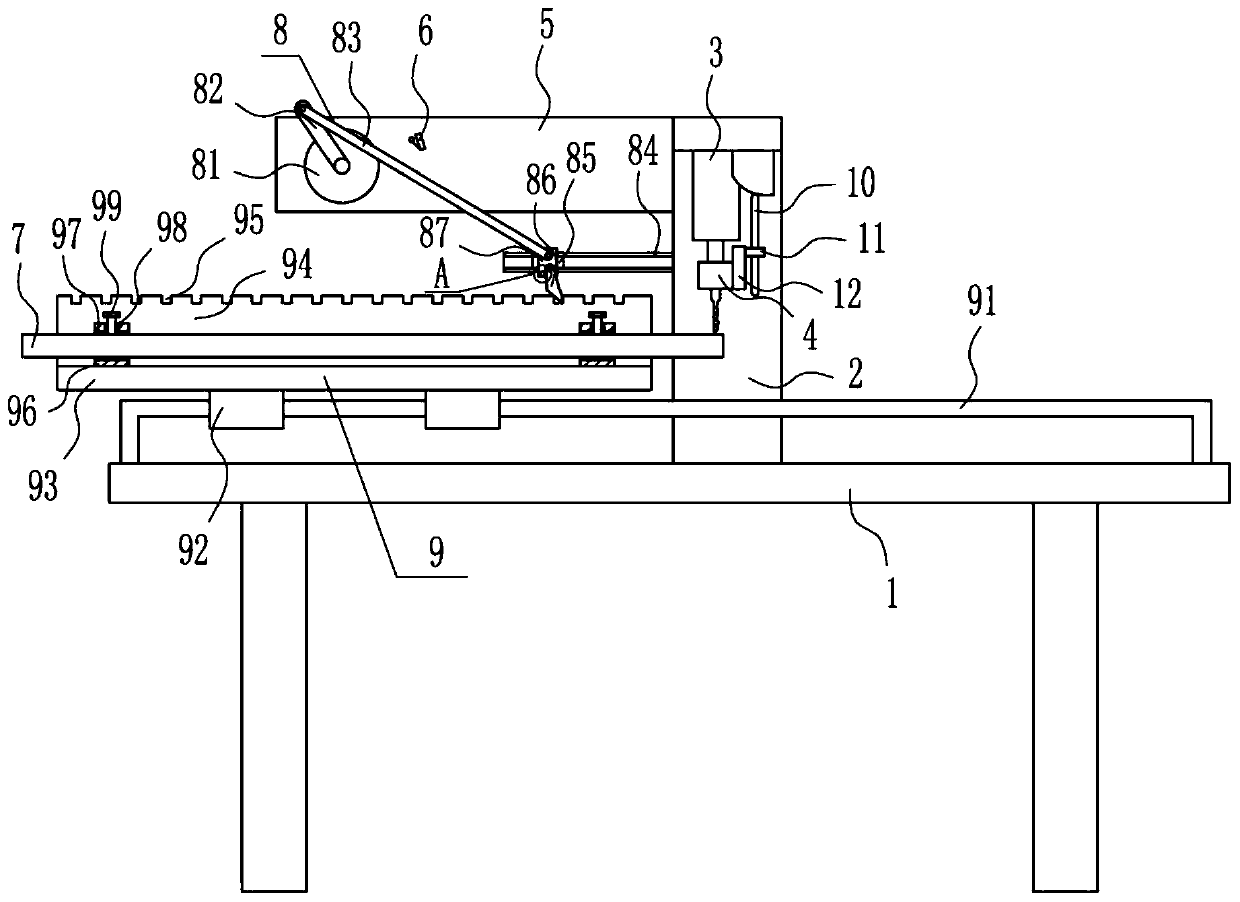

[0026] A kind of insulation board uniform drilling equipment, such as Figure 1-4 As shown, it includes console 1, type 7 plate 2, electric push rod 3, drilling machine 4, horizontal plate 5, button 6, driving device 8 and fixed transmission mechanism 9, and type 7 is installed on the top right side of console 1. Plate 2, 7-type plate 2 is equipped with an electric push rod 3 on the inner top, and a drilling machine 4 is installed on the telescopic rod of the electric push rod 3. A horizontal plate 5 is installed on the upper left side of the 7-type plate 2, and the front side of the horizontal plate 5 A driving device 8 is provided between the left side and the upper left side of the 7-type plate 2. A fixed transmission mechanism 9 is installed on the top of the console 1. The fixed transmission mechanism 9 is in contact with the driving device 8. The fixed mechanism is located on the front side of the 7-type plate 2. Button 6 is installed on the left side upper part of the f...

Embodiment 2

[0028] A kind of insulation board uniform drilling equipment, such as Figure 1-4 As shown, it includes console 1, type 7 plate 2, electric push rod 3, drilling machine 4, horizontal plate 5, button 6, driving device 8 and fixed transmission mechanism 9, and type 7 is installed on the top right side of console 1. Plate 2, 7-type plate 2 is equipped with an electric push rod 3 on the inner top, and a drilling machine 4 is installed on the telescopic rod of the electric push rod 3. A horizontal plate 5 is installed on the upper left side of the 7-type plate 2, and the front side of the horizontal plate 5 A driving device 8 is provided between the left side and the upper left side of the 7-type plate 2. A fixed transmission mechanism 9 is installed on the top of the console 1. The fixed transmission mechanism 9 is in contact with the driving device 8. The fixed mechanism is located on the front side of the 7-type plate 2. Button 6 is installed on the left side upper part of the f...

Embodiment 3

[0031]A kind of insulation board uniform drilling equipment, such as Figure 1-4 As shown, it includes console 1, type 7 plate 2, electric push rod 3, drilling machine 4, horizontal plate 5, button 6, driving device 8 and fixed transmission mechanism 9, and type 7 is installed on the top right side of console 1. Plate 2, 7-type plate 2 is equipped with an electric push rod 3 on the inner top, and a drilling machine 4 is installed on the telescopic rod of the electric push rod 3. A horizontal plate 5 is installed on the upper left side of the 7-type plate 2, and the front side of the horizontal plate 5 A driving device 8 is provided between the left side and the upper left side of the 7-type plate 2. A fixed transmission mechanism 9 is installed on the top of the console 1. The fixed transmission mechanism 9 is in contact with the driving device 8. The fixed mechanism is located on the front side of the 7-type plate 2. Button 6 is installed on the left side upper part of the fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com