Copying mechanism and method for manufacturing curved component through same

A technology of machinery and components, applied in the field of processing equipment, can solve the problem of lack of processing equipment for components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

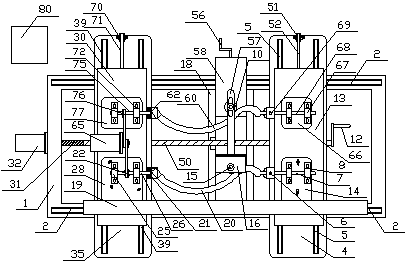

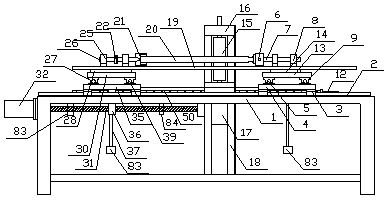

[0027] Embodiment 1, as shown in the figure, a profiling machine includes: a frame 1, a control box 80, a cutting device and a profiling device are arranged on the frame 1, and a longitudinal moving device and a profiling device are also arranged on the frame 1. The horizontal moving device is at least provided with a first active device, a second active device, a first driven device and a second driven device; the vertical moving device has two pieces, respectively the first longitudinal moving device and the second Vertically moving device, laterally moving device has two pieces, is respectively the first horizontally moving device and the second laterally moving device; The longitudinal linear bearing 3 and the first longitudinal linear bearing track 2, the first longitudinal linear bearing 3 is arranged on the first longitudinal linear bearing track 2, the first longitudinal linear bearing 3 is fixed under the first longitudinal moving platform 35, the first longitudinal li...

Embodiment 2

[0035] Embodiment 2, as shown in the figure, a method for making a curved member with the above profiling machine, comprising the following steps:

[0036] 1. According to the length of the member 20 to be processed, turn the longitudinal handle 12, adjust the distance between the first longitudinal moving device and the second longitudinal moving device, and install the member 12 to be processed on the chuck 21 of the first driving shaft 26 and Between the chucks 6 of the first driven shaft 7, and clamp it firmly through the claws on the chucks;

[0037] Two, make a curved member model 60, install it between the chuck 62 of the second driving shaft 75 and the chuck 69 of the second driven shaft 68, and parallel to the member 20 to be processed, pass through the chuck on the chuck The claws hold it firmly;

[0038] 3. Turn and move the handle 56 of the carriage 58, adjust the circular shaft 10 so that it is parallel to the cutter shaft 15, and the distance between the compone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com